Selection of optimal schemes for the inerting process of cargo tanks of gas carriers

DOI:

https://doi.org/10.15587/2706-5448.2024.310699Keywords:

cargo tanks, explosiveness of cargo tank atmosphere, inerting of cargo tanks, inerting using nitrogenAbstract

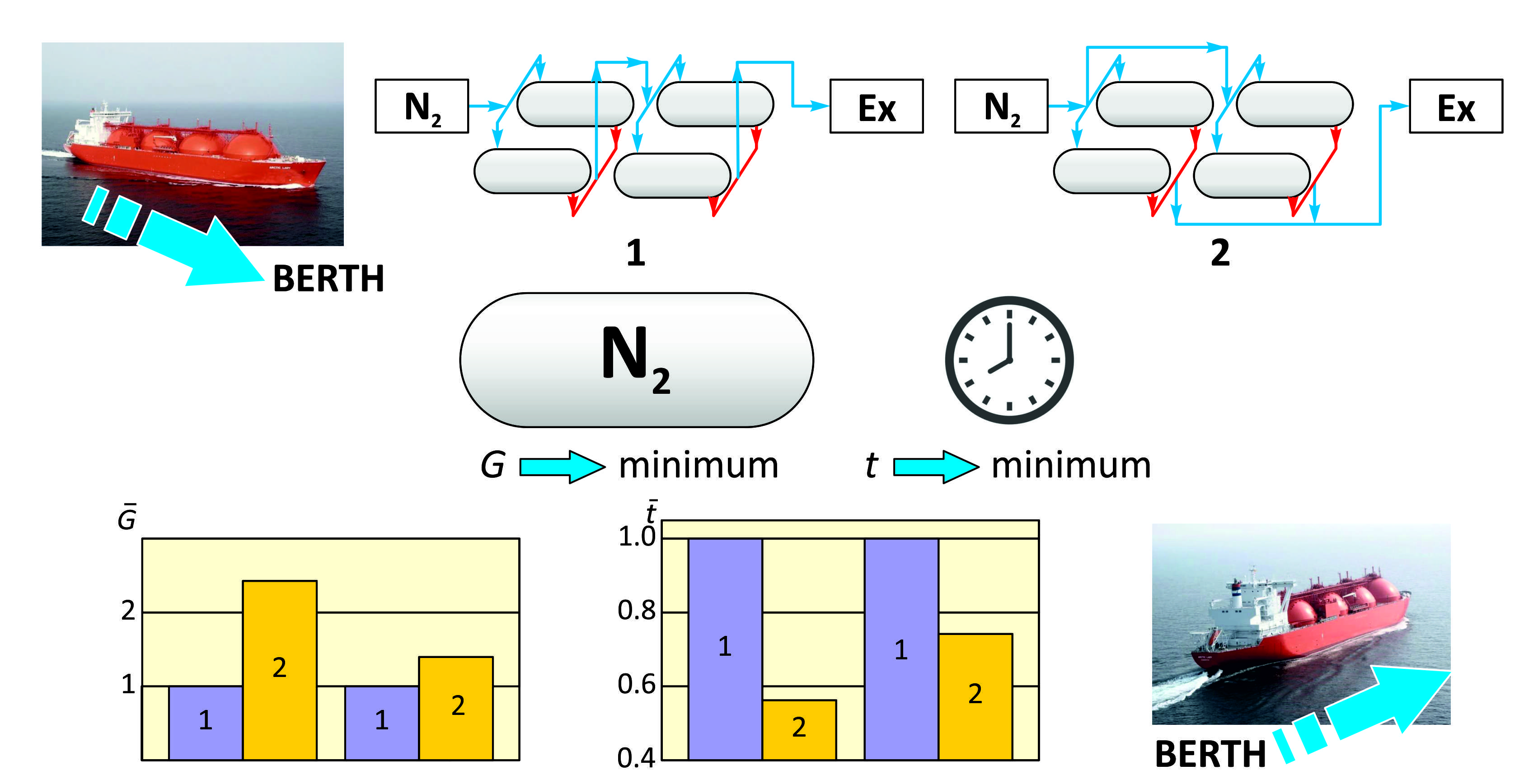

Recommendations are given for choosing the optimal schemes for the process of inerting cargo tanks of ships carrying liquefied gases. It was determined that one of the tasks that arise during the transportation of hydrocarbon cargoes (crude oil, petroleum products, and liquefied gases) is to ensure fire safety and prevent accidental explosions of cargo vapors in cargo tanks. Processes that occur during cargo operations on ships transporting oil products and liquefied gases are considered. The critical composition of the mixture of oxygen (entering the cargo tanks with air) and cargo vapors (remaining in the tanks after the cargo is unloaded) is indicated, at which a flash and explosion may occur. It was determined that the main technological operation that prevents spontaneous ignition of cargo vapors in cargo tanks is their inerting using nitrogen. The main advantages and disadvantages of the schemes for inerting cargo tanks are considered and determined: cascade, semi-cascade and parallel. The effective use of these schemes is based on the consumption of nitrogen, the amount of which is necessary for inerting, as well as the duration of the inerting process. The results of determining these indicators for a group of gas carriers with a cargo capacity of 38,646–62,233 m3 are given. At the same time, it is stated that the lowest consumption of nitrogen is necessary to ensure the process of inerting according to the cascade scheme. It was established that semi-cascade and parallel inerting schemes require an increase in the amount of nitrogen by 1.74–2.42 times and by 1.28–1.83 times, respectively. It was also established that the cascade scheme of inerting requires more time for its implementation. The duration of inerting according to the semi-cascade and parallel scheme is reduced and is 0.43–0.64 and 0.58–0.75 times in comparison with the cascade scheme.

References

- Khlopenko, M., Gritsuk, I., Sharko, O., Appazov, E. (2024). Increasing the accuracy of the vessel’s course orientation. Technology Audit and Production Reserves, 1 (2 (75)), 25–30. https://doi.org/10.15587/2706-5448.2024.298518

- Madey, V. (2022). Assessment of the efficiency of biofuel use in the operation of marine diesel engines. Technology Audit and Production Reserves, 2 (1 (64)), 34–41. https://doi.org/10.15587/2706-5448.2022.255959

- Maryanov, D. (2021). Development of a method for maintaining the performance of drilling fluids during transportation by Platform Supply Vessel. Technology Audit and Production Reserves, 5 (2 (61)), 15–20. https://doi.org/10.15587/2706-5448.2021.239437

- Maryanov, D. (2022). Control and regulation of the density of technical fluids during their transportation by sea specialized vessels. Technology Audit and Production Reserves, 1 (2 (63)), 19–25. https://doi.org/10.15587/2706-5448.2022.252336

- Sagin, S. V., Karianskyi, S., Sagin, S. S., Volkov, O., Zablotskyi, Y., Fomin, O. et al.(2023). Ensuring the safety of maritime transportation of drilling fluids by platform supply-class vessel. Applied Ocean Research, 140, 103745. https://doi.org/10.1016/j.apor.2023.103745

- Sagin, A. S., Zablotskyi, Y. V. (2021). Reliability maintenance of fuel equipment on marine and inland navigation vessels. The Austrian Journal of Technical and Natural Sciences, 7-8, 14–17. https://doi.org/10.29013/ajt-21-7.8-14-17

- Chang, Z., He, X., Fan, H., Guan, W., He, L. (2023). Leverage Bayesian Network and Fault Tree Method on Risk Assessment of LNG Maritime Transport Shipping Routes: Application to the China–Australia Route. Journal of Marine Science and Engineering, 11 (9), 1722. https://doi.org/10.3390/jmse11091722

- Lee, K. (2024). Development of Hardware-in-the-Loop Simulation Test Bed to Verify and Validate Power Management System for LNG Carriers. Journal of Marine Science and Engineering, 12 (7), 1236. https://doi.org/10.3390/jmse12071236

- Ershov, M. A., Grigorieva, E. V., Abdellatief, T. M. M., Kapustin, V. M., Abdelkareem, M. A., Kamil, M., Olabi, A. G. (2021). Hybrid low-carbon high-octane oxygenated gasoline based on low-octane hydrocarbon fractions. Science of The Total Environment, 756, 142715. https://doi.org/10.1016/j.scitotenv.2020.142715

- Sagin, S. V., Sagin, S. S., Fomin, O., Gaichenia, O., Zablotskyi, Y., Píštěk, V., Kučera, P. (2024). Use of biofuels in marine diesel engines for sustainable and safe maritime transport. Renewable Energy, 224, 120221. https://doi.org/10.1016/j.renene.2024.120221

- Sagin, S., Kuropyatnyk, O., Sagin, A., Tkachenko, I., Fomin, O., Píštěk, V., Kučera, P. (2022). Ensuring the Environmental Friendliness of Drillships during Their Operation in Special Ecological Regions of Northern Europe. Journal of Marine Science and Engineering, 10 (9), 1331. https://doi.org/10.3390/jmse10091331

- Sagin, S. V., Kuropyatnyk, O. A., Zablotskyi, Yu. V., Gaichenia, O. V. (2022). Supplying of Marine Diesel Engine Ecological Parameters. Naše more, 69 (1), 53–61. https://doi.org/10.17818/nm/2022/1.7

- Bogdevicius, M., Semaskaite, V., Paulauskiene, T., Uebe, J. (2024). Impact and Technical Solutions of Hydrodynamic and Thermodynamic Processes in Liquefied Natural Gas Regasification Process. Journal of Marine Science and Engineering, 12 (7), 1164. https://doi.org/10.3390/jmse12071164

- Manos, A., Lyridis, D., Prousalidis, J., Sofras, E. (2023). Investigating the Operation of an LNG Carrier as a Floating Power Generating Plant (FPGP). Journal of Marine Science and Engineering, 11 (9), 1749. https://doi.org/10.3390/jmse11091749

- Zablotsky, Yu. V., Sagin, S. V. (2016). Enhancing Fuel Efficiency and Environmental Specifications of a Marine Diesel When using Fuel Additives. Indian Journal of Science and Technology, 9, 353–362. https://doi.org/10.17485/ijst/2016/v9i46/107516

- Zablotsky, Yu. V., Sagin, S. V. (2016). Maintaining Boundary and Hydrodynamic Lubrication Modes in Operating High-pressure Fuel Injection Pumps of Marine Diesel Engines. Indian Journal of Science and Technology, 9, 208–216. https://doi.org/10.17485/ijst/2016/v9i20/94490

- Sagin, S. V., Semenov, O. V. (2016). Motor Oil Viscosity Stratification in Friction Units of Marine Diesel Motors. American Journal of Applied Sciences, 13 (2), 200–208. https://doi.org/10.3844/ajassp.2016.200.208

- Salova, T., Lekomtsev, P., Likhanov, V., Lopatin, O., Belov, E. (2023). Development of calculation methods and optimization of working processes of heat engines. AIP Conference Proceedings, 2700, 050015. https://doi.org/10.1063/5.0137793

- Sagin, S. V., Semenov, O. V. (2016). Marine Slow-Speed Diesel Engine Diagnosis with View to Cylinder Oil Specification. American Journal of Applied Sciences, 13 (5), 618–627. https://doi.org/10.3844/ajassp.2016.618.627

- Stoliaryk, T. (2022). Analysis of the operation of marine diesel engines when using engine oils with different structural characteristics. Technology Audit and Production Reserves, 5 (1 (67)), 22–32. https://doi.org/10.15587/2706-5448.2022.265868

- Sagin, S. V., Solodovnikov, V. G. (2015). Cavitation Treatment of High-Viscosity Marine Fuels for Medium-Speed Diesel Engines. Modern Applied Science, 9, 269–278. https://doi.org/10.5539/mas.v9n5p269

- Sagin, S. V., Solodovnikov, V. G. (2017). Estimation of Operational Properties of Lubricant Coolant Liquids by Optical Methods. International Journal of Applied Engineering Research, 12, 8380–8391.

- Sagin, S. V. (2020). Determination of the optimal recovery time of the rheological characteristics of marine diesel engine lubricating oils. Materials of the International Conference «Process Management and Scientific Developments», Part 4, 195–202. https://doi.org/10.34660/INF.2020.4.52991

- Maryanov, D. (2022). Reduced energy losses during transportation of drilling fluid by Platform Supply Vessels. Technology Audit and Production Reserves, 2 (1 (64)), 42–50. https://doi.org/10.15587/2706-5448.2022.256473

- Sagin, S., Karianskyi, S., Madey, V., Sagin, A., Stoliaryk, T., Tkachenko, I. (2023). Impact of Biofuel on the Environmental and Economic Performance of Marine Diesel Engines. Journal of Marine Science and Engineering, 11 (1), 120. https://doi.org/10.3390/jmse11010120

- Kuropyatnyk, O. A. (2020). Reducing the emission of nitrogen oxides from marine diesel engines. International Conference «Scientific research of the SCO countries: synergy and integration», 154–160. https://doi.org/10.34660/INF.2020.24.53689

- Kuropyatnyk, O. A., Sagin, S. V. (2019). Exhaust Gas Recirculation as a Major Technique Designed to Reduce NOх Emissions from Marine Diesel Engines. Naše More, 66 (1), 1–9. https://doi.org/10.17818/nm/2019/1.1

- Gorb, S., Levinskyi, M., Budurov, M. (2022). Sensitivity Optimisation of a Main Marine Diesel Engine Electronic Speed Governor. Scientific Horizons, 24 (11), 9–19. https://doi.org/10.48077/scihor.24(11).2021.9-19

- Sagin, S., Madey, V., Sagin, A., Stoliaryk, T., Fomin, O., Kučera, P. (2022). Ensuring Reliable and Safe Operation of Trunk Diesel Engines of Marine Transport Vessels. Journal of Marine Science and Engineering, 10 (10), 1373. https://doi.org/10.3390/jmse10101373

- Fischer, D., Vith, W., Unger, J. L. (2024). Assessing Particulate Emissions of Novel Synthetic Fuels and Fossil Fuels under Different Operating Conditions of a Marine Engine and the Impact of a Closed-Loop Scrubber. Journal of Marine Science and Engineering, 12 (7), 1144. https://doi.org/10.3390/jmse12071144

- Minchev, D. S., Varbanets, R. A., Alexandrovskaya, N. I., Pisintsaly, L. V. (2021). Marine diesel engines operating cycle simulation for diagnostics issues. Acta Polytechnica, 61 (3), 435–447. https://doi.org/10.14311/ap.2021.61.0435

- Sagin, S. V., Sagin, S. S., Madey, V. (2023). Analysis of methods of managing the environmental safety of the navigation passage of ships of maritime transport. Technology Audit and Production Reserves, 4 (3 (72)), 33–42. https://doi.org/10.15587/2706-5448.2023.286039

- Visan, N. A., Niculescu, D. C., Ionescu, R., Dahlin, E., Eriksson, M., Chiriac, R. (2024). Study of Effects on Performances and Emissions of a Large Marine Diesel Engine Partially Fuelled with Biodiesel B20 and Methanol. Journal of Marine Science and Engineering, 12 (6), 952. https://doi.org/10.3390/jmse12060952

- Xiao, X., Xu, X., Wang, Z., Liu, C., He, Y. (2023). Research on a Novel Combined Cooling and Power Scheme for LNG-Powered Ship. Journal of Marine Science and Engineering, 11 (3), 592. https://doi.org/10.3390/jmse11030592

- Varbanets, R., Fomin, O., Píštěk, V., Klymenko, V., Minchev, D., Khrulev, A. et al. (2021). Acoustic Method for Estimation of Marine Low-Speed Engine Turbocharger Parameters. Journal of Marine Science and Engineering, 9 (3), 321. https://doi.org/10.3390/jmse9030321

- Sagin, S. V., Stoliaryk, T. O. (2021). Comparative assessment of marine diesel engine oils. The Austrian Journal of Technical and Natural Sciences, 7-8, 29–35. https://doi.org/10.29013/ajt-21-7.8-29-35

- Neumann, S., Varbanets, R., Minchev, D., Malchevsky, V., Zalozh, V. (2022). Vibrodiagnostics of marine diesel engines in IMES GmbH systems. Ships and Offshore Structures, 18 (11), 1535–1546. https://doi.org/10.1080/17445302.2022.2128558

- Lopatin, O. P. (2024). Investigation of the combustion process in a dual-fuel engine. Journal of Physics: Conference Series, 2697 (1), 012079. https://doi.org/10.1088/1742-6596/2697/1/012079

- Sagin, S., Madey, V., Stoliaryk, T. (2021). Analysis of mechanical energy losses in marine diesels. Technology Audit and Production Reserves, 5 (2 (61)), 26–32. https://doi.org/10.15587/2706-5448.2021.239698

- Sagin, S. V. (2019). Decrease in mechanical losses in high-pressure fuel equipment of marine diesel engines. Materials of the International Conference «Scientific research of the SCO countries: synergy and integration». Part 1, 139–145. https://doi.org/10.34660/INF.2019.15.36258

- Gorb, S., Popovskii, A., Budurov, M. (2023). Adjustment of speed governor for marine diesel generator engine. International Journal of GEOMATE, 25 (109), 125–132. https://doi.org/10.21660/2023.109.m2312

- Sagin, S. V., Kuropyatnyk, O. A. (2021). Using exhaust gas bypass for achieving the environmental performance of marine diesel engines. Austrian Journal of Technical and Natural Sciences. Scientific journal, 7-8, 36–43. https://doi.org/10.29013/AJT-21-7.8-36-43

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Oleksii Matieiko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.