Enhancing mechanical characteristics by adding nanoparticles and employing lasers in heat treatment

DOI:

https://doi.org/10.15587/1729-4061.2022.269127Keywords:

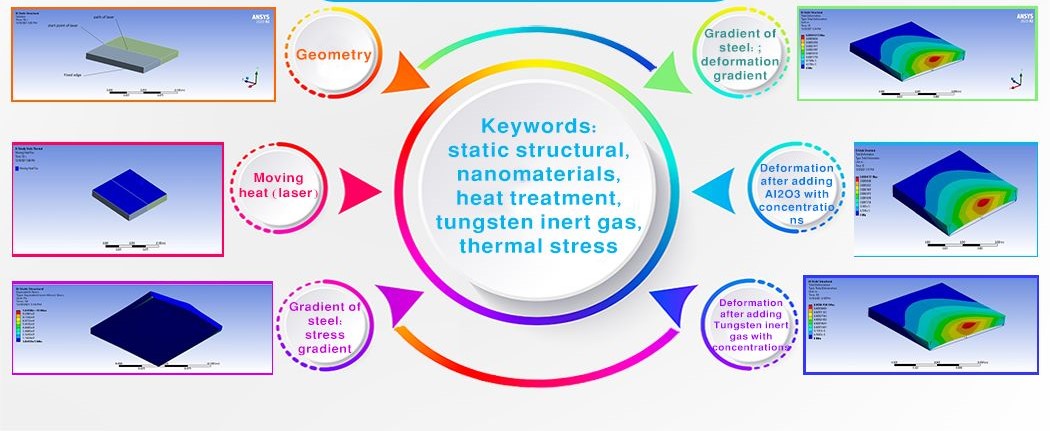

static structural, nanomaterials, heat treatment, tungsten inert gas, thermal stressAbstract

With the development of laser technology in various fields of engineering and manufacturing in terms of many uses in these areas and in the field of improving the mechanical properties of different metals for their ability to withstand different thermal and mechanical stresses and stresses. Wherein this research paper the addition of nanomaterials and laser heat shedding on them and knowing their ability to improve. The design process of the simple model that complies with the requirements of the simulation process was in the solid works program. The investigated dimensions were (100×100×10) mm3 in height, split up in the form of two portions. The partition itself is the path of the laser used. It is necessary to check the reliability of the mesh to form an appropriate mesh that can give accurate results. The nanoparticles where Al2O3 and TIC were used in different proportions with the base material. Which is steel, where these ratios were (0.3, 0.6, 1) wt %, where the results proved the process of adding nanomaterials has positive effects in terms of the materials' tolerance to heat, mechanical stress, and the surrounding conditions. Seen through the results with the increase in the concentration values of adding nanoparticles, get a significant effect on the results and the values of thermal and mechanical properties. The TIG (Tungsten inert gas) nanomaterial led to an increase in temperatures in the solid by 1 wt % compared to the rest of the concentrations and nanomaterials. The addition of nanomaterials in heat treatments has a positive effect on the amount of deformation, as the lowest value of deformation was obtained in nanomaterials at tic1 wt % compared to the rest of the concentrations. As for the stresses, the largest stress obtained is 10.502 Gpa

References

- D’Urso, L., Nicolosi, V., Compagnini, G., Puglisi, O. (2004). Size distribution of silver nanoclusters induced by ion, electron, laser beams and thermal treatments of an organometallic precursor. Applied Surface Science, 226 (1-3), 131–136. doi: https://doi.org/10.1016/j.apsusc.2003.11.012

- Badini, C., Pavese, M., Fino, P., Biamino, S. (2009). Laser beam welding of dissimilar aluminium alloys of 2000 and 7000 series: effect of post-welding thermal treatments on T joint strength. Science and Technology of Welding and Joining, 14 (6), 484–492. doi: https://doi.org/10.1179/136217108x372559

- Padovano, E., Badini, C., Pantarelli, A., Gili, F., D’Aiuto, F. (2020). A comparative study of the effects of thermal treatments on AlSi10Mg produced by laser powder bed fusion. Journal of Alloys and Compounds, 831, 154822. doi: https://doi.org/10.1016/j.jallcom.2020.154822

- Sanz, C., García Navas, V. (2013). Structural integrity of direct metal laser sintered parts subjected to thermal and finishing treatments. Journal of Materials Processing Technology, 213 (12), 2126–2136. doi: https://doi.org/10.1016/j.jmatprotec.2013.06.013

- Van den Eynde, M., Strobbe, D., Verkinderen, O., Verbelen, L., Goderis, B., Kruth, J.-P., Van Puyvelde, P. (2018). Effect of thermal treatments on the laser sinterability of cryogenically milled polybutene-1. Materials & Design, 153, 15–23. doi: https://doi.org/10.1016/j.matdes.2018.04.072

- Delgado, T., Nieto, D., Flores-Arias, M. T. (2015). Fabrication of microlens arrays on soda-lime glass using a laser direct-write technique and a thermal treatment assisted by a CO2 laser. Optics and Lasers in Engineering, 73, 1–6. doi: https://doi.org/10.1016/j.optlaseng.2015.03.026

- DiBernardo, B. E., Reyes, J., Chen, B. (2009). Evaluation of tissue thermal effects from 1064/1320-nm laser-assisted lipolysis and its clinical implications. Journal of Cosmetic and Laser Therapy, 11 (2), 62–69. doi: https://doi.org/10.1080/14764170902792181

- Haedersdal, M., Moreau, K. E. R., Beyer, D. M., Nymann, P., Alsbjørn, B. (2009). Fractional nonablative 1540 nm laser resurfacing for thermal burn scars: A randomized controlled trial. Lasers in Surgery and Medicine, 41 (3), 189–195. doi: https://doi.org/10.1002/lsm.20756

- Aboshi, A., Kurumoto, N., Yamada, T., Uchino, T. (2007). Influence of Thermal Treatments on the Photoluminescence Characteristics of Nanometer-Sized Amorphous Silica Particles. The Journal of Physical Chemistry C, 111 (24), 8483–8488. doi: https://doi.org/10.1021/jp0718505

- Mazzera, M., Zha, M., Calestani, D., Zappettini, A., Lazzarini, L., Salviati, G., Zanotti, L. (2007). Low-temperature In2O3nanowire luminescence properties as a function of oxidizing thermal treatments. Nanotechnology, 18 (35), 355707. doi: https://doi.org/10.1088/0957-4484/18/35/355707

- Stepanov, A. L., Hole, D. E., Townsend, P. D. (1999). Modification of size distribution of ion implanted silver nanoparticles in sodium silicate glass using laser and thermal annealing. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 149 (1-2), 89–98. doi: https://doi.org/10.1016/s0168-583x(98)90733-9

- Ropyak, L., Schuliar, I., Bohachenko, O. (2016). Influence of technological parameters of centrifugal reinforcement upon quality indicators of parts. Eastern-European Journal of Enterprise Technologies, 1 (5 (79)), 53–62. doi: https://doi.org/10.15587/1729-4061.2016.59850

- Kasenov, S., Askerbekova, J., Tleulesova, A. (2022). Algorithm construction and numerical solution based on the gradient method of one inverse problem for the acoustics equation. Eastern-European Journal of Enterprise Technologies, 2 (5 (116)), 43–52. doi: https://doi.org/10.15587/1729-4061.2022.253568

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Lamyaa Mahdi Asaad, Iqbal Alshalal, Faten N. Al Zubaidi, Muna Khalil Asmail

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.