Determination of the influence of moisture of dehulled hemp seed kernels on storage quality indicators

DOI:

https://doi.org/10.15587/2706-5448.2025.329880Keywords:

industrial hemp, seeds, dehulling, kernels, storage, processing, humidity, mold, packaging, nutritional valueAbstract

The object of research is the regularities of the process of storing dehulled seeds of industrial hemp, seed moisture, storage packaging, structure of dehulled hemp kernels. The effect of the moisture content of the kernels of industrial hemp seeds of the “Glesia” variety on their storage period was studied. It was noted that hemp seeds are a source of easily digestible vegetable protein and contain a wide range of phytonutrients important for the health of cells, blood vessels and internal organs of a person. The kernels of industrial hemp seeds are a ready-to-use product.

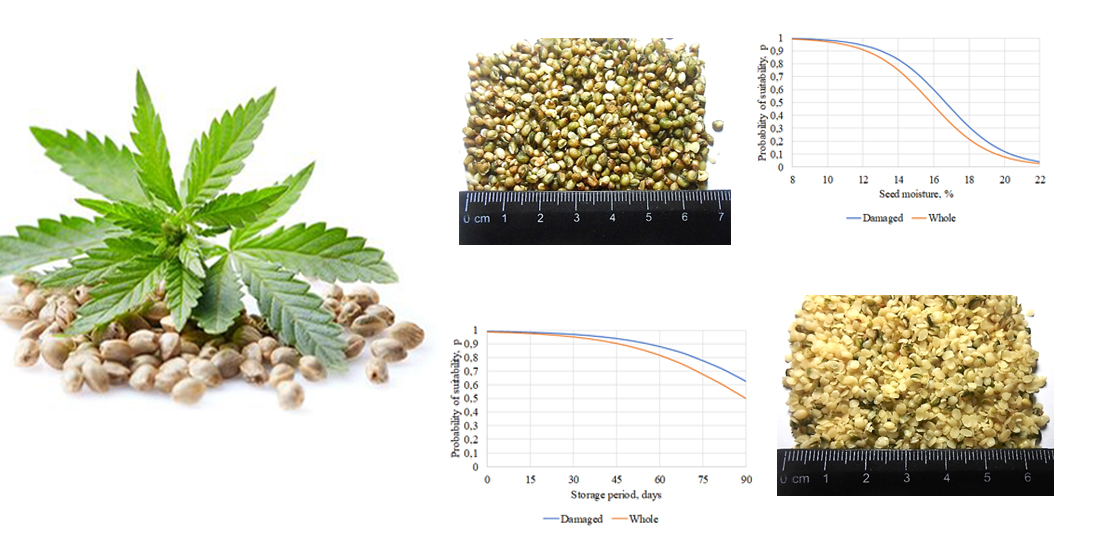

The shelling of seeds (separation of the shell from the kernel) was carried out mechanically by a centrifugal sheller of our own design. The diameter of the sheller impeller was 162 mm, the gap between the impeller and the reflecting deck was 80 mm, the impeller rotation speed was 2000 min-1.

The influence of humidity (21.6%, 16.3%, 12.0% and 8.8%) of hemp seeds on the storage period and quality indicators of kernels obtained from it was studied. Whole and crushed kernels without husks were stored in polyethylene bags without access of air from May to August under normal room conditions. It was found that kernels with a humidity of 21.6% became unusable after 15 days of storage due to the appearance of visible traces of mold. On the 30th day of storage, the mass in the bag turned into a white homogeneous mixture. It was noted that a whole kernel with increased humidity deteriorates faster compared to crushed ones. It was found that kernels with a seed humidity of 16.3% did not have visible signs of mold growth on the 15th day. However, mold was found in the bags on the 30th day of storage. In packages with whole kernels, it is more actively developed, and in packages with crushed kernels – insignificant traces. At seed moisture content of 12.0% and 8.8% after three months of storage, the packages with kernels remained unchanged. Visually, no visible signs of the appearance and reproduction of mold were found in these packages.

Logistic dependencies of the probability of kernel suitability for consumption have been established depending on seed moisture, storage duration, and kernel structure. The importance of controlling the initial seed moisture content to ensure the proper quality of the final product was noted.

References

- Yano, H., Fu, W. (2023). Hemp: A Sustainable Plant with High Industrial Value in Food Processing. Foods, 12 (3), 651. https://doi.org/10.3390/foods12030651

- Zelena knyha. Rynok tekhnichnykh konopel (2020). Avaialvle at: https://hempbud.com.ua/wp-content/uploads/rynok-tehnichnyh-konopel.pdf

- Farinon, B., Molinari, R., Costantini, L., Merendino, N. (2020). The Seed of Industrial Hemp (Cannabis sativa L.): Nutritional Quality and Potential Functionality for Human Health and Nutrition. Nutrients, 12 (7), 1935. https://doi.org/10.3390/nu12071935

- Sun, X., Sun, Y., Li, Y., Wu, Q., Wang, L. (2021). Identification and Characterization of the Seed Storage Proteins and Related Genes of Cannabis sativa L. Frontiers in Nutrition, 8. https://doi.org/10.3389/fnut.2021.678421

- Andronie, L., Pop, I. D., Sobolu, R., Diaconeasa, Z., Truţă, A., Hegeduş, C., Rotaru, A. (2021). Characterization of Flax and Hemp Using Spectrometric Methods. Applied Sciences, 11 (18), 8341. https://doi.org/10.3390/app11188341

- Alonso‐Esteban, J. I., González‐Fernández, M. J., Fabrikov, D., Torija‐Isasa, E., Sánchez‐Mata, M. de C., Guil‐Guerrero, J. L. (2020). Hemp (Cannabis sativa L.) Varieties: Fatty Acid Profiles and Upgrading of γ‐Linolenic Acid–Containing Hemp Seed Oils. European Journal of Lipid Science and Technology, 122 (7). https://doi.org/10.1002/ejlt.201900445

- Lan, Y., Zha, F., Peckrul, A., Hanson, B., Johnson, B., Rao, J., Chen, B. (2019). Genotype x Environmental Effects on Yielding Ability and Seed Chemical Composition of Industrial Hemp (Cannabis sativa L.) Varieties Grown in North Dakota, USA. Journal of the American Oil Chemists’ Society, 96 (12), 1417–1425. Portico. https://doi.org/10.1002/aocs.12291

- Golimowski, W., Teleszko, M., Marcinkowski, D., Kmiecik, D., Grygier, A., Kwaśnica, A. (2022). Quality of Oil Pressed from Hemp Seed Varieties: “Earlina 8FC”, “Secuieni Jubileu” and “Finola”. Molecules, 27 (10), 3171. https://doi.org/10.3390/molecules27103171

- Garcia, F. L., Ma, S., Dave, A., Acevedo-Fani, A. (2021). Structural and Physicochemical Characteristics of Oil Bodies from Hemp Seeds (Cannabis sativa L.). Foods, 10 (12), 2930. https://doi.org/10.3390/foods10122930

- Bárta, J., Roudnický, P., Jarošová, M., Zdráhal, Z., Stupková, A., Bártová, V. et al. (2023). Proteomic Profiles of Whole Seeds, Hulls, and Dehulled Seeds of Two Industrial Hemp (Cannabis sativa L.) Cultivars. Plants, 13 (1), 111. https://doi.org/10.3390/plants13010111

- Alonso-Esteban, J. I., Pinela, J., Ćirić, A., Calhelha, R. C., Soković, M., Ferreira, I. C. F. R. et al. (2022). Chemical composition and biological activities of whole and dehulled hemp (Cannabis sativa L.) seeds. Food Chemistry, 374, 131754. https://doi.org/10.1016/j.foodchem.2021.131754

- Alonso-Esteban, J. I., Torija-Isasa, M. E., Sánchez-Mata, M. de C. (2022). Mineral elements and related antinutrients, in whole and hulled hemp (Cannabis sativa L.) seeds. Journal of Food Composition and Analysis, 109, 104516. https://doi.org/10.1016/j.jfca.2022.104516

- Oseyko, M., Sova, N., Lutsenko, M., Kalyna, V. (2019). Chemical aspects of the composition of industrial hemp seed products. Ukrainian Food Journal, 8 (3), 544–559. https://doi.org/10.24263/2304-974x-2019-8-3-11

- Rahmawati, Aqil, M. (2020). The effect of temperature and humidity of storage on maize seed quality. IOP Conference Series: Earth and Environmental Science, 484, 012116. https://doi.org/10.1088/1755-1315/484/1/012116

- Oyekale, K. O., Daniel, I. O., Ajala, M. O., Sanni, L. O. (2012). Potential Longevity of Maize Seeds under Storage in Humid Tropical Seed Stores. Nature and Science, 10 (8), 114–124.

- Bareke, T., Addi, A., Roba, K., Kumsa, T. (2022). Effect of storage temperature and packing materials on seed germination and seed storage behavior of Schefflera abyssinica. Nusantara Bioscience, 14 (2). https://doi.org/10.13057/nusbiosci/n140202

- Huang, W., Zhong, Y., Meng, X., Song, X., Ren, M., Du, Y. (2021). Storage behaviour of Impatiens hainanensis seeds stored under three conditions. Seed Science and Technology, 49 (2), 175–186. https://doi.org/10.15258/sst.2021.49.2.08

- Hedimbi, M., Natalia, K., dan Martha Kandawa-Schulz, A. (2012). Effects of Storage Conditions on Viability, Germination and Sugar Content of Pearl Millet (Pennisetum glaucum) grains. Journal of Research in Agriculture, 1 (1), 88–92.

- Alemayehu, S., Abay, F., Ayimut, K. M., Assefa, D., Chala, A., Mahroof, R. et al. (2020). Evaluating different hermetic storage technologies to arrest mold growth, prevent mycotoxin accumulation and preserve germination quality of stored chickpea in Ethiopia. Journal of Stored Products Research, 85, 101526. https://doi.org/10.1016/j.jspr.2019.101526

- Oleksiienko, N., Obolkina, V., Syvnii, I. (2011). Mikrobiolohichna bezpeka kharchovykh produktiv. Prodovolcha industriia APK, 6 (14), 38–41.

- Pro zatverdzhennia Hihiienichnykh vymoh do vyrobnytstva ta obihu kharchovykh produktiv na potuzhnostiakh, roztashovanykh u zakladakh zahalnoi serednoi osvity (2020). Nakaz Ministerstva rozvytku ekonomiky, torhivli ta silskoho hospodarstva Ukrainy No. 2532. 03.12.2020. Avaialble at: https://ips.ligazakon.net/document/RE35558?an=2

- Sheichenko, V., Petrachenko, D., Koropchenko, S., Rogovskii, I., Gorbenko, O., Volianskyi, M., Sheichenko, D. (2024). Substantiating the rational parameters and operation modes for the hemp seed centrifugal dehuller. Eastern-European Journal of Enterprise Technologies, 2 (1 (128)), 34–48. https://doi.org/10.15587/1729-4061.2024.300174

- Sheichenko, V., Petrachenko, D., Rogovskii, I., Dudnikov, I., Shevchuk, V., Sheichenko, D. et al. (2024). Determining patterns in the separation of hemp seed hulls. Eastern-European Journal of Enterprise Technologies, 4 (1 (130)), 54–68. LOCKSS. https://doi.org/10.15587/1729-4061.2024.309869

- DSTU 4138-2002. Nasinnia silskohospodarskykh kultur. Metody vyznachennia yakosti (2004). Kyiv: Derzhspozhyvstandart Ukrainy, 157.

- Myhal, M. D., Kabantsia, V. M. (Eds.) (2011). Konopli. Sumy, 384.

- DSTU 7695:2015. Nasinnia konopel. Tekhnichni umovy (2015). Kyiv: DP “UkrNDNTs”, 8.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Viktor Sheichenko, Dmytro Petrachenko , Nataliia Sova, Vitaliy Shevchuk, Ihor Marynchenko, Oleh Prymakov, Denys Sheichenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.