Comparison of technological operations in processing alfalufer hay in terms of their impact on forage quality and quantity

DOI:

https://doi.org/10.15587/2706-5448.2025.326047Keywords:

drying, consortium, chemical composition, hay, mechanical losses, alfalfa seeds, active ventilationAbstract

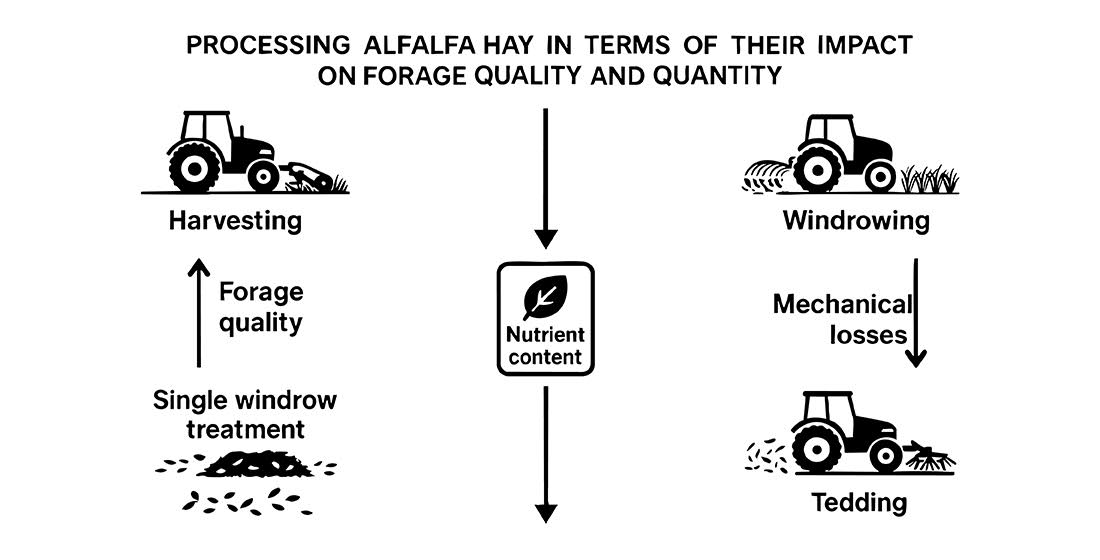

Haymaking is a key stage in feed production, as the choice of technological methods directly affects its quality, nutritional value, and digestibility by animals. One of the most significant challenges in this process is the mechanical loss of alfalfa leaves during harvesting and processing of the mown mass. It is well known that leaves contain the majority of protein, carotene, and other biologically active substances.

Research results have confirmed the significant impact of windrow processing frequency on dry matter losses and the nutritional value of the feed. It has been established that a single windrow treatment during drying reduces dry matter losses by 2.6–4.5 % compared to multiple tedding operations. This has a positive effect on the chemical composition of the hay and promotes the preservation of essential nutrients, particularly carotene. The carotene content in the natural mass with single windrow processing reached 32.4 mg/kg in the first experiment and 30.4 mg/kg in the second, which significantly exceeds the values for hay subjected to intensive mechanical processing.

Optimizing the haymaking process not only reduces nutrient losses but also shortens drying times, which is especially important under unfavorable weather conditions. Reducing the time that mown mass remains in the field minimizes the risk of feed quality deterioration due to precipitation and promotes uniform drying of stems and leaves.

Thus, improving the technological processes of alfalfa haymaking enables the production of high-quality feed with a high nutrient content and stable feed characteristics. Compared to traditional harvesting methods, the use of optimized technologies helps reduce dry matter losses, increase carotene and protein content, and improve the overall nutritional value of the hay. This contributes to a more efficient supply of high-quality roughage for livestock farming, which is a crucial factor in enhancing the productivity of agricultural animals and the profitability of the industry as a whole.

References

- Hryhoryuk, I. P., Boyko, O. A., Prylutska, S. V. (2014). Fiziolohiya roslyn z osnovamy biokhimiyi. Kyiv: Agrar Media Group LLC, 144.

- Hrushetskyi, S., Yaropud, V., Kupchuk, I., Semenyshena, R. (2021). The heap parts movement on the shareboard surface of the potato harvesting machine. Series II: Forestry Wood Industry Agricultural Food Engineering, 14 (63 (1)), 127–140. https://doi.org/10.31926/but.fwiafe.2021.14.63.1.12

- Kaletnik, G., Honcharuk, I., Yemchyk, T., Okhota, Y. (2020). The World Experience in the Regulation of the Land Circulation. European Journal of Sustainable Development, 9 (2), 557–568. https://doi.org/10.14207/ejsd.2020.v9n2p557

- Kovalevskyi, S. B. (2010). Intensyvnist osvitlennia v kulturakh sosny zvychainoi. Naukovyi visnyk NUBiP Ukrainy, 152, 227–234.

- Kupchuk, I. (2021). Multicriteria compromise optimization of feed grain grinding process. Przegląd Elektrotechniczny, 1 (11), 181–185. https://doi.org/10.15199/48.2021.11.33

- Kuznietsova, I., Bandura, V., Paziuk, V., Tokarchuk, O., Kupchuk, I. (2020). Application of the differential scanning calorimetry method in the study of the tomato fruits drying process. Agraarteadus. 31 (2), 173–180. https://doi.org/10.15159/jas.20.14

- Makarynska, S. A., Shlapak, V. P. (2010). Natural habitat of black pine (Pinusnigra Arn.) and it spread in the introduction. Naukovyi visnyk Natsionalnoho lisotekhnichnoho universytetu Ukrainy, 20.12, 39–45.

- Mazur, V., Didur, І., Tkachuk, О., Pantsyreva, H., Ovcharuk, V. (2021). Agroecological stability of cultivars of sparsely distributed legumes in the context of climate change. Scientific Horizons, 24 (1), 54–60. https://doi.org/10.48077/scihor.24(1).2021.54-60

- Mazur, V., Tkachuk, O., Pantsyreva, H., Kupchuk, I., Mordvaniuk, M., Chynchyk, O. (2021). Ecological suitability peas (Pisum sativum) varieties to climate change in Ukraine. Agraarteadus, 32 (2), 276–283. https://doi.org/10.15159/jas.21.26

- Mazur, V. A., Pantsyreva, H. V., Mazur, K. V., Didur, I. M. (2019). Influence of the assimilation apparatus and productivity of white lupine plants. Agronomy Research, 17 (1), 206–219. https://doi.org/10.15159/ar.19.024

- Mazur, V. A., Pantsyreva, H. V., Mazur, K. V., Myalkovsky, R. O., Alekseev, O. O. (2020). Agroecological prospects of using corn hybrids for biogas production. Agronomy Research, 18 (1), 177–182. https://doi.org/10.15159/ar.20.016

- Mytko, M. (2020). Determination of economic advisable distances of automobile delivery on autoservice enterprise. Engineering, Energy, Transport AIC, 1 (108), 58–64. https://doi.org/10.37128/2520-6168-2020-1-7

- Palamarchuk, V., Telekalo, N. (2018). The effect of seed size and seeding depth on the components of maize yield structure. Bulgarian Journal of Agricultural Science, 24 (5), 785–792.

- Poberezhets, Ju., Chudak, R., Kupchuk, I., Yaropud, V., Rutkevych, V. (2021). Effect of probiotic supplement on nutrient digestibility and production traits on broiler chicken. Agraarteadus, 32 (2), 296–302. https://doi.org/10.15159/jas.21.28

- Polievoda, Y., Kupchuk, I., Hontaruk, Y., Furman, I., Mytko, M. (2022). Method for determining homogeneity of fine dispersed mixtures based on the software analysis of photo cross-cut of the sample. Przegląd elektrotechniczny, 1 (11), 111–115. https://doi.org/10.15199/48.2022.11.20

- Puyu, V., Bakhmat, M., Khmelianchyshyn, Y., Stepanchenko, V., Bakhmat, O., Pantsyreva, H. (2021). Social-and-Ecological Aspects of Forage Production Reform in Ukraine in the Early 21st Century. European Journal of Sustainable Development, 10 (1), 221–228. https://doi.org/10.14207/ejsd.2021.v10n1p221

- Shlapak, V. P., Makarynska, S. A., Shlapak, V. V. (2011). Comparative characteristics of frost hardiness of some species of the genus Pinus L. Scientific Bulletin of the National Forestry University of Ukraine, 21.1, 18–22.

- Solomakha, N. H. (2009). Grafting of Pinus l. species to P. pallasiana D. Don in conditions of South-East of Ukraine. Forestry and agroforestry, 115, 71–74.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleksii Tokarchuk, Mykola Mytko, Serhii Burlaka, Igor Zozulyak, Mykola Stadnik

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.