Determination of optimal operating modes of the selective catalytic reduction system for marine diesel exhaust gases

DOI:

https://doi.org/10.15587/2706-5448.2025.340411Keywords:

environmental indicators, maritime transport, exhaust gas purification, marine diesel, catalytic reduction systemAbstract

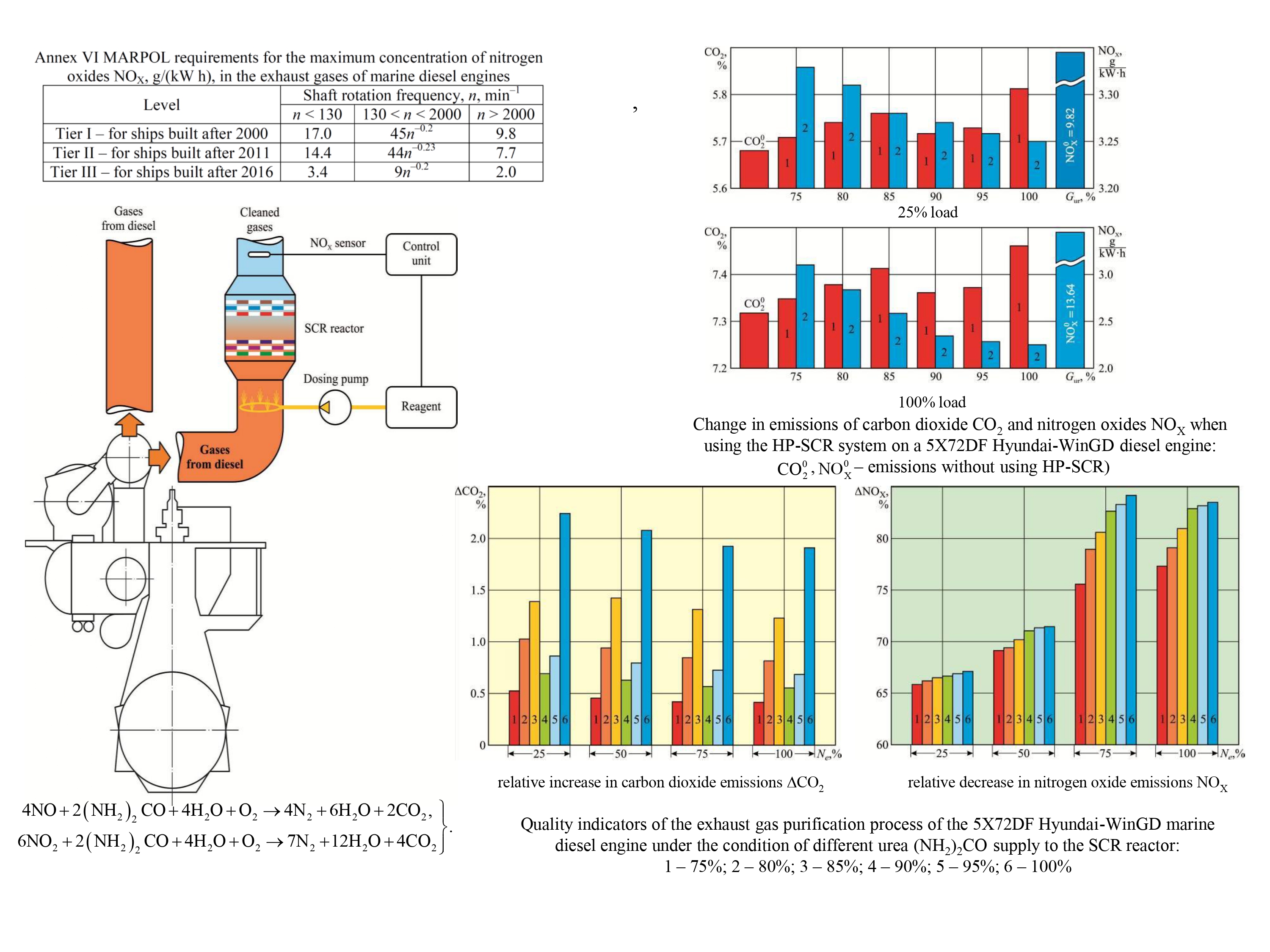

The object of research is the process of ensuring the minimum level of carbon dioxide emissions when using selective catalytic reduction of exhaust gases from nitrogen oxides. It is noted that catalytic reduction systems provide the most effective purification of exhaust gases from nitrogen oxides. At the same time, due to the use of urea as a reagent in these systems, carbon dioxide emissions increase. This increases the greenhouse effect and reduces the energy efficiency of the ship. The research results presented in the work were carried out on a Gas Carrier class ship with a displacement of 127,645 tons with two main engines 5X72DF Hyundai-WinGD and three auxiliary engines 6H35DF Hyundai-HiMSEN. 5X72DF Hyundai-WinGD diesel engines were equipped with a high-pressure catalytic reduction system, 6H35DF Hyundai-HiMSEN diesel engines – with a low-pressure catalytic reduction system. It has been experimentally established that within the recommended range of urea supply to the catalytic reduction system of exhaust gases, there are optimal modes that ensure a minimal increase in carbon dioxide emissions while maintaining a high level of reduction in nitrogen oxide emissions. In these modes, the relative increase in carbon dioxide emissions does not exceed 2.3% for both types of diesel engines. Nitrogen oxide emissions for 5X72DF Hyundai-WinGD diesel engines do not exceed 3.3 g/(kW h) and do not exceed 2.4 g/(kW h) for 6H35DF Hyundai-HiMSEN diesel engines, which meets the requirements of Annex VI MARPOL. The relative reduction in nitrogen oxide emissions in these modes is 66.7–83.4% for 5X72DF Hyundai-WinGD diesel engines and 60.8–78.3% for 6H35DF Hyundai-HiMSEN diesel engines. The coincidence of the obtained values for the low-speed diesel engine 5X72DF Hyundai-WinGD and the medium-speed 6H35DF Hyundai-HiMSEN indicates the correctness of the research and the possibility of implementing their results on all types of diesel engines and catalytic reduction systems.

References

- Kolegaev, M., Brazhnik, I. (2024). Improvement of the process of preparing cargo tanks of crude oil tankers for cargo operations. Technology Audit and Production Reserves, 6 (1 (80)), 36–40. https://doi.org/10.15587/2706-5448.2024.318534

- Matieiko, O. (2024). Selection of optimal schemes for the inerting process of cargo tanks of gas carriers. Technology Audit and Production Reserves, 4 (1 (78)), 43–50. https://doi.org/10.15587/2706-5448.2024.310699

- Maryanov, D. (2021). Development of a method for maintaining the performance of drilling fluids during transportation by Platform Supply Vessel. Technology Audit and Production Reserves, 5 (2 (61)), 15–20. https://doi.org/10.15587/2706-5448.2021.239437

- Maryanov, D. (2022). Reduced energy losses during transportation of drilling fluid by Platform Supply Vessels. Technology Audit and Production Reserves, 2 (1 (64)), 42–50. https://doi.org/10.15587/2706-5448.2022.256473

- Fomin, O., Lovska, A., Kučera, P., Píštěk, V. (2021). Substantiation of Improvements for the Bearing Structure of an Open Car to Provide a Higher Security during Rail/Sea Transportation. Journal of Marine Science and Engineering, 9 (8), 873. https://doi.org/10.3390/jmse9080873

- Vladov, S., Shmelov, Y., Yakovliev, R. (2022). Optimization of Helicopters Aircraft Engine Working Process Using Neural Networks Technologies. CEUR Workshop Proceedings, 3171, 1639–1656. Available at: https://ceur-ws.org/Vol-3171/paper117.pdf

- Madey, V. (2022). Assessment of the efficiency of biofuel use in the operation of marine diesel engines. Technology Audit and Production Reserves, 2 (1 (64)), 34–41. https://doi.org/10.15587/2706-5448.2022.255959

- Budashko, V., Sandler, A., Shevchenko, V. (2022). Diagnosis of the Technical Condition of High-tech Complexes by Probabilistic Methods. TransNav, the International Journal on Marine Navigation and Safety of Sea Transportation, 16 (1), 105–111. https://doi.org/10.12716/1001.16.01.11

- Sagin, S., Sagin, A., Zablotskyi, Y., Fomin, O., Píštěk, V., Kučera, P. (2025). Method for Maintaining Technical Condition of Marine Diesel Engine Bearings. Lubricants, 13 (4), 146. https://doi.org/10.3390/lubricants13040146

- Sagin, S., Haichenia, O., Karianskyi, S., Kuropyatnyk, O., Razinkin, R., Sagin, A. et al. (2025). Improving Green Shipping by Using Alternative Fuels in Ship Diesel Engines. Journal of Marine Science and Engineering, 13 (3), 589. https://doi.org/10.3390/jmse13030589

- Sagin, S. V., Kuropyatnyk, O. A., Zablotskyi, Y. V., Gaichenia, O. V. (2022). Supplying of Marine Diesel Engine Ecological Parameters. Naše More, 69 (1), 53–61. https://doi.org/10.17818/nm/2022/1.7

- Khlopenko, M., Gritsuk, I., Sharko, O., Appazov, E. (2024). Increasing the accuracy of the vessel’s course orientation. Technology Audit and Production Reserves, 1 (2 (75)), 25–30. https://doi.org/10.15587/2706-5448.2024.298518

- Budashko, V., Shevchenko, V. (2021). Solving a task of coordinated control over a ship automated electric power system under a changing load. Eastern-European Journal of Enterprise Technologies, 2 (2 (110)), 54–70. https://doi.org/10.15587/1729-4061.2021.229033

- Ma, Z., Du, T., Duan, S., Qu, H., Wang, K., Xing, H. et al. (2023). Analysis of Exhaust Pollutants from Four-Stroke Marine Diesel Engines Based on Bench Tests. Journal of Marine Science and Engineering, 11 (2), 413. https://doi.org/10.3390/jmse11020413

- Wang, F., Zhao, J., Li, T., Guan, P., Liu, S., Wei, H. et al. (2025). Research on NOx Emissions Testing and Optimization Strategies for Diesel Engines Under Low-Load Cycles. Atmosphere, 16 (2), 190. https://doi.org/10.3390/atmos16020190

- Wang, Z., Ma, Q., Zhang, Z., Li, Z., Qin, C., Chen, J. et al. (2023). A Study on Monitoring and Supervision of Ship Nitrogen-Oxide Emissions and Fuel-Sulfur-Content Compliance. Atmosphere, 14 (1), 175. https://doi.org/10.3390/atmos14010175

- Sagin, S., Sagin, A. (2023). Development of method for managing risk factors for emergency situations when using low-sulfur content fuel in marine diesel engines. Technology Audit and Production Reserves, 5 (1 (73)), 37–43. https://doi.org/10.15587/2706-5448.2023.290198

- Kong, K.-J., Hwang, S.-C. (2024). Development and Performance Evaluation Experiment of a Device for Simultaneous Reduction of SOx and PM. Energies, 17 (13), 3337. https://doi.org/10.3390/en17133337

- Golovan, A., Gritsuk, I., Honcharuk, I. (2024). Reliable Ship Emergency Power Source: A Monte Carlo Simulation Approach to Optimize Remaining Capacity Measurement Frequency for Lead-Acid Battery Maintenance. SAE International Journal of Electrified Vehicles, 13 (2), 179–189. https://doi.org/10.4271/14-13-02-0009

- Melnyk, O., Fomin, O., Shumylo, O., Yarovenko, V., Jurkovič, M., Ocheretna, V.; Babak, V., Zaporozhets, A. (Eds.) (2025). Simulation of the Interrelationship Between Energy Efficiency and Ship Safety Based on Empirical Data and Regression Analysis. Systems, Decision and Control in Energy VII. Cham: Springer, 277–293. https://doi.org/10.1007/978-3-031-90462-2_16

- Sagin, S., Kuropyatnyk, O., Matieiko, O., Razinkin, R., Stoliaryk, T., Volkov, O. (2024). Ensuring Operational Performance and Environmental Sustainability of Marine Diesel Engines through the Use of Biodiesel Fuel. Journal of Marine Science and Engineering, 12 (8), 1440. https://doi.org/10.3390/jmse12081440

- Sagin, S. V., Karianskyi, S., Sagin, S. S., Volkov, O., Zablotskyi, Y., Fomin, O. et al. (2023). Ensuring the safety of maritime transportation of drilling fluids by platform supply-class vessel. Applied Ocean Research, 140, 103745. https://doi.org/10.1016/j.apor.2023.103745

- Sagin, S. V., Kuropyatnyk, O. A. (2018). The Use of Exhaust Gas Recirculation for Ensuring the Environmental Performance of Marine Diesel Engines. Naše More, 65 (2), 78–86. https://doi.org/10.17818/nm/2018/2.3

- International Convention for the Prevention of Pollution from Ships (MARPOL). International Maritime Organization. Available at: https://www.imo.org/en/about/Conventions/Pages/International-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx Last accessed: 23.09.2025

- Varbanets, R., Fomin, O., Píštěk, V., Klymenko, V., Minchev, D., Khrulev, A. et al. (2021). Acoustic Method for Estimation of Marine Low-Speed Engine Turbocharger Parameters. Journal of Marine Science and Engineering, 9 (3), 321. https://doi.org/10.3390/jmse9030321

- Vladov, S., Shmelov, Y., Yakovliev, R., Stushchankyi, Y., Havryliuk, Y. (2023). Neural Network Method for Controlling the Heli-copters Turboshaft Engines Free Turbine Speed at Flight Modes. CEUR Workshop Proceedings, 3426, 89–108. Available at: https://ceur-ws.org/Vol-3426/paper8.pdf

- Zhevzhyk, O., Potapchuk, I., Horiachkin, V., Raksha, S., Bosyi, D., Reznyk, A. (2025). Mathematical modelling of mixture formation in the combustion chamber of a diesel engine. Technology Audit and Production Reserves, 2 (1 (82)), 63–68. https://doi.org/10.15587/2706-5448.2025.326746

- Wang, W., Wang, G., Wang, Z., Lei, J., Huang, J., Nie, X. et al. (2022). Optimization of Miller Cycle, EGR, and VNT on Performance and NOx Emission of a Diesel Engine for Range Extender at High Altitude. Energies, 15 (23), 8817. https://doi.org/10.3390/en15238817

- Lee, J.-U., Hwang, S.-C., Han, S.-H. (2023). Numerical and Experimental Study on NOx Reduction According to the Load in the SCR System of a Marine Boiler. Journal of Marine Science and Engineering, 11 (4), 777. https://doi.org/10.3390/jmse11040777

- Fischer, D., Vith, W., Unger, J. L. (2024). Assessing Particulate Emissions of Novel Synthetic Fuels and Fossil Fuels under Different Operating Conditions of a Marine Engine and the Impact of a Closed-Loop Scrubber. Journal of Marine Science and Engineering, 12 (7), 1144. https://doi.org/10.3390/jmse12071144

- Wang, W., Li, Z., Ji, X., Wang, Y., Wang, X. (2024). Water Injection for Cloud Cavitation Suppression: Analysis of the Effects of Injection Parameters. Journal of Marine Science and Engineering, 12 (8), 1277. https://doi.org/10.3390/jmse12081277

- Amoresano, A., Langella, G., Iodice, P., Roscioli, S. (2023). Numerical Analysis of SO2 Absorption inside a Single Water Drop. Atmosphere, 14 (12), 1746. https://doi.org/10.3390/atmos14121746

- Ershov, M. A., Grigorieva, E. V., Abdellatief, T. M. M., Kapustin, V. M., Abdelkareem, M. A., Kamil, M. et al. (2021). Hybrid low-carbon high-octane oxygenated gasoline based on low-octane hydrocarbon fractions. Science of The Total Environment, 756, 142715. https://doi.org/10.1016/j.scitotenv.2020.142715

- Petrychenko, O., Levinskyi, M., Prytula, D., Vynohradova, A. (2023). Fuel options for the future: a comparative overview of properties and prospects. Transport Systems and Technologies, 41, 96–106. https://doi.org/10.32703/2617-9059-2023-41-8

- Zannis, T. C., Katsanis, J. S., Christopoulos, G. P., Yfantis, E. A., Papagiannakis, R. G., Pariotis, E. G. et al. (2022). Marine Exhaust Gas Treatment Systems for Compliance with the IMO 2020 Global Sulfur Cap and Tier III NOx Limits: A Review. Energies, 15 (10), 3638. https://doi.org/10.3390/en15103638

- Lee, T., Cho, J., Lee, J. (2022). Mixing Properties of Emulsified Fuel Oil from Mixing Marine Bunker-C Fuel Oil and Water. Journal of Marine Science and Engineering, 10 (11), 1610. https://doi.org/10.3390/jmse10111610

- Melnyk, O., Onishchenko, O., Onyshchenko, S., Voloshyn, A., Ocheretna, V.; Zaporozhets, A. (Ed.) (2023). Comprehensive Study and Evaluation of Ship Energy Efficiency and Environmental Safety Management Measures. Systems, Decision and Control in Energy V. Studies in Systems, Decision and Control. Cham: Springer, 481. https://doi.org/10.1007/978-3-031-35088-7_38

- Nelyubov, D. V., Fakhrutdinov, M. I., Sarkisyan, A. A., Sharin, E. A., Ershov, M. A., Makhova, U. A. et al. (2023). New Prospects of Waste Involvement in Marine Fuel Oil: Evolution of Composition and Requirements for Fuel with Sulfur Content up to 0.5%. Journal of Marine Science and Engineering, 11 (7), 1460. https://doi.org/10.3390/jmse11071460

- Senčić, T., Mrzljak, V., Blecich, P., Bonefačić, I. (2019). 2D CFD Simulation of Water Injection Strategies in a Large Marine Engine. Journal of Marine Science and Engineering, 7 (9), 296. https://doi.org/10.3390/jmse7090296

- Pelić, V., Mrakovčić, T., Medica-Viola, V., Valčić, M. (2020). Effect of Early Closing of the Inlet Valve on Fuel Consumption and Temperature in a Medium Speed Marine Diesel Engine Cylinder. Journal of Marine Science and Engineering, 8 (10), 747. https://doi.org/10.3390/jmse8100747

- Kuropyatnyk, O. A., Sagin, S. V. (2019). Exhaust Gas Recirculation as a Major Technique Designed to Reduce NOх Emissions from Marine Diesel Engines. Naše More, 66 (1), 1–9. https://doi.org/10.17818/nm/2019/1.1

- Ruban, D., Krainyk, L., Ruban, H., Shevchuk, V., Artyukh, O., Mahats, M. et al. (2025). Estimation of fuel consumption in standard driving cycles and in real bus operation. Technology Audit and Production Reserves, 2 (1 (82)), 50–56. https://doi.org/10.15587/2706-5448.2025.326476

- Kučera, O., Píštěk, V., Fomin, O., Kučera, P., Sagin, S. (2025). Measuring Device for More Precise Mistuning Identification of Integrated Bladed Discs. Symmetry, 17 (5), 717. https://doi.org/10.3390/sym17050717

- Lamas Galdo, M. I., Castro-Santos, L., Rodriguez Vidal, C. G. (2020). Numerical Analysis of NOx Reduction Using Ammonia Injection and Comparison with Water Injection. Journal of Marine Science and Engineering, 8 (2), 109. https://doi.org/10.3390/jmse8020109

- Drazdauskas, M., Lebedevas, S. (2024). Numerical Study on Optimization of Combustion Cycle Parameters and Exhaust Gas Emissions in Marine Dual-Fuel Engines by Adjusting Ammonia Injection Phases. Journal of Marine Science and Engineering, 12 (8), 1340. https://doi.org/10.3390/jmse12081340

- Petrenko, T. (2025). Study of physicochemical and geochemical aspects of enhanced oil recovery and CO₂ storage in oil reservoirs. Technology Audit and Production Reserves, 2 (1 (82)), 24–29. https://doi.org/10.15587/2706-5448.2025.325343

- Bian, J., Duan, L., Yang, Y. (2023). Simulation and Economic Investigation of CO2 Separation from Gas Turbine Exhaust Gas by Molten Carbonate Fuel Cell with Exhaust Gas Recirculation and Selective Exhaust Gas Recirculation. Energies, 16 (8), 3511. https://doi.org/10.3390/en16083511

- Sagin, S., Kuropyatnyk, O., Rusnak, D. (2025). Improvement of the process of cleaning exhaust gases of marine diesels from sulfur oxides. Technology Audit and Production Reserves, 4 (1 (84), 72–79. https://doi.org/10.15587/2706-5448.2025.337616

- Sagin, S. V., Solodovnikov, V. G. (2017). Estimation of Operational Properties of Lubricant Coolant Liquids by Optical Methods. International Journal of Applied Engineering Research, 12 (19), 8380–8391. Available at: https://www.ripublication.com/ijaer17/ijaerv12n19_51.pdf

- Sagin, S. V., Semenov, O. V. (2016). Motor Oil Viscosity Stratification in Friction Units of Marine Diesel Motors. American Journal of Applied Sciences, 13 (2), 200–208. https://doi.org/10.3844/ajassp.2016.200.208

- Zablotsky, Y. V., Sagin, S. V. (2016). Maintaining Boundary and Hydrodynamic Lubrication Modes in Operating High-pressure Fuel Injection Pumps of Marine Diesel Engines. Indian Journal of Science and Technology, 9 (20). https://doi.org/10.17485/ijst/2016/v9i20/94490

- Zablotsky, Y. V., Sagin, S. V. (2016). Enhancing Fuel Efficiency and Environmental Specifications of a Marine Diesel When using Fuel Additives. Indian Journal of Science and Technology, 9 (46). https://doi.org/10.17485/ijst/2016/v9i46/107516

- Li, M., Qiu, M., Li, Y., Tang, H., Wu, R., Yu, Z. et al. (2025). Research on Ship Carbon-Emission Monitoring Technology and Suggestions on Low-Carbon Shipping Supervision System. Atmosphere, 16 (7), 773. https://doi.org/10.3390/atmos16070773

- Petrychenko, O., Levinskyi, M., Goolak, S., Lukoševičius, V. (2025). Prospects of Solar Energy in the Context of Greening Maritime Transport. Sustainability, 17 (5), 2141. https://doi.org/10.3390/su17052141

- Goolak, S., Riabov, I., Petrychenko, O., Kyrychenko, M., Pohosov, O. (2025). The simulation model of an induction motor with consideration of instantaneous magnetic losses in steel. Advances in Mechanical Engineering, 17 (2). https://doi.org/10.1177/16878132251320236

- Kyaw Oo D’Amore, G., Biot, M., Mauro, F., Kašpar, J. (2021). Green Shipping–Multifunctional Marine Scrubbers for Emission Control: Silencing Effect. Applied Sciences, 11 (19), 9079. https://doi.org/10.3390/app11199079

- Kim, D., Lee, C. (2019). SCR Performance Evaluations in Relation to Experimental Parameters in a Marine Generator Engine. Journal of Marine Science and Engineering, 7 (3), 67. https://doi.org/10.3390/jmse7030067

- Kravchenko, O., Symonenko, R., Gerlici, J., Golovan, A., Shymanskyi, S., Gritsuk, I. et al. (2025). Research on the Use of Biogas as an Additive to Compressed Natural Gas for Supplying Vehicle Engines. Communications – Scientific Letters of the University of Zilina, 27 (3), 158–169. https://doi.org/10.26552/com.c.2025.034

- Stoliaryk, T. (2022). Analysis of the operation of marine diesel engines when using engine oils with different structural characteristics. Technology Audit and Production Reserves, 5 (1 (67)), 22–32. https://doi.org/10.15587/2706-5448.2022.265868

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Sergii Sagin, Oleksiy Kuropyatnyk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.