Optimization of technological modes of cupola melting according to the criterion of maximum combustion temperature

DOI:

https://doi.org/10.15587/2706-5448.2025.328992Keywords:

cupola melting, cupola combustion temperature, air heating temperature, completeness of fuel combustionAbstract

The object of research is the combustion temperature in the cupola furnace. The problem under study was the complexity of predicting the temperature as a function of the control parameters of the melting.

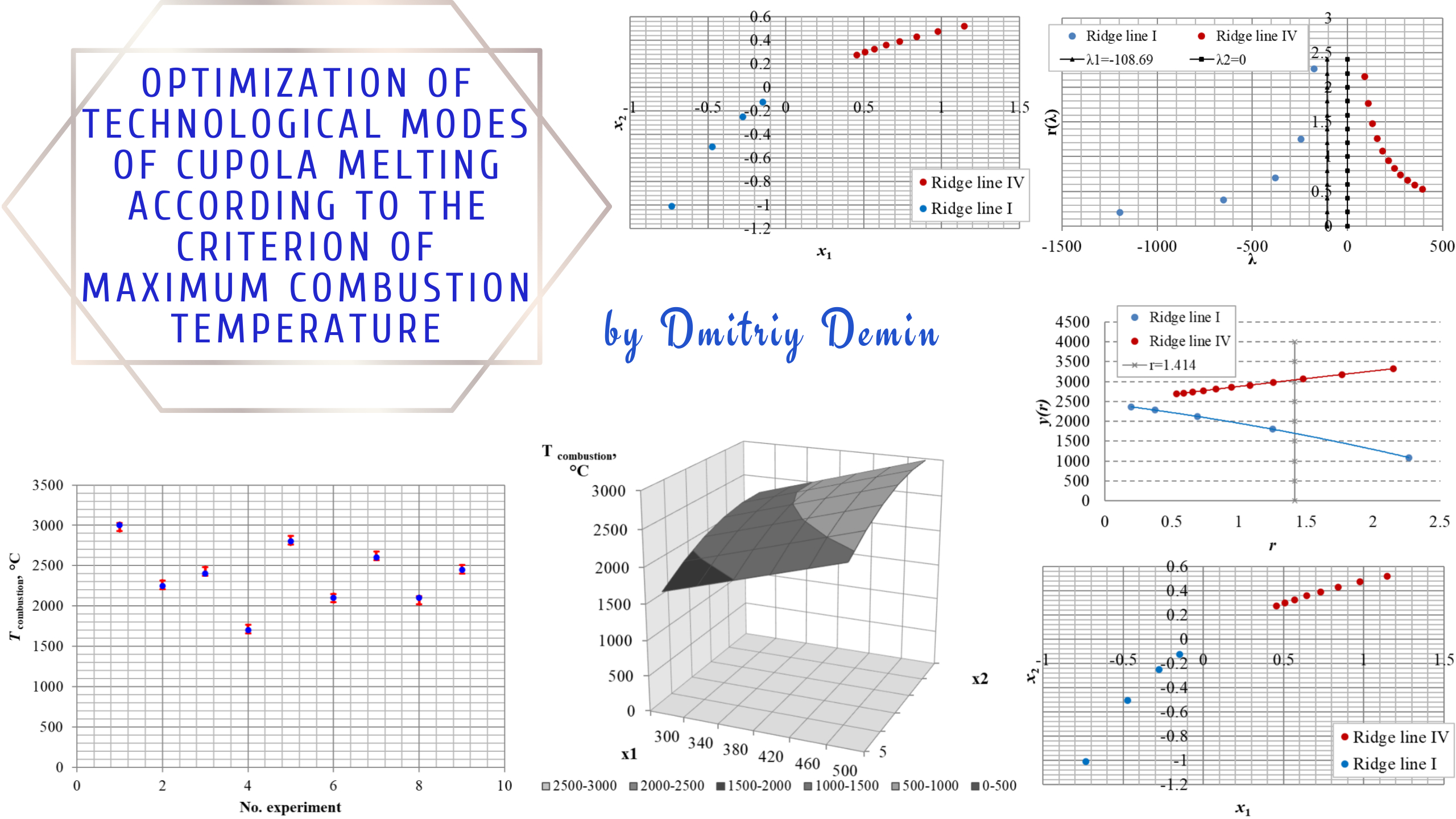

In the study, the control parameters were selected as the temperature of the air heating blown into the tuyeres and the completeness of fuel combustion. Using orthogonal experimental planning, a mathematical model was constructed in the form of a second-order polynomial, which allowed to identify the patterns of influence of each control factor on the resulting value – the combustion temperature.

The resulting mathematical model allowed to find out that both input variables are significant. However, if the nature of the influence of the air heating temperature on the combustion temperature is linear, then the completeness of combustion affects nonlinearly. The accuracy of the model turned out to be satisfactory, because all experimental data fell within the confidence intervals with a confidence probability of P=0.99. This allows to state the possibility of using the constructed model to predict the combustion temperature within the planning area.

The ridge analysis of the response surface established that the theoretical maximum value of the combustion temperature at the boundary of the planning area is about 3000 °C. This corresponds to the values of the input variables Tair≈1120 °C and η0≈82 %. However, due to the fact that ensuring the air heating temperature at the level of 1120 °C may encounter technical complexity of implementation, the following values of the input variables can be recommended: Tair=783–1060 °C, η0=71–80. They provide combustion temperatures in the range of 2690–2980 °C, i. e. values close to the suboptimal one determined by the ridge analysis.

These data allow making adjustments to the melting process, including being used for further searching for optimal melting control. The obtained solutions can be used in iron foundry shops of industrial enterprises equipped with cupola furnaces.

References

- Nwajagu, C. O., Ilochonwu, C. E. (2015). Understanding the Technology of Cupola Operation and Management Using Local Fabricated Cupola. NMS.

- Edward, K. (2008). Cupola Furnace – A Practical Treatise on the Construction and Management of Foundry Cupolas. Philadelphia.

- Olorunnishola, A. A. G., Anjorin, S. A. (2019). Development of a Statistical Model for the Effects of Air Blast Pressure, Melting Time and Fuel Consumed on Iron Melting Rate of an Erythrophleum Suave lens Charcoal-Fired Cupola Furnace. Journal of Physics: Conference Series, 1378 (4), 042026. https://doi.org/10.1088/1742-6596/1378/4/042026

- Abdelrahman, M., Kandasamy, P., Frolik, J. (2000). A methodology for the fusion of redundant sensors. Proceedings of the 2000 American Control Conference. ACC, 4, 2922–2926. https://doi.org/10.1109/acc.2000.878745

- Ochejah, Y. Y., Cyril, O., Omaone, I. F., Ogwudubi, A. F., Onakemu, O. A. (2021). Cupola Furnace Design and Fabrication for Industrial Development. International Journal of Scientific Advances, 2 (2), 102–106. https://doi.org/10.51542/ijscia.v2i2.3

- Stefanescu, D. M. (Ed.) (2017). Cast Iron Melting Furnaces. Cast Iron Science and Technology. ASM International, 121–145. https://doi.org/10.31399/asm.hb.v01a.a0006337

- PhaniShankar, C. V., Orth, S., Frolik, J., Abdelrahman, M. (2000). Fuzzy rules for automated sensor self-validation and confidence measure. Proceedings of the 2000 American Control Conference. ACC, 4, 2912–2916. https://doi.org/10.1109/acc.2000.878743

- Luis, C. J., Álvarez, L., Ugalde, M. J., Puertas, I. (2002). A technical note cupola efficiency improvement by increasing air blast temperature. Journal of Materials Processing Technology, 120 (1-3), 281–289. https://doi.org/10.1016/s0924-0136(01)01053-6

- O’Brien, W. A., Ohio, F. (1948). Pat. No. 2 443 960 USA. Control means for cupola furnaces. Serial No. 525,686 5 Claims (CI. 266–30). Available at: https://patents.google.com/patent/US2443960A/en

- Isnugroho, K., Birawidha, D. C. (2018). The production of pig iron from crushing plant waste using hot blast cupola. Alexandria Engineering Journal, 57 (1), 427–433. https://doi.org/10.1016/j.aej.2016.11.004

- Jezierski, J., Janerka, K. (2011). Selected Aspects of Metallurgical and Foundry Furnace Dust Utilization. Polish Journal of Environmental Studies, 20 (1), 101–105.

- Ristiana, R., Yunus, Ir. M. (2009). Temperature control of cupola melting. International Conference on Instrumentation, Communication, Information Technology, and Biomedical Engineering 2009, 1–5. https://doi.org/10.1109/icici-bme.2009.5417241

- Mahmoud, W. H., Abdelrahman, M., Haggard, R. L. (2004). Field programmable gate arrays implementation of automated sensor self-validation system for cupola furnaces. Computers & Industrial Engineering, 46 (3), 553–569. https://doi.org/10.1016/j.cie.2004.02.001

- Ristiana, R., Nurjaman, F., Yunus, M. (2013). Fuzzy Temperature Control for Melting Metals of Mini Cupola Furnaces. Research on Precision Instrument and Machinery, 2 (2), 30–35. Available at: https://www.academia.edu/27930776/Fuzzy_Temperature_Control_for_Melting_Metals_of_Mini_Cupola_Furnaces

- Lazzarin, R. M., Noro, M. (2015). Energy efficiency opportunities in the production process of cast iron foundries: An experience in Italy. Applied Thermal Engineering, 90, 509–520. https://doi.org/10.1016/j.applthermaleng.2015.07.028

- Demin, D., Frolova, L. (2024). Construction of a logical-probabilistic model of casting quality formation for managing technological operations in foundry production. EUREKA: Physics and Engineering, 6, 104–118. https://doi.org/10.21303/2461-4262.2024.003518

- Demin, D. (2023). Improving technology for manufacturing casting case of truck clutch release cylinder. ScienceRise, 2, 3–26. https://doi.org/10.21303/2313-8416.2023.003194

- Demin, D. (2019). Development of «whole» evaluation algorithm of the control quality of «cupola – mixer» melting duplex process. Technology Audit and Production Reserves, 3 (1 (47)), 4–24. https://doi.org/10.15587/2312-8372.2019.174449

- Demin, D. (2023). Experimental and industrial method of synthesis of optimal control of the temperature region of cupola melting. EUREKA: Physics and Engineering, 2, 68–82. https://doi.org/10.21303/2461-4262.2023.002804

- Demin, D. (2013). Adaptive modeling in problems of optimal control search termovremennoy cast iron. Eastern-European Journal of Enterprise Technologies, 6 (4 (66)), 31–37. https://doi.org/10.15587/1729-4061.2013.19453

- Demin, D., Domin, O. (2021). Adaptive technology for constructing the kinetic equations of reduction reactions under conditions of a priori uncertainty. EUREKA: Physics and Engineering, 4, 14–29. https://doi.org/10.21303/2461-4262.2021.001959

- Demin, D. (2014). Mathematical description typification in the problems of synthesis of optimal controller of foundry technological parameters. Eastern-European Journal of Enterprise Technologies, 1 (4 (67)), 43–56. https://doi.org/10.15587/1729-4061.2014.21203

- Nikolaiev, D. (2024). Construction of a cupola information profile for further modeling for the purpose of controlling melting processes. ScienceRise, 2, 3–14. https://doi.org/10.21303/2313-8416.2024.003674

- Nikolaiev, D., Selivorstov, V., Dotsenko, Y., Dzevochko, O., Pereverzieva, A., Dzevochko, A. (2025). Identification of temperature in cupola furnace based on the construction of the “slag composition – slag viscosity” model. Technology Audit and Production Reserves, 1 (1 (81)), 29–33. https://doi.org/10.15587/2706-5448.2025.322458

- Demin, D. (2020). Constructing the parametric failure function of the temperature control system of induction crucible furnaces. EUREKA: Physics and Engineering, 6, 19–32. https://doi.org/10.21303/2461-4262.2020.001489

- Stanovska, I., Duhanets, V., Prokopovych, L., Yakhin, S. (2021). Classification rule for determining the temperature regime of induction gray cast iron. EUREKA: Physics and Engineering, 1, 60–66. https://doi.org/10.21303/2461-4262.2021.001604

- Jopkiewicz, A., Podrzucki, C. (2007). Tendencies to the Improvement of the Cupola Process. Archives of foundry engineering, 13 (3), 61–70.

- Powell, W. L., Druschitz, A. P., Frost, J. (2008). Cupola Furnaces. Casting, 99–107. https://doi.org/10.31399/asm.hb.v15.a0005197

- Demin, D. (2025). Optimization of parameters of the cupola melting by the criterion of the maximum cast iron temperature. EUREKA: Physics and Engineering, 2, 158–165. https://doi.org/10.21303/2461-4262.2025.003712

- Demin, D. (2025). Determination of the heat-loaded zone of the cupola furnace and the level of the idle chargebased on the construction of an analytical description of the physical and chemical parameters of the melting. EUREKA: Physics and Engineering, 3, 00–00. https://doi.org/10.21303/2461-4262.2025.003771

- Larsen, E. D., Clark, D. E., Moore, K. L., King, P. E. (1997). Intelligent control of Cupola Melting. Available at: https://pdfs.semanticscholar.org/56c2/96af1d56d5cd963a5bcc38635142e5fa1968.pdf

- Domin, D., Lunin, D., Domina, O., Komyshan, A., Veski Saparali, K., Osadchyi, V.; Domin, D. (Ed.) (2022). The technology of scientific and practical communications: InGraph case study. Tallinn: Scientific Route OÜ, 184. https://doi.org/10.21303/978-9916-9516-9-9

- Domina, O. (2020). Selection of alternative solutions in the optimization problem of network diagrams of project implementation. Technology Audit and Production Reserves, 4 (4 (54)), 9–22. https://doi.org/10.15587/2706-5448.2020.210848

- Domina, O. (2020). Features of finding optimal solutions in network planning. EUREKA: Physics and Engineering, 6, 82–96. https://doi.org/10.21303/2461-4262.2020.001471

- Domina, O. (2021). Solution of the compromise optimization problem of network graphics on the criteria of uniform personnel loading and distribution of funds. Technology Audit and Production Reserves, 1 (4 (57)), 14–21. https://doi.org/10.15587/2706-5448.2021.225527

- Nieto-Delgado, C., Cannon, F. S., Paulsen, P. D., Furness, J. C., Voigt, R. C., Pagnotti, J. R. (2014). Bindered anthracite briquettes as fuel alternative to metallurgical coke: Full scale performance in cupola furnaces. Fuel, 121, 39–47. https://doi.org/10.1016/j.fuel.2013.12.034

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Dmitriy Demin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.