Identifying factors affecting comfort workwear for mountain tourism

DOI:

https://doi.org/10.15587/1729-4061.2023.272741Keywords:

mountain tourism, pack of materials, clothes, fatigue wear, wear resistance of clothes, underwear space, heat-shielding functions of clothesAbstract

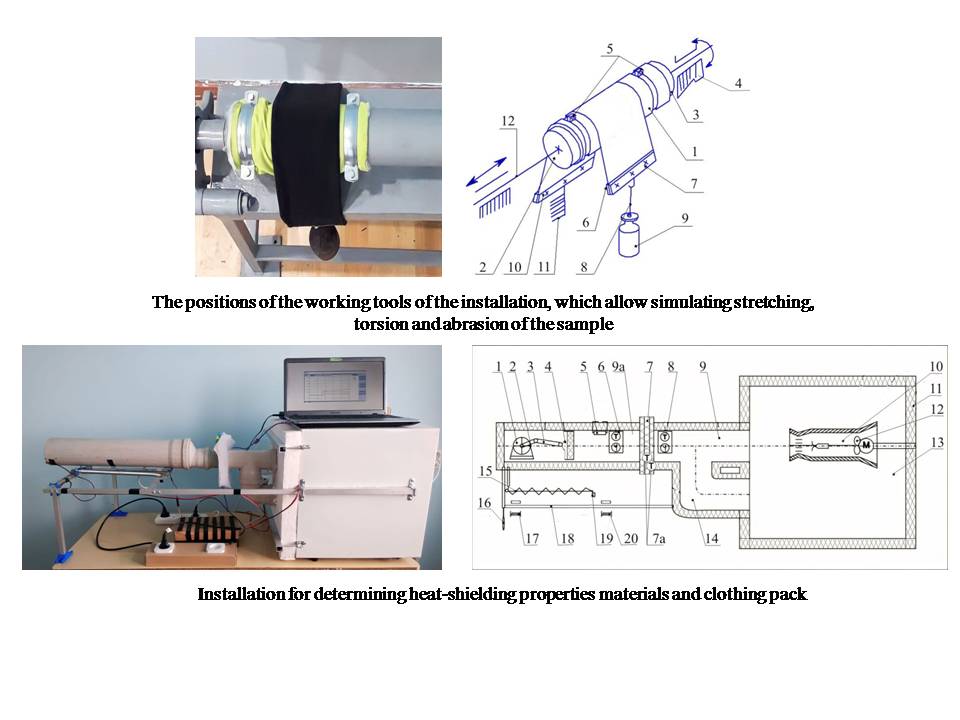

The quality and comfort of clothing for people engaged in mountain tourism are influenced by the pack of clothing materials, which determine their durability and heat resistance. In practice, wear resistance and thermal insulation of clothing materials are evaluated by standard methods for single-layer materials. To solve the problem of studying the wear resistance and heat resistance of a clothing pack, we developed an experimental setup for studying the wear resistance of the clothing pack under the influence of cyclic loads and an installation for determining the heat-shielding properties of the pack of clothing materials, allowing you to reproduce both the temperature of the underwear space, as well as environmental factors.

By studying the influence of wind flow, humidity and ambient temperature on the heat-shielding ability of packages of various compositions, the most rational package of clothing for mountain tourism was determined. The selected package provides a comfortable state of a person in the absence of air permeability and at a wind speed of 5 m/s; and at wind speeds of 10 m/s and 15 m/s, the temperature of the underwear space decreases. The heat protection of the clothing package is influenced by the breathing of the athlete’s body during movements. So, at ambient temperature Tok=20 °C and humidity within 60‒70 % when the breathing simulator was turned on in the underwear space, Tpp=26 °C, W=62 %, and when it was turned off, Tpp=27 °C, and the humidity value did not change.

The developed experimental installations and research methods can be recommended for use at the design stage in the production laboratories of enterprises producing mountain sports clothing

Supporting Agency

- The authors express their gratitude to the supervisor Usenbekov Zh. and Professor Amandykova D.A. for valuable advice in planning the study and recommendations for the design of the article.

References

- Wan, X., Wang, F., Udayraj. (2018). Numerical analysis of cooling effect of hybrid cooling clothing incorporated with phase change material (PCM) packs and air ventilation fans. International Journal of Heat and Mass Transfer, 126, 636–648. doi: https://doi.org/10.1016/j.ijheatmasstransfer.2018.05.155

- Pinto, R., Carr, D., Helliker, M., Girvan, L., Gridley, N. (2012). Degradation of military body armor due to wear: Laboratory testing. Textile Research Journal, 82 (11), 1157–1163. doi: https://doi.org/10.1177/0040517511435010

- Ke, Y., Zheng, Q., Wang, F., Wang, M., Wang, Y. (2022). High-Performance Workwear for Coal Miners in Northern China: Design and Performance Evaluation. Autex Research Journal, 22 (2), 155–162. doi: https://doi.org/10.2478/aut-2021-0020

- Zheng, Q., Ke, Y., Wang, H. (2020). Design and evaluation of cooling workwear for miners in hot underground mines using PCMs with different temperatures. International Journal of Occupational Safety and Ergonomics, 28 (1), 118–128. doi: https://doi.org/10.1080/10803548.2020.1730618

- Mandal, S., Mazumder, N.-U.-S., Agnew, R. J., Song, G., Li, R. (2021). Characterization and Modeling of Thermal Protective and Thermo-Physiological Comfort Performance of Polymeric Textile Materials – A Review. Materials, 14 (9), 2397. doi: https://doi.org/10.3390/ma14092397

- Shah, M. A., Pirzada, B. M., Price, G., Shibiru, A. L., Qurashi, A. (2022). Applications of nanotechnology in smart textile industry: A critical review. Journal of Advanced Research, 38, 55–75. doi: https://doi.org/10.1016/j.jare.2022.01.008

- Chen, B. (2021). Simulation of heat transfer process of thermal protective clothing based on FPGA and sensor processing system. Microprocessors and Microsystems, 81, 103672. doi: https://doi.org/10.1016/j.micpro.2020.103672

- Lauronen, S., Mäkinen, M., Annila, P., Huhtala, H., Yli‐Hankala, A., Kalliomäki, M. (2020). Thermal suit connected to a forced‐air warming unit for preventing intraoperative hypothermia: A randomised controlled trial. Acta Anaesthesiologica Scandinavica, 65 (2), 176–181. doi: https://doi.org/10.1111/aas.13714

- Fonseca, A., Neves, S. F., Campos, J. B. L. M. (2021). Thermal performance of a PCM firefighting suit considering transient periods of fire exposure, post – fire exposure and resting phases. Applied Thermal Engineering, 182, 115769. doi: https://doi.org/10.1016/j.applthermaleng.2020.115769

- Grave, M. F. (2004). A modelagem sob a ótica da ergonomia. São Paulo: Zennex.

- Neves, É. P. das, Brigatto, A. C., Paschoarelli, L. C. (2015). Fashion and Ergonomic Design: Aspects that Influence the Perception of Clothing Usability. Procedia Manufacturing, 3, 6133–6139. doi: https://doi.org/10.1016/j.promfg.2015.07.769

- Pezzolo, D. B. (2009). Por dentro da moda: definições e experiências. São Paulo: EditoraSenac, 224.

- Baudot, F. (2002). A moda do seculo. São Paulo: CosacNaify.

- Gorshkov, S. M. (Ed.) (1979). Industrial ergonomics. Moscow: Medicine, 334.

- Mishra, P., Pandey, C., Singh, U., Gupta, A. (2018). Scales of measurement and presentation of statistical data. Annals of Cardiac Anaesthesia, 21 (4), 419. doi: https://doi.org/10.4103/aca.aca_131_18

- ASTM D3181-15 (2019). Standard Guide for Conducting Wear Tests on Textiles. ASTM International.

- Buzov, B. A., Alymenkov, N. D. (2004). Material science in the production of light industry products (clothing industry). Moscow: Ed. Center "Academy", 448.

- Pavlov, M. A. (2018). Development and research of complex materials for clothing operated in extreme conditions. Moscow.

- Akhmedova, Z. M., Tashpulatov, S. Sh., Cherunova, I. V. (2019). Determination of the weightiness of quality indicators of textile materials and pack for heat-protective clothing. Young scientist, 52 (290), 17–19. Available at: https://moluch.ru/archive/290/65783/

- ISO 6942:2002 (2022). Protective clothing – protection against heat and fire – method of test: evaluation of materials and material assemblies when exposed to a source of radiant heat. Available at: https://infostore.saiglobal.com/en-gb/standards/iso-6942-2002-r2015--582845_saig_iso_iso_1334360

- ISO 13506-1:2017. Protective clothing against heat and flame – part 1: Test method for complete garments – measurement of transferred energy using an instrumented manikin. SAI Global. Available at: https://infostore.saiglobal.com/en-au/Standards/IS-EN-ISO-13506-1-2017-880631_SAIG_NSAI_NSAI_2092089

- ASTM D1388 (2018). Standard Test Method for Stiffness of Fabrics. ASTM International (ASTM). Available at: https://global.ihs.com/doc_detail.cfm?document_name=ASTM%20D1388&item_s_key=00015710

- ASTM D3393 (2022). Standard Specification for Coated Fabrics – Waterproofness. Available at: https://global.ihs.com/doc_detail.cfm?document_name=ASTM%20D3393&item_s_key=00017564

- ASTM D1777-96 (2019). Standard Test Method for Thickness of Textile Materials. Available at: https://webstore.ansi.org/standards/astm/astmd1777962019

- ASTM D2654-22 (2022). Standard Test Methods for Moisture in Textiles. European Standard. Available at: https://www.en-standard.eu/astm-d2654-22-standard-test-methods-for-moisture-in-textiles/?gclid=CjwKCAiAoL6eBhA3EiwAXDom5qMoa_6zvKikWDOB_up1CYRetl9uHzkT_yLxbnzUl1m0TNT9mivywRoCnBUQAvD_BwE

- ISO 20158:2018. Textiles - Determination of water absorption time and water absorption capacity of textile fabrics. Available at: https://www.iso.org/standard/69098.html

- Usenbekov, Zh., Nurbay, S. K., Ashimova, E. A. (2017). Investigation of the properties of a pack of winter clothing for athletes. Izv. universities. Technology of the textile industry, 4 (370), 200–202.

- Nurbay, S. K., Usenbekov, Zh., Lopandina, S. K., Kanatuly, A. (2019). Pat. No. 4202 KZ. Method for studying the wear resistance of pack of clothing materials and a device for its implementation. declareted: 03.06.2019.

- Shershneva, L. P., Larkina, L. V. (2023). Designing clothes. Theory and practice. Tutorial. Mosocw: Forum, 288.

- Rozanova, E. A., Moskalenko, N. G., Nomokonova, N. N. (2013). Development of structural indicators of the quality clothing for extreme sports. Modern problems of science and education, 6, 218. Available at: https://science-education.ru/en/article/view?id=11815

- Sokolova, A. S., Kuznetsov, A. A., Nadezhnaya, N. L. (2016). Method for assessing the heat-shielding properties of clothing materials and their pack. Bulletin of the Vitebsk State Technological University, 2 (31) 27, 24–31.

- Cherunova, I., Samarbaksch, S., Kornev, N. (2016). CFD simulation of thermo- aerodynamic interaction in a system human-cloth-environment under very low temperature and wind conditions. Proceedings of the VII European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS Congress 2016). doi: https://doi.org/10.7712/100016.2366.10854

- Dell, P. A., Afanas'eva, R. F., Chubarova, Z. S. (1991). Hygiene of clothes. Moscow: Legprombytizdat, 160.

- Climate of the Zailiysky Alatau. Available at: https://silkadv.com/en/content/klimat-zailiyskogo-alatau

- ASTM F1060-18 (2018). Standard Test Method for Evaluation of Conductive and Compressive Heat Resistance (CCHR). Available at: https://www.en-standard.eu/astm-f1060-18-standard-test-method-for-evaluation-of-conductive-and-compressive-heat-resistance-cchr/?gclid=CjwKCAiAoL6eBhA3EiwAXDom5rU78RtGbJFdUv_7QGu6UVYxhPB7M4xS-Ali1sVb-wCUtjCSkQm01RoC8PUQAvD_BwE

- ASTM D737-18. Standard Test Method for Air Permeability of Textile Fabrics. Available at: https://webstore.ansi.org/standards/astm/astmd73718

- Chon, K. H., Dash, S., Ju, K. (2009). Estimation of Respiratory Rate From Photoplethysmogram Data Using Time–Frequency Spectral Estimation. IEEE Transactions on Biomedical Engineering, 56 (8), 2054–2063. doi: https://doi.org/10.1109/tbme.2009.2019766

- Karlen, W., Raman, S., Ansermino, J. M., Dumont, G. A. (2013). Multiparameter Respiratory Rate Estimation From the Photoplethysmogram. IEEE Transactions on Biomedical Engineering, 60 (7), 1946–1953. doi: https://doi.org/10.1109/tbme.2013.2246160

- Nurbay, S. K., Lopandin, S. K., Usenbekov, Zh. (2019). Pat. No. 3237 KZ. Men's suit from a jacket and semi-overalls for extreme conditions. declareted: 07.12.2019; published: 07.07.2020.

- Nurbay, S. K., Lopandin, S. K., Usenbekov, Zh. (2019). Pat. No. 3236 KZ. Women's suit from a jacket and semi-overalls for extreme sports. declareted: 07.12.2019; published: 07.07.2020.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Saule Nurbay, Zhaksybek Usenbekov, Bulat Seitov, Lazzat Sarttarova, Nazima Seitova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.