Визначення енергоефективності грануляційного обладнання на основі ексергетичного аналізу

DOI:

https://doi.org/10.15587/2706-5448.2024.311777Ключові слова:

гранулювання мінеральних добрив, гранулятор, карбамід, приллювання, обкочування, активна гідродинаміка, гранулоутворення, ексергіяАнотація

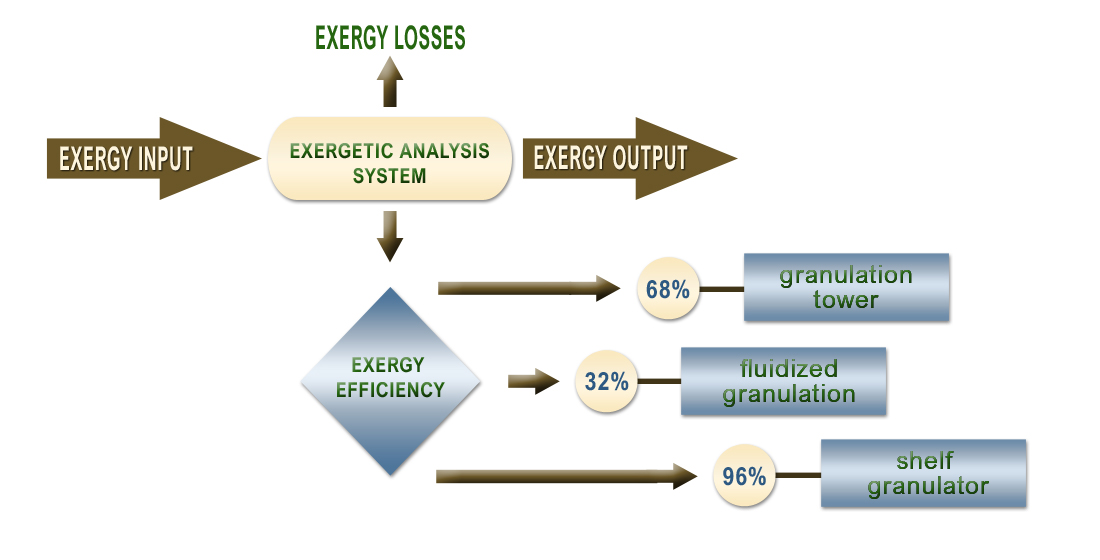

Об’єктом дослідження є процес гранулювання мінеральних добрив шляхом застосування методів обкочування та приллювання, а також у псевдозріджених та завислих шарах з активною гідродинамікою потоків. Зазначено, що розвиток основних технологічних стадій виробництва гранульованих добрив треба спрямувати на вдосконалення апаратурного оформлення грануляторів, встановлення найбільш раціональних режимно-технологічних параметрів ведення процесу з метою підвищення його ефективності та зменшення енергетичних витрат. Зазначено, що основними показниками ефективності грануляційних установок, що використовують тепло, є економічні витрати, втрати ексергії, а також приведені витрати. Представлено методику ексергетичного аналізу щодо оцінки енергетичних витрат на процеси гранулювання у різних типів грануляторів, яка дозволяє обґрунтувати вибір раціональних параметрів зазначених процесів, враховуючи енергетичні витрати та ефективність обладнання. Представлені рівняння для визначення величини ексергії матеріальних потоків та ексергетичних втрат, що обумовлені теплообміном при кінцевих різницях температур технологічних потоків на вході в апарат та виході із нього. Представлено рівняння для визначення ексергетичного к.к.д., який характеризує енергоефективність технічної системи. Чим менша різниця температур для технологічних потоків на виході з апарата, тим менші ексергетичні втрати, вище значення ексергетичного к.к.д. і, відповідно, апарат буде мати більшу енергоефективність. Проведено ексергетичний аналіз процесів гранулювання у грануляційних баштах без охолоджувача, у грануляційних баштах з охолоджувачем, апаратах киплячого шару та багатоступеневих (поличних) апаратах. Аналіз показав, що ексергетичний к.к.д. для вказаних грануляційних установок дорівнює відповідно: 64 %, 71 %, 32 % та 96 %. Отримані результати дослідження можуть бути застосовані в умовах виробництва, де використовуються грануляційні башти та апарати киплячого чи зваженого шарів. Підприємства, які планують знизити енерговитрати та підвищити екологічну безпеку своїх технологічних процесів, можуть впроваджувати вдосконалення на основі запропонованих методик та рівнянь. Застосування результатів дослідження сприятиме вибору більш раціональних показників процесу отримання гранул, що дозволить збільшити продуктивність та якість кінцевого продукту.

Спонсор дослідження

- This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 871072. Additionally, this research work has been carried out within the project «Fulfillment of tasks of the perspective plan of development of a scientific direction «Technical sciences» Sumy State University» (State Reg. No. 0121U112684) funded by the Ministry of Education and Science of Ukraine.

Посилання

- Arthur, T. B., Chauhan, J., Rahmanian, N. (2022). Process Simulation of Fluidized Bed Granulation: Effect of Process Parameters on Granule Size Distribution. Chemical Engineering Transactions, 95, 241–246. https://doi.org/10.3303/CET2295041

- Artyukhov, A. E., Vakal, S. V., Yanovska, A. O., Shkola, V. Y., Vakal, V. S., Yarova, T. Y. (2020). The Investigation of Nanoporous Structure Morphology and Elemental Composition of Organo-mineral Fertilizer Granules. Journal of Nano- and Electronic Physics, 12 (6). https://doi.org/10.21272/jnep.12(6).06039

- Askarishahi, M., Salehi, M.-S., Radl, S. (2023). Challenges in the Simulation of Drying in Fluid Bed Granulation. Processes, 11 (2), 569. https://doi.org/10.3390/pr11020569

- Azadi, M., Hormozi, F., Sanaei-Moghadam, M., Sarkandy, S. Y. (2024). The role of adding nanoparticles and surfactant to the enzyme liquid binder in fluidized bed granulation process. Powder Technology, 435, 119436. https://doi.org/10.1016/j.powtec.2024.119436

- Jarchow, M. E., Liebman, M. (2012). Nitrogen fertilization increases diversity and productivity of prairie communities used for bioenergy. GCB Bioenergy, 5 (3), 281–289. https://doi.org/10.1111/j.1757-1707.2012.01186.x

- Barrasso, D., Eppinger, T., Pereira, F. E., Aglave, R., Debus, K., Bermingham, S. K., Ramachandran, R. (2015). A multi-scale, mechanistic model of a wet granulation process using a novel bi-directional PBM–DEM coupling algorithm. Chemical Engineering Science, 123, 500–513. https://doi.org/10.1016/j.ces.2014.11.011

- Bellinghausen, S., Gavi, E., Jerke, L., Barrasso, D., Salman, A. D., Litster, J. D. (2022). Model-driven design using population balance modelling for high-shear wet granulation. Powder Technology, 396, 578–595. https://doi.org/10.1016/j.powtec.2021.10.028

- Cotabarren, I. M., Moreno, J., Martínez, A. L., Cabrera, F. A., Piña, J. (2019). Valorization of anaerobic digestion liquid residue through the production of organic fertilizer by fluidized bed granulation. Chemical Engineering Research and Design, 147, 113–121. https://doi.org/10.1016/j.cherd.2019.04.043

- Diez, E., Meyer, K., Bück, A., Tsotsas, E., Heinrich, S. (2018). Influence of process conditions on the product properties in a continuous fluidized bed spray granulation process. Chemical Engineering Research and Design, 139, 104–115. https://doi.org/10.1016/j.cherd.2018.09.032

- Nichvolodin, K., Sklabinskyi, V. (2023). Determination of the heat transfer coefficient between pellets and air during the modernization of a pelletizing tower based on industrial research. Technology Audit and Production Reserves, 6 (3 (74)), 18–21. https://doi.org/10.15587/2706-5448.2023.293264

- Nadhem, A.-K. M., Skydanenko, M., Ostroha, R., Neshta, A., Yukhymenko, M., Yakhnenko, S. et al. (2022). Research of plate granulator operation modes in the production of coarse carbamide granules. Technology Audit and Production Reserves, 1 (3 (63)), 12–15. https://doi.org/10.15587/2706-5448.2022.252367

- Moure Abelenda, A., Amaechi, C. V. (2022). Manufacturing of a Granular Fertilizer Based on Organic Slurry and Hardening Agent. Inventions, 7 (1), 26. https://doi.org/10.3390/inventions7010026

- Yukhimenko, N., Vakal, S. (2016). The exergy analysis of energy efficiency of the technology of granulated phosphorus-potassium fertilizers. Eastern-European Journal of Enterprise Technologies, 5 (6 (83)), 4–10. https://doi.org/10.15587/1729-4061.2016.77182

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Ruslan Ostroha, Mykola Yukhymenko, Dmytro Myshchenko, Maksym Skydanenko, Oleksandr Ivchenko, Dmytro Zhyhylii, Liudmyla Ponomarova, Jozef Bocko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.