Development of gluten-free products technology using flax flour

DOI:

https://doi.org/10.15587/2706-5448.2025.326217Keywords:

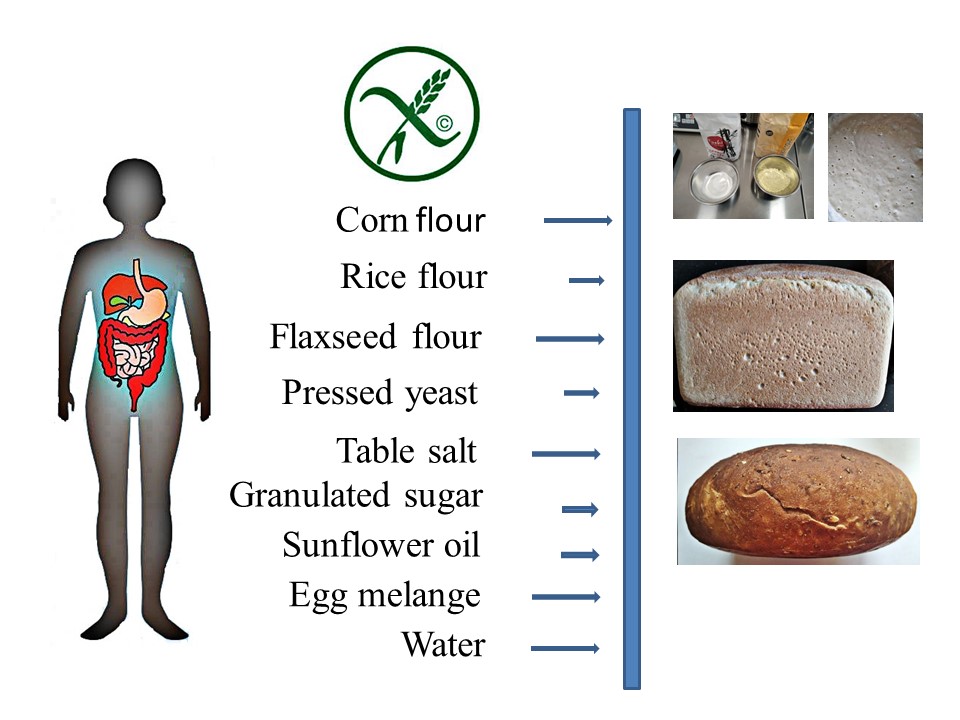

corn flour, rice flour, flax flour, modeling compositions, gluten-free bakery productsAbstract

The object of research is the production of gluten-free products. 4 samples of dough and finished products with different ratios of corn, rice and flax flour were studied. Organoleptic analysis showed that compared to the assessment of the control sample (4.7 points), sample No. 3 (4.9 points) with a ratio of corn, rice and flax flour 60:20:20 (experiment 3) is rational.

Europe and other countries of the world are showing increased interest in the implementation of innovative technologies for the production of special and functional food products. Therefore, the current task is to introduce new technologies and functional formulations into production, taking into account the needs of today, aimed at preserving and increasing the biological value of food products.

It was found that the physical and chemical indicators of the finished gluten-free bakery product in terms of porosity, acidity, and crumb moisture exceed the control sample. The results of the studies show that an increase in the amount of rice and flax flour leads to an increase in dough porosity by 2 % compared to the control sample. The acidity of the dough increased from 2.70 degrees to 3.1 degrees and exceeded the control sample by 0.3 degrees. The dimensional stability is almost the same as that of the control sample. The specific volume compared to the control increased by 20 cm3/100 g and amounted to 268 cm3/100 g.

Based on the research results, a basic technological scheme of production has been developed and substantiated, parameters and modes of the technological process have been given. The possibility of creating functional technologies and recipes not only with high sensory, physicochemical quality indicators, but also with high nutritional value has been confirmed. This is achieved due to the content of vegetable proteins, unsaturated fatty acids and dietary fiber, minerals and vitamins in flax flour, which have a positive effect on lipid metabolism.

References

- Marciniak-Łukasiak, K., Dłużewska, E. (2018). Pseudozboża w żywności bezglutenowej. Przemysł Spożywczy, 72 (9), 46–50.

- Cappelli, A., Oliva, N., Cini, E. (2020). A systematic review of gluten-free dough and bread: Dough rheology, bread characteristics, and improvement strategies. Applied Sciences, 10 (18), 6559. https://doi.org/10.3390/app10186559

- Skendi, A., Papageorgiou, M., Varzakas, T. (2021). High protein substitutes for gluten in gluten-free bread. Foods, 10 (9), 1997. https://doi.org/10.3390/foods10091997

- Culetu, A., Duta, D. E., Papageorgiou, M., Varzakas, T. (2021). The role of hydrocolloids in gluten-free bread and pasta; rheology, characteristics, staling and glycemic index. Foods, 10 (12), 3121. https://doi.org/10.3390/foods10123121

- Guimaraes, R. M., Pimentel, T. C., De Rezende, T. A. M., Silva, J. S., Falcao, H. G., Ida, E. I. et al. (2019). Gluten-free bread: Effect of soy and corn co-products on the quality parameters. European Food Research and Technology, 245 (7), 1365–1376. https://doi.org/10.1007/s00217-019-03261-9

- Cederborg, A. C., Hultman, E., Magnusson, K. F. (2012). Living with children who have coeliac disease: a parental perspective. Child: Care, Health and Development, 38 (4), 484–489. https://doi.org/10.1111/j.1365-2214.2011.01273.x

- Makhynko, V. M. (2019). Scientific substantiation and development of the technology of high-protein bread products for consumers with an increased need for macronutrients. [Doctoral dissertation].

- Han, A., Romero, H. M., Nishijima, N., Ichimura, T., Handa, A., Xu, C. et al. (2019). Effect of egg white solids on the rheological properties and bread making performance of gluten-free batter. Food Hydrocolloids, 87, 287–296. https://doi.org/10.1016/j.foodhyd.2018.07.041

- Makhynko, V., Drobot, V., Zemlynska, М. (2018). Crumb briquettes for consumers with the increased protein needs. Scientific Works of National University of Food Technologies, 24 (3), 160–169. https://doi.org/10.24263/2225-2924-2018-24-3-19

- Mykhonik, L. A., Hetman, I. A., Bela, N. I., Bohdan, G. S. (2018). Quality indicators of spontaneous fermentation starters from cereal grain flour in the process of low-temperature canning. Food Resources, 11, 116–122. https://doi.org/10.31073/foodresources2018-11-13

- Păcularu-Burada, B., Turturică, M., Rocha, J. M., Bahrim, G.-E. (2021). Statistical approach to potentially enhance the postbiotication of gluten-free sourdough. Applied Sciences, 11 (11), 5306. https://doi.org/10.3390/app11115306

- Niland, B., Cash, B. D. (2018). Health benefits and adverse effects of a gluten-free diet in non-celiac disease patients. Gastroenterology & Hepatology, 14, 82–91.

- Păcularu-Burada, B., Georgescu, L. A., Vasile, M. A., Rocha, J. M., Bahrim, G.-E. (2020). Selection of wild lactic acid bacteria strains as promoters of postbiotics in gluten-free sourdoughs. Microorganisms, 8 (5), 643. https://doi.org/10.3390/microorganisms8050643

- Horach, O., Mukhalyk, K., Husar, A. (2021). Analiz vyrobnytstva funktsionalnykh bezhliutenovykh produktiv na osnovi vykorystannia vitchyznianoi syrovyny. Tavriiskyi naukovyi visnyk, 6, 94–100.

- DSTU 7517:2014. Khlib iz pshenychnoho boroshna. Zahalni tekhnichni umovy (2014). Kyiv.

- DSTU 7045:2008. Vyroby khlibobulochni. Metody vyznachennia fizyko-khimichnykh pokaznykiv (2010). Kyiv.

- Demirkesen Mert, I., Campanella, O. H., Sumnu, G., Sahin, S. (2016). Gluten-free sourdough bread prepared with chestnut and rice flour. Foodbalt, 26 (1), 239–242.

- Bernacchia, R., Preti, R., Vinci, G. (2014). Chemical composition and health benefits of flaxseed. Austin Journal of Nutrition and Food Sciences, 2 (8), 1045.

- Mercier, S., Villeneuve, S., Moresoli, C., Mondor, M., Marcos, B., Power, K. A. (2014). Flaxseed-enriched cereal-based products: a review of the impact of processing conditions. Comprehensive Reviews in Food Science and Food Safety, 13, 400–412. https://doi.org/10.1111/1541-4337.12075

- Lialyk, A., Bejko, L., Kuhtyn, M., Pokotylo, O. (2021). Use of flax oil in food production. Visnyk Agrarnoi Nauky, 99 (3), 78–83. https://doi.org/10.31073/agrovisnyk202103-10

- Bartkiene, E., Lele, V., Ruzauskas, M., Mayrhofer, S., Domig, K., Starkute, V. et al. (2020). Lactic acid bacteria isolation from spontaneous sourdough and their characterization including antimicrobial and antifungal properties evaluation. Microorganisms, 8 (1), 64. https://doi.org/10.3390/microorganisms8010064

- Singh, K. K., Mridula, D., Rehal, J., Barnwal, P. (2011). Flaxseed: a potential source of food, feed and fiber. Critical Reviews in Food Science and Nutrition, 51 (3), 210–222. https://doi.org/10.1080/10408390903537241

- Ahmed, I., Qazi, I. M., Li, Z., Ullah, J. (2016). Approved Methods of American Association of Cereal Chemists. American Association of Cereal Chemists. Arlington.

- Bouasla, A., Wójtowicz, A., Zidoune, M. N. (2017). Gluten-free precooked rice pasta enriched with legumes flours: physical properties, texture, sensory attributes and microstructure. LWT – Food Science and Technology, 75, 569–577. https://doi.org/10.1016/j.lwt.2016.10.005

- Dupasquier, C. M., Dibrov, E., Kneesh, A. L., Cheung, P. K., Lee, K. G., Alexander, H. K. (2007). Dietary flaxseed inhibits atherosclerosis in the LDL receptor-deficient mouse in part through antiproliferative and anti-inflammatory actions. American Journal of Physiology-Heart and Circulatory Physiology, 293 (5), H2394–H2402. https://doi.org/10.1152/ajpheart.00937.2006

- Harper, C. R., Edwards, M. J., DeFilippis, A. P., Jacobson, T. A. (2006). Flaxseed oil increases the plasma concentrations of cardioprotective (n-3) fatty acids in humans. The Journal of Nutrition, 136 (1), 83–87. https://doi.org/10.1093/jn/136.1.83

- Oomah, B. D., Berekoff, B., Li-Chan, C., Mazza, G., Kenaschuk, E., Duguid, S. (2007). Cadmium-binding protein components of flaxseed: influence of cultivar and location. Food Chemistry, 100 (1), 318–325. https://doi.org/10.1016/j.foodchem.2005.09.054

- Gorach, O. O. (2022). Conceptual basis of the formulation of gluten-free products based on the use of domestic plant raw materials. Moderní aspekty vědy: XXV. Mezinárodní Ekonomický Institut s.r.o. Česká republika, 373–388.

- Mykhalyk, K., Husar, A., Horach, O. (2021). Suchasnyi stan vyrobnytstva, yakosti ta bezpeky khlibobulochnykh vyrobiv. Suchasna nauka: stan ta perspektyvy rozvytku. Kherson, 315–319.

- Hryshchenko, A. M. (2011). Udoskonalennia tekhnolohii khliba z bezghliutenovoi syrovyny. [Extended abstract of PhD thesis; Nats. un-t kharch. tekhnol.].

- Dorokhovych, V. V. (2010). Naukove obgruntuvannia i rozroblennia tekhnolohii boroshnianykh kondyterskykh vyrobiv spetsialnoho diietychnoho spozhyvannia. [Doctoral dissertation; KNTEU].

- Lobachova, N. L. (2015). Tekhnolohiia bezghliutenovykh khlibobulochnykh vyrobiv z vykorystanniam kolahenvmisnykh bilkiv ta transhliutaminazy. [PhD dissertation; Kharkivskyi derzh. un-t kharch. ta torhivli].

- Hryshchenko, A. M., Drobot, V. I. (2014). Tekhnolohichni vlastyvosti bezghliutenovykh vydiv syrovyny. Naukovi pratsi, 46 (1), 162–166.

- Drobot, V. I., Sorochunska, U. S., Bondarenko, U. V., Renkas, O. I. (2019). Vykorystannia shrotu z nasinnia harbuza v tekhnolohii bezghliutenovoho khliba. Kharchova promyslovist, 26, 6–13.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Olga Gorach, Oksana Dzyundzya, Nataly Novikova, Nina Rezvykh

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.