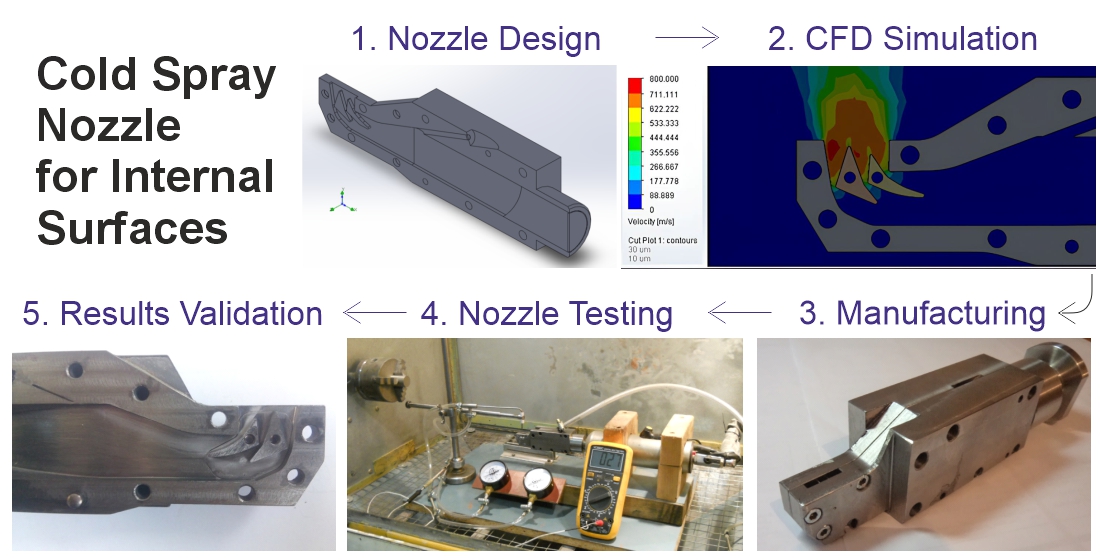

Development of special cold spray nozzle for internal surface coating deposition

DOI:

https://doi.org/10.15587/2706-5448.2025.345022Keywords:

coating, nozzle geometry, powder, optimization, CFD modeling, part recoveryAbstract

Increasing the service life of parts by forming protective and restorative coatings through cold spraying (CS) is a tough scientific and technical challenge. The object of the study is the process of accelerating powder particles in a supersonic rotating nozzle for CS. For CS, it is difficult, and sometimes even impossible, to form coatings on internal and hard-to-reach surfaces. In the practice of using the technology, this is considered one of the most problematic places, which limits the capabilities of the technology.

This paper focused on improving the CS process by developing a new supersonic rotating nozzle for coating deposition on internal and hard-to-reach surfaces of parts, establishing the regularities of the trajectory of motion and acceleration of powder particles in it. During the study, classical methods of computational gas dynamics were used, including methods for investigating two-phase flows. Experimental verification of the modeling results was performed by the pneumatic method of determining the Mach number using a Pitot-Prandtl tube. Numerical modeling of CS processes was performed for two designed rotating nozzles – two-channel and three-channel. The values of the maximum velocity of aluminum powder particles with a diameter of 10 μm at an air stagnation pressure of 4.0 MPa and stagnation temperature of 550°C were obtained: 558 m/s for the two-channel nozzle, and 585 m/s for the three-channel one, which is sufficient for adhesion of particles to the substrate. A three-channel nozzle was chosen for manufacturing and experimental testing. The difference between the experimental and calculated values of the Mach number at the nozzle outlet did not exceed 10%. The presence of two additional nozzles, located in the main channel and directed at an angle to the main flow direction, ensures the rotation of the flow with particles from the initial direction at an angle of approximately 75 degrees, which satisfies the requirements for forming CS coatings.

References

- Meng, F., Zhou, Y., Zhang, H., Wang, Z., Liu, D., Cao, S. et al. (2025). Development and Research Status of Wear-Resistant Coatings on Copper and Its Alloys: Review. Crystals, 15 (3), 204. https://doi.org/10.3390/cryst15030204

- Zhang, Z., Tarelnyk, V., Konoplianchenko, I., Guanjun, L., Xin, D., Yao, J. (2023). Characterization of Tin Bronze Substrates Coated by Ag + B83 through Electro-Spark Deposition Method. Surface Engineering and Applied Electrochemistry, 59 (2), 220–230. https://doi.org/10.3103/s1068375523020187

- Dolmatov, A. I., Dan’ko, K. A., Neveshkin, Yu. A. (2016). Modelling of Distribution of Particles in a Two-Phase Flow of Detonation – Plasma Device. Metallofizika i Noveishie Tekhnologii, 36 (11), 1533–1546. https://doi.org/10.15407/mfint.36.11.1533

- Breus, A., Abashin, S., Serdiuk, O., Sysoiev, Iu. (2023). Synthesis of metallic alloy particles on flat graphitic interfaces in arc discharge. Archives of Materials Science and Engineering, 121 (2), 49–59. https://doi.org/10.5604/01.3001.0053.8486

- Guo, D., Kazasidis, M., Hawkins, A., Fan, N., Leclerc, Z., MacDonald, D. et al. (2022). Cold Spray: Over 30 Years of Development Toward a Hot Future. Journal of Thermal Spray Technology, 31 (4), 866–907. https://doi.org/10.1007/s11666-022-01366-4

- Singh, H., Kumar, M., Singh, R. (2022). An overview of various applications of cold spray coating process. Materials Today: Proceedings, 56, 2826–2830. https://doi.org/10.1016/j.matpr.2021.10.160

- Ashokkumar, M., Thirumalaikumarasamy, D., Sonar, T., Deepak, S., Vignesh, P., Anbarasu, M. (2022). An overview of cold spray coating in additive manufacturing, component repairing and other engineering applications. Journal of the Mechanical Behavior of Materials, 31 (1), 514–534. https://doi.org/10.1515/jmbm-2022-0056

- Forero-Sossa, P. A., Giraldo-Betancur, A. L., Poblano-Salas, C. A., Gutierrez-Pérez, A. I., Rodríguez-Vigueras, E. M., Corona-Castuera, J., Henao, J. (2022). Nozzle Geometry and Particle Size Influence on the Behavior of Low Pressure Cold Sprayed Hydroxyapatite Particles. Coatings, 12 (12), 1845. https://doi.org/10.3390/coatings12121845

- Kun, T., Wenjie, H., Yurong, W. (2024). Optimization of Cold Spray Nozzles Based on the Response Surface Methodology. Journal of Engineering Sciences, 11 (1), F1–F11. https://doi.org/10.21272/jes.2024.11(1).f1

- Zahiri, S. H., Gulizia, S., Prentice, L. (2020). An Overview of Cold Spray Additive Technology in Australia for Melt-less Manufacture of Titanium. MATEC Web of Conferences, 321, 03011. https://doi.org/10.1051/matecconf/202032103011

- Faizan-Ur-Rab, M., Zahiri, S. H., Masood, S. H., Jahedi, M., Nagarajah, R.; Nastac, L., Zhang, L., Thomas, B. G., Zhu, M., Ludwig, A., Sabau, A. S. (Eds.) (2016). 3D CFD Multicomponent Model for Cold Spray Additive Manufacturing of Titanium Particles. CFD Modeling and Simulation in Materials Processing 2016. The Minerals, Metals & Materials Series. Cham: Springer, 213–220. https://doi.org/10.1007/978-3-319-65133-0_26

- Hu, W., Shorinov, O. (2024). Optimization of Technological Parameters for Cold Spraying Using the Response Surface Method. Journal of Engineering Sciences, 11 (2), F1–F8. https://doi.org/10.21272/jes.2024.11(2).f1

- Dolmatov, A. I., Polyviany, S. A. (2021). Interaction of Solid Particles from a Gas Stream with the Surface of a Flat Nozzle. Metallofizika i noveishie tekhnologii, 43 (3), 319–328. https://doi.org/10.15407/mfint.43.03.0319

- Shorinov, O., Volkov, A., Neveshkin, Y., Danko, K., Kalinichenko, N.; Ivanov, V., Pavlenko, I., Liaposhchenko, O., Machado, J., Edl, M. (Eds.) (2023). Theoretical Study of Powder Particle Parameters in a Modified Cold Spray Nozzle. Advances in Design, Simulation and Manufacturing VI. DSMIE 2023. Lecture Notes in Mechanical Engineering. Cham: Springer, 168–176. https://doi.org/10.1007/978-3-031-32774-2_17

- Cao, C., Li, W., Zhang, Z., Yang, X., Xu, Y. (2022). Cold Spray Additive Manufacturing of Ti6Al4V: Special Nozzle Design Using Numerical Simulation and Experimental Validation. Coatings, 12 (2), 210. https://doi.org/10.3390/coatings12020210

- Garmeh, S., Jadidi, M. (2022). Numerical Study on Particle Behavior and Deposition Accuracy in Cold Spray Additive Manufacturing. Coatings, 12 (10), 1546. https://doi.org/10.3390/coatings12101546

- Shorinov, O., Volkov, A., Dolmatov, A., Balushok, K.; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Pavlenko, I. (Eds.) (2023). Numerical Simulation of a Modified Nozzle for Cold Spraying. Advanced Manufacturing Processes V. Cham: Springer, 571–579. https://doi.org/10.1007/978-3-031-42778-7_53

- Tryfonov, O., Teodorczyk, A., Shypul, O., Rudy, W., Garin, V., Myntiuk, V., Tkachenko, D. (2025). Numerical Study and Model Validation of Low-Pressure Hydrogen-Air Combustion in a Closed Vessel. Computation, 13 (2), 54. https://doi.org/10.3390/computation13020054

- SOLIDWORKS Flow Simulation. Available at: https://www.solidworks.com/product/solidworks-flow-simulation Last accessed: 03.06.2025

- Schmidt, T., Gärtner, F., Assadi, H., Kreye, H. (2006). Development of a generalized parameter window for cold spray deposition. Acta Materialia, 54 (3), 729–742. https://doi.org/10.1016/j.actamat.2005.10.005

- Nastic, A., Jodoin, B., Legoux, J.-G., Poirier, D. (2021). Particle Impact Characteristics Influence on Cold Spray Bonding: Investigation of Interfacial Phenomena for Soft Particles on Hard Substrates. Journal of Thermal Spray Technology, 30 (8), 2013–2033. https://doi.org/10.1007/s11666-021-01272-1

- Canales, H., Lytvynov, A., Markovich, S., Dolmatov, A. (2014). Computational fluid dynamics modeling of a low pressure cold spraying nozzle. Mechanics and Mechanical Engineering, 1, 157–163. Available at: https://repository.kpi.kharkov.ua/handle/KhPI-Press/16980

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleksandr Shorinov, Andrii Volkov, Nina Savchenko, Serhii Markovych, Kostiantyn Danko, Roman Ipatov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.