Evaluation of pH-modified chickpea protein isolate as a functional fat replacer in German-style cooked sausages

DOI:

https://doi.org/10.15587/2706-5448.2025.348365Keywords:

chickpea protein isolate, pH adjustment, fat substitute, meat products, traditional sausages, vegetable proteinAbstract

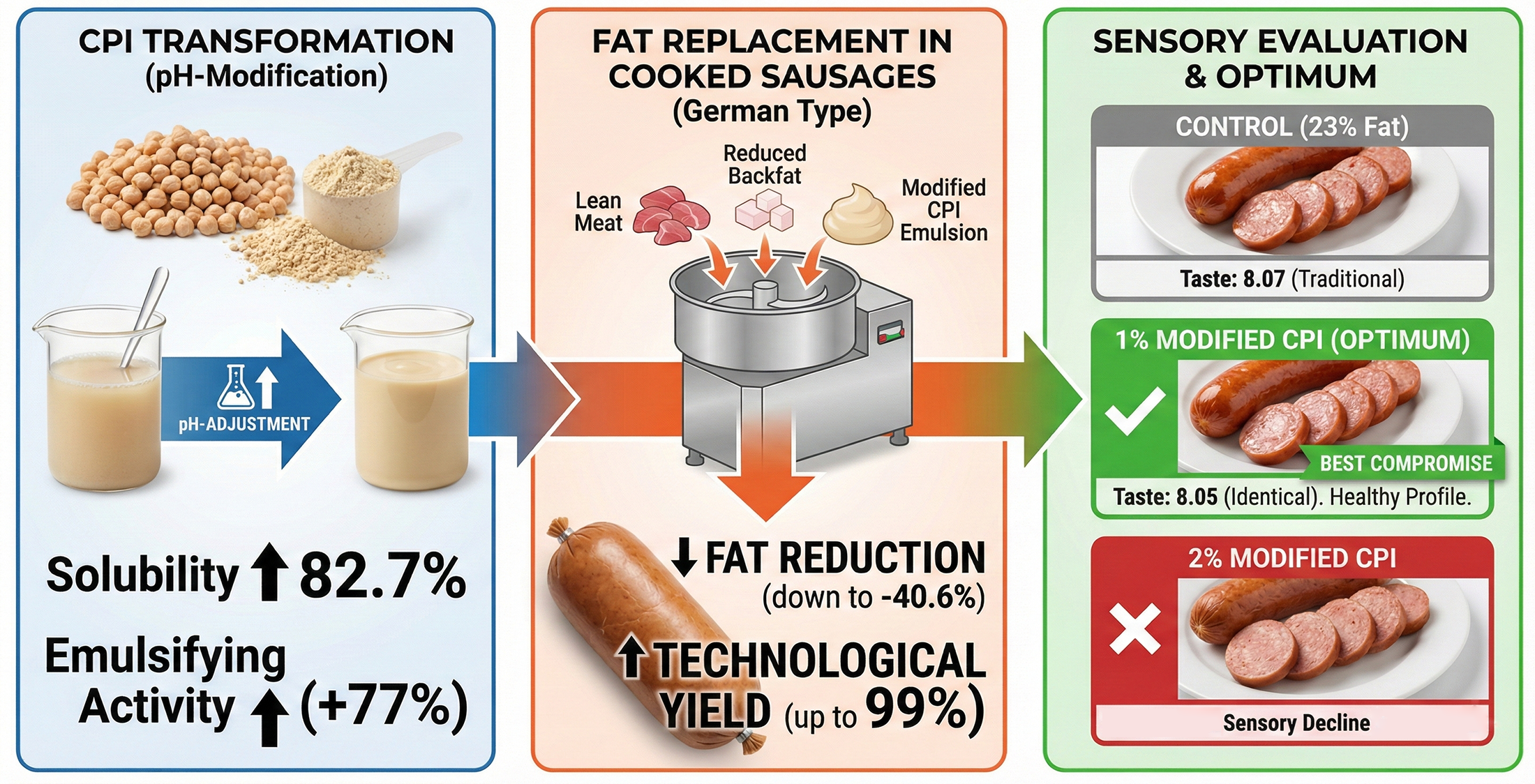

The object of research is boiled German-type sausages with reduced fat content. The technological complexity of fat reduction in traditional meat emulsions is a major problem, which inevitably leads to a deterioration in both physicochemical parameters (emulsion stability) and sensory characteristics, such as texture and juiciness. This study was aimed at assessing the ability of chickpea protein isolate (CPI), modified using the pH-adjustment method, to act as a functional fat substitute. At the first stage, a comparison of the techno-functional properties of the modified isolate (solubility, WHC, OHC, EAI and ESI) with those of the native protein was carried out. All functional parameters of CPI were significantly improved by pH-treatment (p < 0.05). The solubility increased from 24.33% to 82.67%, and the emulsifying activity index (EAI) from 27.33 to 48.33 m²/g, which are significant changes for meat systems. For the experiment, modified CPI was introduced at concentrations of 1% (sample CPI1) and 2% (sample CPI2) for partial fat replacement. This was compared with the results of the high-fat control (23%). This combination allowed to significantly (p < 0.05) reduce the mass fraction of fat in the finished products. Sample CPI1 showed a decrease of 26.1%, and sample CPI2 showed a decrease of 40.6%. At the same time, the technological yield showed a clear trend towards growth (from 90.67% to 99.00%). Sensory analysis (on a 9-point scale) showed that sample CPI1 (1% CPI) had a sensory profile that was statistically indistinguishable (p > 0.05) from the control in all parameters, including taste (8.05 vs. 8.07) and aroma (7.63 vs. 7.78). However, sample CPI2 showed a significant deterioration in organoleptic properties (p < 0.05). Thus, pH-modified CPI proved its effectiveness as a fat substitute, and the 1% dosage was identified as the best method for preparing healthy cooked sausages without compromising on taste.

References

- Onyeaka, H., Nwaiwu, O., Obileke, K., Miri, T., Al‐Sharify, Z. T. (2023). Global nutritional challenges of reformulated food: A review. Food Science & Nutrition, 11 (6), 2483–2499. https://doi.org/10.1002/fsn3.3286

- Bronzato, S., Durante, A. (2017). A Contemporary Review of the Relationship between Red Meat Consumption and Cardiovascular Risk. International Journal of Preventive Medicine, 8 (1). https://doi.org/10.4103/ijpvm.ijpvm_206_16

- Helikh, A., Filon, A. (2025). Biochemical variability of vegetable juice powders: a key factor in modulating the physicochemical properties and safety profile of vegan fermented sausages. Technology Audit and Production Reserves, 4 (3 (84)), 52–59. https://doi.org/10.15587/2706-5448.2025.334830

- Helikh, A., Filon, A. (2025). Study of the amino acid profile of alternative proteins (Helix pomatia, Lissachatina fulica, Helix aspersa) and their potential application in a healthy diet: optimization of a modern brandade recipe. Technology Audit and Production Reserves, 2 (3 (82)), 71–79. https://doi.org/10.15587/2706-5448.2025.326896

- Peerzade, I. J., Kudre, T., Halami, P. M.; Yaradoddi, J. S., Meti, B. S., Mudgulkar, S. B., Agsar, D. (Eds.) (2024). Poultry and Meat Processing. Frontiers in Food Biotechnology. Singapore: Springer, 427–444. https://doi.org/10.1007/978-981-97-3261-6_23

- Egea, M., Álvarez, D., Peñaranda, I., Panella-Riera, N., Linares, M. B., Garrido, M. D. (2020). Fat Replacement by Vegetal Fibres to Improve the Quality of Sausages Elaborated with Non-Castrated Male Pork. Animals, 10 (10), 1872. https://doi.org/10.3390/ani10101872

- Morales-Olán, G., Antonieta Ríos-Corripio, M., Rojas-López, M., Velasco-Velasco, J., Selene Hernández-Cázares, A. (2025). Effects of flour, starch and pea (Pisum sativum L.) protein as fat substitutes during storage of pork sausages. Czech Journal of Food Sciences, 43 (3), 194–204. https://doi.org/10.17221/211/2024-cjfs

- Navarré, A., Musto, L., Nazareth, T. (2025). Beyond Meat Substitution: A Multifaceted Review of Plant-Based and Alternative Proteins, from Environmental Impact to Analytical Technologies. Foods, 14 (13), 2312. https://doi.org/10.3390/foods14132312

- Partanen, M., Liikonen, V., Väkeväinen, K., Gómez Gallego, C., Kolehmainen, M. (2025). Digestion, Metabolism, and Health Effects of Plant Proteins and Their Food Formulations: A Systematic Scoping Review of Clinical Postprandial Studies and in vitro Methods. Food Reviews International, 1–30. https://doi.org/10.1080/87559129.2025.2525430

- van den Berg, L. A., Mes, J. J., Mensink, M., Wanders, A. J. (2022). Protein quality of soy and the effect of processing: A quantitative review. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.1004754

- Patil, N. D., Bains, A., Sridhar, K., Bhaswant, M., Kaur, S., Tripathi, M. et al. (2024). Extraction, Modification, Biofunctionality, and Food Applications of Chickpea (Cicer arietinum) Protein: An Up-to-Date Review. Foods, 13 (9), 1398. https://doi.org/10.3390/foods13091398

- Zhang, Y., Huang, X., Zeng, X., Li, L., Jiang, Y. (2023). Preparation, functional properties, and nutritional evaluation of chickpea protein concentrate. Cereal Chemistry, 100 (2), 310–320. https://doi.org/10.1002/cche.10608

- Zhang, J., Liu, Q., Chen, Q., Sun, F., Liu, H., Kong, B. (2022). Synergistic modification of pea protein structure using high-intensity ultrasound and pH-shifting technology to improve solubility and emulsification. Ultrasonics Sonochemistry, 88, 106099. https://doi.org/10.1016/j.ultsonch.2022.106099

- Chen, Q., Guan, J., Wang, Z., Wang, Y., Wang, X., Chen, Z. (2024). Improving the Gelation Properties of Pea Protein Isolates Using Psyllium Husk Powder: Insight into the Underlying Mechanism. Foods, 13 (21), 3413. https://doi.org/10.3390/foods13213413

- Gao, D., Helikh, A., Filon, A., Duan, Z., Vasylenko, O. (2022). Effect of pH-shifting treatment on the gel properties of pumpkin seed protein isolate. Journal of Chemistry and Technologies, 30 (2), 198–204. https://doi.org/10.15421/jchemtech.v30i2.241145

- Morr, C. V., German, B., Kinsella, J. E., Regenstein, J. M., Buren, J. P. V., Kilara, A. et al. (1985). A Collaborative Study to Develop a Standardized Food Protein Solubility Procedure. Journal of Food Science, 50 (6), 1715–1718 https://doi.org/10.1111/j.1365-2621.1985.tb10572.x

- Bradford, M. M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72 (1–2), 248–254. https://doi.org/10.1016/0003-2697(76)90527-3

- Quinn, J. R., Paton, D. (1979). A practical measurement of water hydration capacity of protein materials. Cereal Chemistry, 56 (1), 38–40. Available at: https://www.cerealsgrains.org/publications/cc/backissues/1979/Documents/chem56_38.pdf

- Lin, M. J., Humbert, E. S., Sosulski, F. W. (1974). Certain functional properties of sunflower meal products. Journal of Food Science, 39 (2), 368–370. https://doi.org/10.1111/j.1365-2621.1974.tb02896.x

- Pearce, K. N., Kinsella, J. E. (1978). Emulsifying properties of proteins: evaluation of a turbidimetric technique. Journal of Agricultural and Food Chemistry, 26 (3), 716–723. https://doi.org/10.1021/jf60217a041

- Kjeldahl, J. (1883). Neue Methode zur Bestimmung des Stickstoffs in organischen Körpern. Zeitschrift Für Analytische Chemie, 22 (1), 366–382. https://doi.org/10.1007/bf01338151

- Soxhlet, F. (1879). Die gewichtsanalytische Bestimmung des Milchfettes. Dinglers Polytechnisches Journal, 232, 461–465. Available at: https://cyberlipid.gerli.com/wp-content/uploads/sites/3/2018/09/soxhlet.pdf

- Official methods of analysis of AOAC International (2022). AOAC International.

- Lawless, H. T., Heymann, H. (2010). Sensory Evaluation of Food. New York: Springer. https://doi.org/10.1007/978-1-4419-6488-5

- How to feed the world in 2050 (2009). Food and Agriculture Organization of the United Nations. Available at: https://www.fao.org/4/ak542e/ak542e00.pdf

- Leip, A., Billen, G., Garnier, J., Grizzetti, B., Lassaletta, L., Reis, S. et al. (2015). Impacts of European livestock production: nitrogen, sulphur, phosphorus and greenhouse gas emissions, land-use, water eutrophication and biodiversity. Environmental Research Letters, 10 (11), 115004. https://doi.org/10.1088/1748-9326/10/11/115004

- Prymenko, V., Sefikhanova, K., Helikh, A., Golovko, M., Vasylenko, O. (2022). Choice justification of dairy raw materials according to indicators of their structure for obtaining selenium-protein dietary supplements. Journal of Chemistry and Technologies, 30 (1), 79–87. https://doi.org/10.15421/jchemtech.v30i1.241139

- Yang, F., Ren, L., Sun, J., Gu, C. (2025). A study of the purchase intention of alternative foods. Scientific Reports, 15 (1). https://doi.org/10.1038/s41598-025-90014-2

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Iryna Kurmakova, Nadiia Lapytska, Hanna Novik , Olena Bondar, Olha Vasylenko, Tetiana Holovko , Maksym Zherebkin, Iryna Levchenko, Oleh Starynskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.