Identification of patterns in sugar beet storage conditions depending on enzymatic activity

DOI:

https://doi.org/10.15587/2706-5448.2025.341492Keywords:

sugar beet, storage, sulfur dioxide, enzymes, oxidoreductases, hydrolases, quality indicatorsAbstract

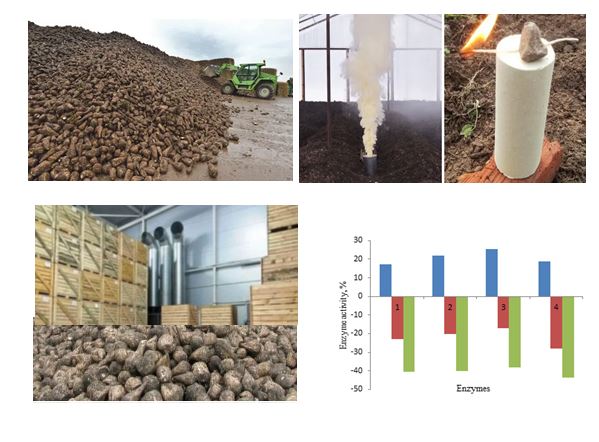

The object of the research is the storage conditions of sugar beets (Beta vulgaris). One of the most challenging areas is the reduction in sucrose content during storage under normal conditions prior to processing. The study focused on storing sugar beets in a refrigerated chamber to preserve the quality of the raw material, slow down respiration processes, minimize sugar loss, and extend shelf life. This allows for the use of sugar beets not only during the mass harvest but also over a long period, ensuring a uniform plant load and creating a reserve of environmentally friendly and technologically suitable raw materials for the stable operation of sugar production during the off-season.

The study utilized various methods of storing sugar beets in a refrigerated chamber, including storage at temperatures of +2 to +3°C and at a relative humidity of 85–95%. The study also employed the same storage conditions but with the use of sulfur dioxide. It was found that when stored in a refrigerated chamber with sulfur dioxide fumigation every ten days, sucrose content decreased by 2.6%. After 90 days, a decrease of 5.9% and 3.3%, respectively, was recorded, and on the last day of storage, i. e., after 120 days, a decrease of 7.2% and 3.9% was recorded. This is due to the fact that the use of sulfur dioxide inhibits the activity of oxidoreductases and hydrolases, which reduces the consumption of sucrose and other nutrients in the respiration process. This increases the shelf life of sugar beets and allows them to be used not only during the mass harvest but also over a long period, ensuring a uniform plant load. Under these conditions, the content of sucrose and other nutrients decreases slightly, and the yield of granulated sugar increases. Compared to similar known sugar beet storage methods, this method provides a supply of environmentally friendly and technologically suitable raw materials for the stable operation of sugar production during the off-season.

References

- Odhaib, I. H. (2025). The Producer’s Responsibility for Genetically Modified Foods: a Comparative Study. Journal of Lifestyle and SDGs Review, 5 (1), e04572. https://doi.org/10.47172/2965-730x.sdgsreview.v5.n01.pe04572

- McGrath, J. M., Fugate, K. K.; Preedy, V. R. (2012). Analysis of Sucrose from Sugar Beet. Dietary Sugars: Chemistry, Analysis, Function and Effects. RSC Publishing, 526–545. https://doi.org/10.1039/9781849734929-00526

- Bohigas, L. (2025). Sugar and slavery. Revista Econòmica de Catalunya, 91. Available at: https://www.researchgate.net/publication/393007066_Sugar_and_Slavery

- Kandel, S. L., Eide, J. D., Firrincieli, A., Finger, F. L., Lafta, A. M., Fugate, K. K. (2024). Sugar beet root susceptibility to storage rots and downregulation of plant defense genes increases with time in storage. Scientific Reports, 14 (1). https://doi.org/10.1038/s41598-024-78323-4

- Hlevaskiy, V., Sydorova, I., Kuyanov, V. (2023). Accounting of physical qualities of root crops during sugar beet reception and storage. Agrobìologìâ, 2 (183), 137–145. https://doi.org/10.33245/2310-9270-2023-183-2-137-145

- Błaszczyk, I., Molska, M., Bąk, P., Wojtczak, M. (2017). Microbiological stability of sugar beets during their storage. International Sugar Journal, 119. Available at: https://www.researchgate.net/publication/328393746_Microbiological_stability_of_sugar_beets_during_their_storage

- Kazimova, I., Mikayilov, V., Omarova, E., Gasimova, A., Nabiyev, A. (2025). Establishment of regularities of biochemical transformations in grape berries during refrigerated storage with preliminary thermal treatment. Technology Audit and Production Reserves, 1 (3 (81)), 31–38. https://doi.org/10.15587/2706-5448.2025.323631

- Kulanbay, K., Akmullayeva, А., Rinar, А., Abilmazhin, М., Sarsembaev, K. (2021). Development of proposals for creating a biological product to increase the shelf life of sugar beet seed material. Izdenister Natigeler, 2 (90), 161–169. https://doi.org/10.37884/2-2021/16

- Fataliyev, H., Aghazade, Y., Mikayilov, V., Heydarov, E., Gadimova, N., Imanova, K. et al. (2025). Identifying the influence of various factors on the composition of juices and wines obtained from the autonomous Bayan Shirey grape variety. Eastern-European Journal of Enterprise Technologies, 3 (11 (135)), 89–102. https://doi.org/10.15587/1729-4061.2025.332592

- Moslemzadeh, E. Ə., Qasımova, A. A., Nəbiyev, Ə. Ə., Tağıyev, M. M. (2007). Şəkər çuğundurunun emala qədər saxlanmasında invertaza və pektinesteraza fermenlərinin tədqiqi. AMEA Xəbərləri, Biologiya Elmləri, 5–6, 170–180.

- Trnka, J., Kumbár, V., Nedomová, Š., Pytel, R., Buchar, J. (2018). Influence of sugar beet storage duration on root responseto non-destructive impacts. International Agrophysics, 32 (3), 421–428. https://doi.org/10.1515/intag-2017-0032

- English, W. (2023). Long-term post-harvest field storage of sugar beet (Beta vulgaris subsp. vulgaris). [Doctoral Thesis; Swedish University of agricultural sciences]. https://doi.org/10.54612/a.66e26trq96

- Klotz, K. L., Finger, F. L. (2001). Activity and Stability of a Soluble Acid Invertase from Sugarbeet Roots. Journal of Sugarbeet Research, 38 (2), 121–138. https://doi.org/10.5274/jsbr.38.2.121

- Voragen, A. G. J., Oosterveld, A., Schols, H. A., Beldman, G. (1997). Pectic substances from sugar beet pulp: Extraction and fractionation, structural features, functional properties and enzymic modification. IVth Workshop on Carbohydrates as Raw Material. Vienne, 29.

- Bian, C., Ji, L., Xu, W., Dong, S., Pan, N. (2024). Research Progress on Bioactive Substances of Beets and Their Functions. Molecules, 29 (19), 4756. https://doi.org/10.3390/molecules29194756

- Hutnan, M., Drtil, M., Mrafkova, L. (2000). Anaerobic biodegradation of sugar beet pulp. Biodegradation, 11 (4), 203–211. https://doi.org/10.1023/a:1011139621329

- Orazizadeh, M. R., Hosseinpour, M., Fasahat, P. (2020). The effect of crop rotation on performance and qualitative characteristics of sugar beet. Notulae Scientia Biologicae, 12 (3), 711–718. https://doi.org/10.15835/nsb12310755

- Lysakov, A. A., Lubentsova, E. V., Apodgorny, S., Ozhogova, E. V. (2021). Magnetic Treatment of Sugar Beet to Reduce Weight Loss during Storage. IOP Conference Series: Earth and Environmental Science, 852 (1), 012064. https://doi.org/10.1088/1755-1315/852/1/012064

- Vosper, F. C., Backer, L. F., Schuler, R. T. (1983). Ventilation and freezing of stored sugar beets. Transactions of the ASAE, 26 (1), 0301–0304. https://doi.org/10.13031/2013.33925

- Hamze, H., Mohammadian, R., Mansuri, H. (2025). Evaluation of yield potential and phenotypic and genetic relationships of traits affecting white sugar yield in new foreign genotypes of sugar beet. Iranian Journal of Field Crop Science, 56 (2), 105–120. https://doi.org/10.22059/ijfcs.2024.383180.655104

- Myers, P.; Flamini, R., Traldi, P. (Eds.) (2011). Mass Spectrometry in Grape and Wine Chemistry. Chromatographia, 73 (11–12), 1241–1241. https://doi.org/10.1007/s10337-011-1987-5

- ISO 5350-2:2006 – Pulps: Estimation of dirt and shives – Part 2: Inspection of mill sheeted pulp by transmitted light (2006). International Organization for Standardization. Available at: https://www.iso.org/obp/ui/ru/#iso:std:iso:5350:-2:ed-3:v1:en

- ISO 22000:2005 – Food safety management systems: Requirements for any organization in the food chain (2005). International Organization for Standardization. Available at: https://www.iso.org/obp/ui/#iso:std:iso:22000:ed-1:v1:en

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Ahad Nabiyev, Afet Gasimova, Ilhama Kazimova, Sevinj Maharramova, Gunash Nasrullayeva, Mehriban Yusifova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.