Development of an information support methodology for quality assessment of the prepress process

DOI:

https://doi.org/10.15587/1729-4061.2022.266907Keywords:

information support of prepress quality assessment, prepress errors, color correction, “anticipatory” quality controlAbstract

A methodology for improving the information support of the prepress system by introducing new information blocks to prevent errors and predict the final result before the start of prepress operations is presented. Conceptual provisions for assessing the quality of the prepress process have been developed. These conceptual provisions have become the basis for solving the problem of systemic and random errors at the planning stage, created conditions for a significant reduction in prepress time. This parameterized form allows a formal description of operations, the determination of relevant quality indicators based on the formed parameters, and the development of databases and knowledge of the information support system for the anticipatory quality control of prepress.

Classification of factors that affect the quality of the prepress process was carried out. As a result, it is possible to exclude from further consideration the factors that are not important for assessing the prepress quality. The proposed factors form the basis of the knowledge base of the information system for assessing the quality of the prepress process.

The method of “anticipatory” quality control was developed. This method provides the detection of “bottlenecks” in each technological operation of the prepress process, as a result of which random and system errors can be avoided. The resulting indicators of the proposed method are the probability of an error, the probability of error-free execution of the technological operation, the cost of controlling the technological operation, and the cost of eliminating the error.

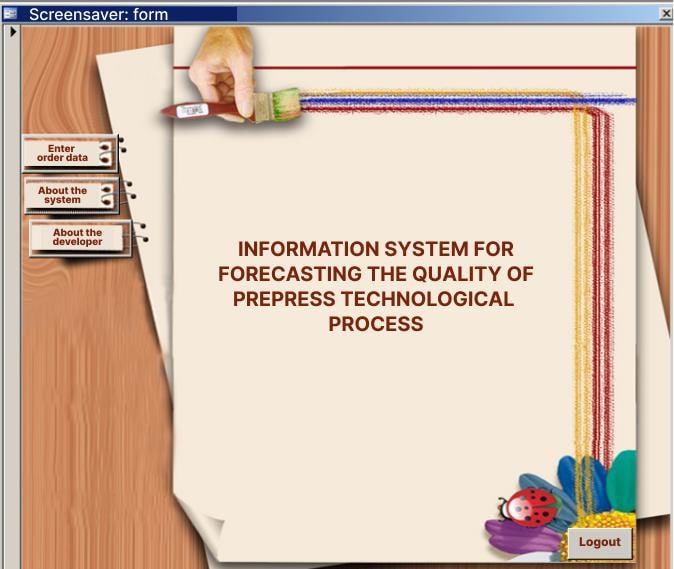

The information support method for the quality assessment of the prepress process is proposed. Implementation of the developed information support methodology for assessing the quality of the prepress process in the form of an information system for assessing the prepress quality was carried out. This information system allows automating the method of “anticipatory” quality control proposed in this study. Thus, on the example of the technological operation of color correction and color separation by the “CMYK color model” parameter based on the use of the expert knowledge base subsystem, the probability of an error is 1, and the cost of eliminating the error is $ 6.

References

- Khadzhynova, S., Jakucewicz, S. (2016). Sposoby drukowania cyfrowego. Łódź: Wydawnictwo Politechniki Łódzkiej, 242. Available at: https://docer.pl/doc/sn8nvs0

- Mulisch, M. (2014). Tissue-Printing. Springer, 40. doi: https://doi.org/10.1007/978-3-658-03867-0

- Babenko, V., Hrabovskyi, Y., Ivashura, A., Protasenko, O. (2020). Development of the Methodology for the Choice of Polygraphy Equipment for Printing on Cloth. Wseas Transactions on Environment and Development, 16, 305–315. doi: https://doi.org/10.37394/232015.2020.16.32

- Sun, W.-T., Lin, Y.-J. (2020). Systematic Review and Discussion on Final Artwork of Prepress Design. Education and Awareness of Sustainability. doi: https://doi.org/10.1142/9789811228001_0175

- Roudný, P., Držková, M. (2020). Use of prepress automation in the Czech Republic and examples of automated processing for selected prepress tasks. Proceedings - The Tenth International Symposium GRID 2020. doi: https://doi.org/10.24867/grid-2020-p72

- Cahyadi, T., Susanto, A., Riyono, D. (2021). Control of packaging print quality with an integrated production flow system in prepress. Kreator, 2 (1). doi: https://doi.org/10.46961/kreator.v2i1.283

- Rossitza, S. (2015). Offset Printing without Isopropyl Alcohol in Damping Solution. Energy Procedia, 74, 690–698. doi: https://doi.org/10.1016/j.egypro.2015.07.804

- Naumenko, M., Hrabovskyi, Y. (2018). Elaboration of methodology for designing a publishing and printing web portal. Eastern-European Journal of Enterprise Technologies, 2 (2 (92)), 14–22. doi: https://doi.org/10.15587/1729-4061.2018.126305

- Prinds, C., Hvidtjørn, D., Moestrup, L. (2018). Prepress Resonans mellem livets afslutning og livets begyndelse. Tidsskrift for Forskning i Sygdom Og Samfund, 15 (30). doi: https://doi.org/10.7146/tfss.v15i30.112705

- Safonov, I. V., Kurilin, I. V., Rychagov, M. N., Tolstaya, E. V. (2018). Adaptive Image Processing Algorithms for Printing. Springer, 304. doi: https://doi.org/10.1007/978-981-10-6931-4

- Al’boschiy, O., Dorokhov, O., Hrabovskyi, Y., Naumenko, M. (2022). Automated balancing method of vector Illustration and its software implementation. Bulletin of the Transilvania University of Brasov. Series III: Mathematics and Computer Science, 2 (1), 177–192. doi: https://doi.org/10.31926/but.mif.2022.2.64.1.12 https://doi.org/10.31926/but.mif.2022.2.64.1.12

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Yevhen Hrabovskyi, Sergii Minukhin, Natalia Brynza

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.