Application of powdered Dutch cheese in wheat flour bread technology

DOI:

https://doi.org/10.15587/2706-5448.2025.331303Keywords:

wheat flour bread, powdered Dutch cheese, consumer properties, taste, nutritional valueAbstract

Bakery products made from wheat flour occupy a leading position in the assortment. Consumption of such products in the amount of the daily norm (277 g) allows to provide a person’s daily protein requirement by 40.0–43.0%. Wheat bread is a basic product in the diet of the majority of the population, therefore there is an objective need to expand its assortment with products with increased nutritional value, as well as to diversify its taste properties through the use of additional non-traditional raw materials.

The object of research is the technology of bread from wheat flour using powdered Dutch cheese to increase the nutritional value and consumer characteristics of the finished product.

It was established that powdered Dutch cheese is characterized by a good dissolution rate, low tendency to lump formation and a whiteness index corresponding to high-grade flour. The chemical composition of dry hard cheese is mainly represented by protein and fat, which will contribute to the enrichment of bakery products with milk proteins and milk fat.

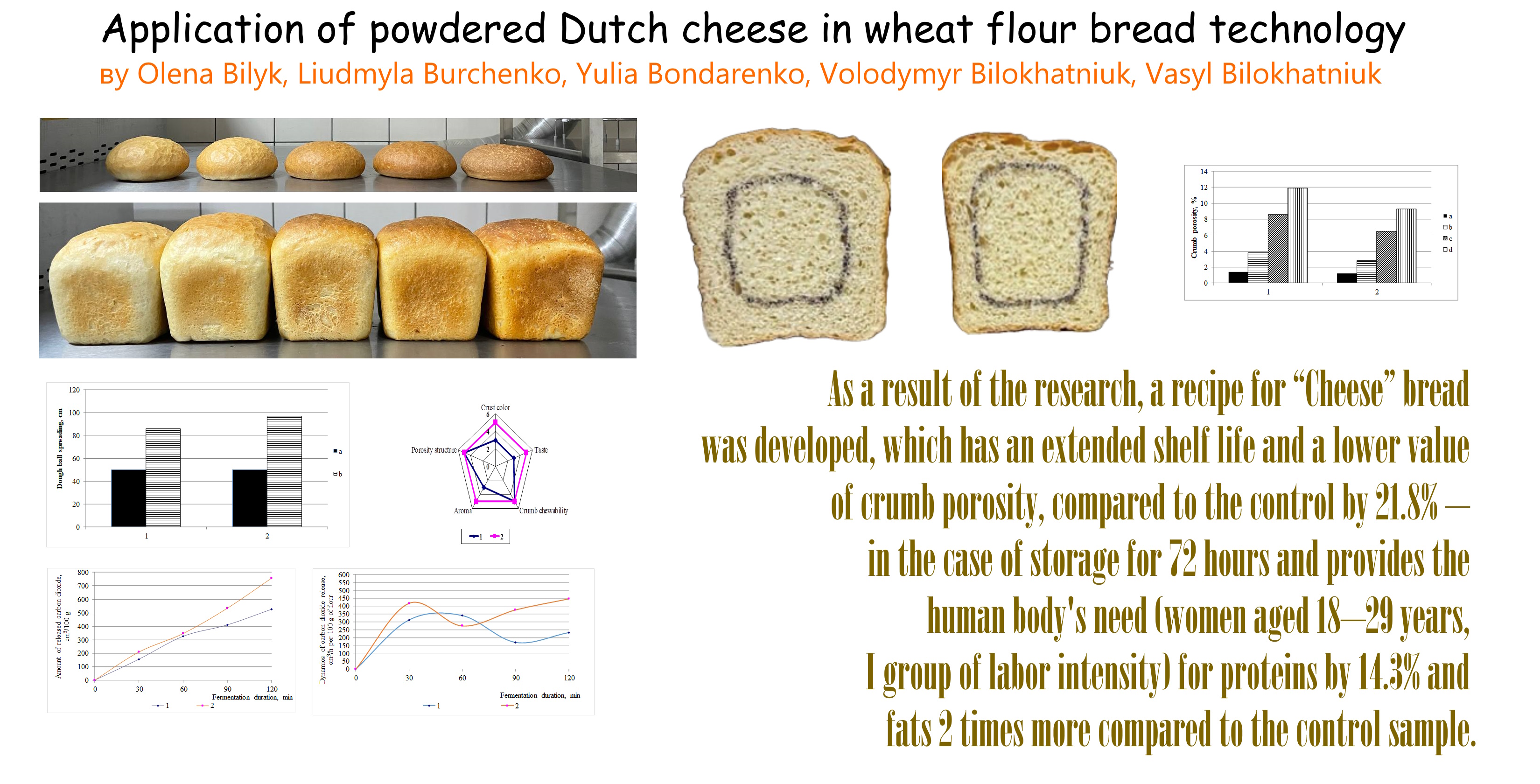

It was established that according to the complex quality indicator, the optimal dosage of powdered Dutch cheese in the recipe for wheat flour bread is 4.0% by weight of flour. At such a dosage, a bright color of the crust of the product and a lighter color of the crumb are noted compared to the control. The bread acquires a pleasant creamy taste and aroma.

It was established that in the case of dosing powdered Dutch cheese in an amount of 4.0% by weight of flour, the fermentation process is intensified, gluten is weakened, it becomes loose and a strong weakening of the dough is observed during proofing. This is the basis for reducing the duration of dough ripening.

As a result of the research, a recipe for “Cheese” bread was developed, which has an extended shelf life and a lower value of crumb porosity, compared to the control by 21.8% – in the case of storage for 72 hours and provides the human body's need (women aged 18–29 years, I group of labor intensity) for proteins by 14.3% and fats 2 times more compared to the control sample.

References

- Dong, Y., Karboune, S. (2021). A review of bread qualities and current strategies for bread bioprotection: Flavor, sensory, rheological, and textural attributes. Comprehensive Reviews in Food Science and Food Safety, 20 (2), 1937–1981. Portico. https://doi.org/10.1111/1541-4337.12717

- Younes, S. (2024). The impact of micronutrients on the sense of taste. Human Nutrition & Metabolism, 35, 200231. https://doi.org/10.1016/j.hnm.2023.200231

- Birch, A. N., Petersen, M. A., Hansen, Å. S. (2013). The aroma profile of wheat bread crumb influenced by yeast concentration and fermentation temperature. LWT – Food Science and Technology, 50 (2), 480–488. https://doi.org/10.1016/j.lwt.2012.08.019

- Graça, C., Raymundo, A., Sousa, I. de. (2021). Yoghurt and curd cheese addition to wheat bread dough: Impact on in vitro starch digestibility and estimated glycemic index. Food Chemistry, 339, 127887. https://doi.org/10.1016/j.foodchem.2020.127887

- Kochubei-Lytvynenko, O., Bilyk, O., Bondarenko, Yu., Stabnikov, V. (2022). Whey Proteins in Bakery Products. Bioenhancement and Fortification of Foods for a Healthy Diet. CRC Press is an imprint of Taylor & Francis Group, LLC, 67–88. https://doi.org/10.1201/9781003225287-5

- Amjad, A., Ullah, A., Javed, R., Khaliq, M., Ali, A., Raza, S. Q., Iqbal, S. (2023). Glycaemic index and glycaemic load of dairy based products, indigenous recipes and confectionery items of Pakistan. International Dairy Journal, 137, 105517. https://doi.org/10.1016/j.idairyj.2022.105517

- Drobot, V. I., Pysarets, O. P. (2014). Molochna syrovatka pokrashchuie yakist khliba z sumishi pshenychnoho i kukurudzianoho boroshna. Khranenye y pererabotka zerna, 10 (187), 46–48.

- Hnitsevych, V. A., Nykyforov, R. P., Fedotova, N. A., Kravchenko, N. V. (2014). Tekhnolohiia kharchovykh produktiv iz zadanymy vlastyvostiamy na osnovi vtorynnoi molochnoi ta roslynnoi syrovyny. Donetsk: DonNUET, 336.

- Iuga, M., Boestean, O., Ghendov-Mosanu, A., Mironeasa, S. (2020). Impact of Dairy Ingredients on Wheat Flour Dough Rheology and Bread Properties. Foods, 9 (6), 828. https://doi.org/10.3390/foods9060828

- Dobhal, A., Awasthi, P., Srivastava, S., Dutta, A., Shahi, N. C., Kumar, A. et al. (2024). Impact of liquid whey and barley flour fortification on the physicochemical, microbial, and sensory characteristics of buns stored in different packaging materials. Measurement: Food, 13, 100128. https://doi.org/10.1016/j.meafoo.2023.100128

- Smith, A. K., Campbell, B. E.; Tamine, A. Y. (Ed.) (2007). Microstructure of Milk Components. Structure of Dairy Products. Blackwell: Oxford, 59–71. https://doi.org/10.1002/9780470995921.ch3

- Yadav, J. S. S., Yan, S., Pilli, S., Kumar, L., Tyagi, R. D., Surampalli, R. Y. (2015). Cheese whey: A potential resource to transform into bioprotein, functional/nutritional proteins and bioactive peptides. Biotechnology Advances, 33 (6), 756–774. https://doi.org/10.1016/j.biotechadv.2015.07.002

- Karboviichuk, O. M., Kochubei-Lytvynenko, O. V., Cherniushok, O. A., Fedorov, V. H. (2012). Khimichnyi sklad i fizychni kharakterystyky molochnykh produktiv. Kyiv: NUKhT, 310.

- Hondar, O. P., Romanchuk, I. O. (2015). Changing of mineral composition dry demineralized whey at different processing methods. Zirnyk naukovykh prats Vinnytskoho natsionalnoho ahrarnoho un-tu, 1, 94–99.

- Ukrainets, A., Kochubei-Lytvynenko, O., Bilyk, O., Zakharevych, V., Vasylchenko, T. (2016). A study of the effect of enriched whey powder on the quality of a special-purpose bread. Eastern-European Journal of Enterprise Technologies, 2 (11 (80)), 32–41. https://doi.org/10.15587/1729-4061.2016.65778

- Minorova, I. O., Romanchuk, A. V., Krushelnytska, N. L., Matsko, L. M. (2015). The study of microstructure and surface-active properties of dry concentrate whey protein obtained by ultrafiltration. Zbirnyk naukovykh prats Vinnytskoho natsionalnoho ahrarnoho universytetu, 1 (2), 89–93.

- Lambert, J. L., Le‐Bail, A., Zuniga, R., Van‐Haesendonck, I., Vnzeveren, E., Petit, C. et al. (2009). The attitudes of European consumers toward innovation in bread; interest of the consumers toward selected quality attributes. Journal of Sensory Studies, 24 (2), 204–219. https://doi.org/10.1111/j.1745-459x.2008.00203.x

- Turk-Gul, A., Urgu-Ozturk, M., Koca, N. (2023). The effects of different amounts of maltodextrin on the rheological behaviour and stability of white cheese emulsions, and the physical, microstructural, chemical and sensory properties of white cheese powders. International Dairy Journal, 138, 105552. https://doi.org/10.1016/j.idairyj.2022.105552

- Ali, B., Khan, K. Y., Majeed, H., Jin, Y., Xu, D., Rao, Z., Xu, X. (2022). Impact of Soy-Cow’s mixed milk enzyme modified cheese on bread aroma. LWT, 154, 112793. https://doi.org/10.1016/j.lwt.2021.112793

- Drobot, V. I. (2019). Dovidnyk z tekhnolohii khlibopekarskoho vyrobnytstva. Kyiv: profKnyha, 580.

- Lebedenko, T. Ie., Pshenyshniuk, H. F., Sokolova, N. Iu. (2014) Tekhnolohiia khlibopekarskoho vyrobnytstva. Praktykum. Odesa: Osvita Ukrainy, 392.

- Drobot, V. I. (Ed.) (2015). Tekhnokhimichnyi kontrol syrovyny ta khlibobulochnykh i makaronnykh vyrobiv. Kyiv: NUKhT, 902.

- Makhynko, R. (2021). The upgraded dough running measurement device. Scientific Look into the Future, 1 (19-01), 28–31. https://doi.org/10.30888/2415-7538.2020-19-01-025

- Bilyk, О., Bondarenko, Y. (2024). Methods of determining the freshness of bakery products using the example of the influence of an improvement on the freshness of bran bread. Innovative scientific research. Toronto, 104–107. https://doi.org/10.5281/zenodo.12548671

- Bilyk, O., Bogachov, I., Bondarenko, Y., Fain, A., Bilokhatniuk, V. (2025). Using reheating of baked products to prolong their freshness. Technology Audit and Production Reserves, 1 (3 (81)), 39–44. https://doi.org/10.15587/2706-5448.2025.323829

- Coelho, M. S., Salas-Mellado, M. de las M. (2015). Effects of substituting chia (Salvia hispanica L.) flour or seeds for wheat flour on the quality of the bread. LWT – Food Science and Technology, 60 (2), 729–736. https://doi.org/10.1016/j.lwt.2014.10.033

- Dessev, T., Lalanne, V., Keramat, J., Jury, V., Prost, C., Le-Bail, A. (2020). Influence of Baking Conditions on Bread Characteristics and Acrylamide Concentration. Journal of Food Science and Nutrition Research, 3 (4), 291–310. https://doi.org/10.26502/jfsnr.2642-11000056

- Drobot, V. I., Yurchak, V. H., Arsenieva, L. Yu. et al.; Drobot, V. I. (Ed.) (2016). Praktykum z tekhnolohichnykh rozrakhunkiv u khlibopekarskomu vyrobnytstvi. Kyiv: Kondor, 330.

- Kaan, I., Tuna, O., Tepe, A., Ergin Zeren, F., Küçükçetin, A. (2024). Effect of drying temperatures and using prebiotics on the physicochemical and microbiological properties as well as consumer acceptance of probiotic-enriched Lor cheese snacks produced by vacuum drying. International Journal of Gastronomy and Food Science, 36, 100929. https://doi.org/10.1016/j.ijgfs.2024.100929

- Jusoh, Y. M., Chin, N. L., Yusof, Y. A., Rahman, R. A. (2008). Bread crust thickness estimation using LAB colour system. Pertanika Journal of Science & Technology, 16 (2), 239–247.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Olena Bilyk, Liudmyla Burchenko, Yulia Bondarenko, Volodymyr Bilokhatniuk, Vasyl Bilokhatniuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.