Design optimization of a mold for producing a complex-geometry blade

DOI:

https://doi.org/10.15587/2706-5448.2025.348178Keywords:

stress-strain state, prototype, polymer molds, bolt pre-tightening simulation, additive manufacturing of toolingAbstract

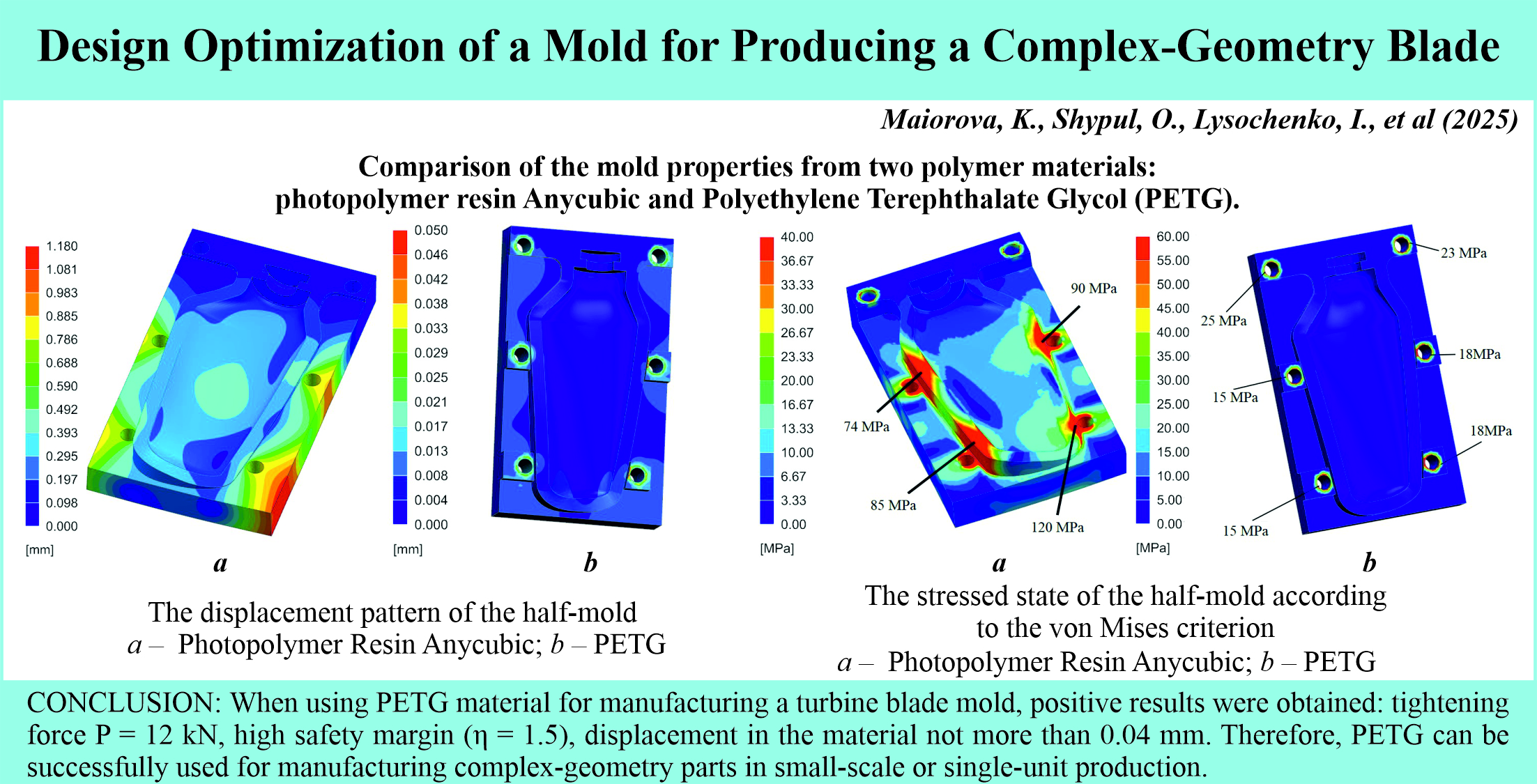

The object of research is a mold with complex geometry for casting a turbine blade prototype, made by 3D printing from Anycubic photopolymer resin and PETG (Polyethylene Terephthalate Glycol) polymer.

Problem to be solved: ensuring the necessary strength and rigidity of the mold during the assembly of half-molds by bolted connection with preliminary axial tension.

Using Siemens NX Advanced Simulation, finite element models of the mold were created and calculated. It was found that with significant preliminary axial tension, the limit stresses in the bolt hole area are exceeded, which limits the use of photopolymer resin. Reducing the tightening force improves the performance, but leaves a minimum margin of safety. The rigidity of the mold can be increased by using support pads, but such a design causes stress concentration in the bolted connections. The optimal calculation result was achieved when using PETG material: the safety margin increased to η = 1.5, and the displacements did not exceed 0.04 mm. The PETG polymer, unlike photopolymer resin, is more elastic and plastic in the hardened state with higher strength. This allows to distribute the load over the material. The results obtained can be used for the manufacture of molds for casting and tooling in general, especially for a small batch of parts. The practical application of the technology under consideration is possible provided that the input parameters are correctly combined: material, bolt pre-tightening force and the use of support pads. PETG is recommended for molds operating under increased loads.

References

- Zmarzły, P., Gogolewski, D., Kozior, T. (2020). Design guidelines for plastic casting using 3D printing. Journal of Engineered Fibers and Fabrics, 15. https://doi.org/10.1177/1558925020916037

- Parthiban, P., Vijayan, S., Doyle, P. S., Hashimoto, M. (2021). Evaluation of 3D-printed molds for fabrication of non-planar microchannels. Biomicrofluidics, 15 (2). https://doi.org/10.1063/5.0047497

- Gao, W., Zhang, Y., Ramanujan, D., Ramani, K., Chen, Y., Williams, C. B. et al. (2015). The status, challenges, and future of additive manufacturing in engineering. Computer-Aided Design, 69, 65–89. https://doi.org/10.1016/j.cad.2015.04.001

- Vigogne, M., Zschech, C., Stommel, M., Thiele, J., Kühnert, I. (2024). Combining Injection Molding and 3D Printing for Tailoring Polymer Material Properties. Macromolecular Materials and Engineering, 309 (11). https://doi.org/10.1002/mame.202400210

- Grzejda, R., Warzecha, M., Urbanowicz, K. (2022). Determination of the Preload of Bolts for Structural Health Monitoring of a Multi-Bolted Joint: FEM Approach. Lubricants, 10 (5), 75. https://doi.org/10.3390/lubricants10050075

- Chai, R., Yu, Z., Xu, H., Huang, X., Mao, K., Zhou, W. (2025). Pre-tightening Force Analysis of Different Bolt Models Based on Finite Element Simulation. Advances in Engineering Technology Research, 14 (1), 496. https://doi.org/10.56028/aetr.14.1.496.2025

- Belardi, V. G., Fanelli, P., Vivio, F.; Chen, S. M. (Ed.) (2022). Comparative Analysis of FE Modeling Techniques for Single-Lap Multi-column Composite Bolted Joints. Proceedings of 10th International Conference on Chemical Science and Engineering. Singapore: Springer, 121–128. https://doi.org/10.1007/978-981-19-4290-7_14

- Lupkin, B., Maiorova, K., Vorobiov, I., Nikichanov, V., Sikulskyi, V.; Nechyporuk, M., Pavlikov, V., Kritskiy, D. (Eds.) (2023). Study of Drilling Cutting Modes Impact on Shrinkage and Surface Roughness of Holes in Composite Materials. Integrated Computer Technologies in Mechanical Engineering – 2022. Cham: Springer, 88–98. https://doi.org/10.1007/978-3-031-36201-9_8

- Myntiuk, V., Shypul, O., Tryfonov, O., Tsegelnyk, Y. (2025). Axisymmetric problem of smoothing the surface of a viscous liquid by surface tension forces. Radioelectronic and Computer Systems, 2025 (1), 113–125. https://doi.org/10.32620/reks.2025.1.08

- Maiorova, K., Lysochenko, I., Skyba, O., Suslov, A., Antonyuk, V.; Pavlenko, D., Tryshyn, P., Honchar, N., Kozlova, O. (Eds.) (2025). Analysis of Modern Approaches to Approbation of Aircraft Parts Geometric Data Digitization by Reverse Engineering. Smart Innovations in Energy and Mechanical Systems. Cham: Springer, 264–273. https://doi.org/10.1007/978-3-031-95191-6_25

- Onopchenko, A., Horbachov, O., Sorokin, V., Dudukalov, Y., Kurin, M.; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Pavlenko, I. (Eds.) (2022). Optimal Conditions for Deformation of Stamping-Drawing Process from Aviation Materials. Advanced Manufacturing Processes IV. Cham: Springer, 109–118. https://doi.org/10.1007/978-3-031-16651-8_11

- Shevel, V., Kritskiy, D., Popov, O. (2022). Toward Building a Functional Image of the Design Object in CAD. Computation, 10 (8), 134. https://doi.org/10.3390/computation10080134

- Onopchenko, A. V., Kurin, M. O., Shyrokyi, Y. V. (2024). Ensuring quality of stamping sheet aviation parts. Progress in Physics of Metals, 25 (2), 320–363. https://doi.org/10.15407/ufm.25.02.320

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Kateryna Maiorova, Olga Shypul, Ihor Lysochenko, Taras Hoptar, Liudmyla Kapitanova, Iryna Voronko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.