Identifying some regularities of the fatigue behavior of the reinforced carbon-fiber with Al2O3 nanoparticles composite structure of the prosthesis foot

DOI:

https://doi.org/10.15587/1729-4061.2023.274573Keywords:

fatigue behavior, dynamic load, prosthesis foot, numerical analysis, life predictionAbstract

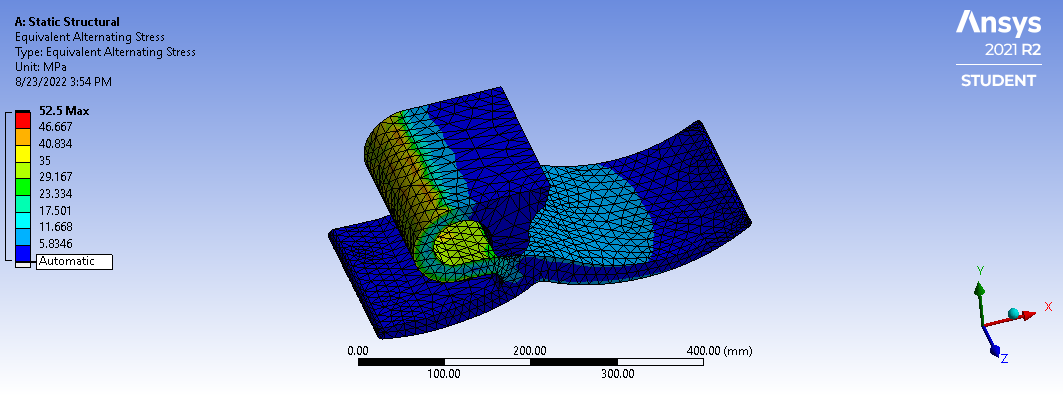

In this research Carbon-Fiber with AL2O3 Nanoparticles Composite Structure of the Prosthesis foot has been examined and analysed numerically explain the fatigue behaviour of the prosthesis. Nanoparticles made of AL2O3 were incorporated into the production process of the composite structure of the prosthesis foot in the appropriate manner. The life forecast, the damage indicator, and the Biaxiliray indexation were the three primary considerations that went into the process of studying the composite construction of the prosthesis foot. The life prediction was the most important factor. Experiments on the phenomena of fatigue have been carried out with the stress being entirely reversed as the variable in order to ensure that the findings are in keeping with the theory that was proposed by GoodMan. In order to develop an estimate for these characteristics, the dynamic load that was applied, which was 1000 N, was utilised. It used the dynamic load that was applied in order to produce an estimate for these characteristics so that we could better understand them. The results of the computational research showed that the life prediction could be increased to 106 cycles by applying a primary force of 1000 N. This was shown by the findings of the studyThis was demonstrated by the findings. While the same load application was being carried out, the Biaxiliray indexation attained a value of 0.99. In addition to the research that was done on the damage indicator, the numerical findings demonstrated that the damage can be seen after the initial 1000 cycles of stress have been applied. This was demonstrated both by the research that was done on the damage indicator as well as by the numerical findings

References

- Shen, W. (2021). Characteristics study of carbon fibre material for BioApps RoMicP® foot prosthesis. Universiti Malaya. Available at: http://studentsrepo.um.edu.my/13131/

- Jeryo, A. H., Chiad, J. S., Abbod, W. S. (2021). Boosting Mechanical Properties of Orthoses - Foot Ankle by Adding Carbon Nanotube Particles. Materials Science Forum, 1039, 518–536. doi: https://doi.org/10.4028/www.scientific.net/msf.1039.518

- Kadhim, A. A., Abbod, E. A., Muhammad, A. K., Resan, K. K., Al-Waily, M. (2021). Manufacturing and analyzing of a new prosthetic shank with adapters by 3D printer. Journal of Mechanical Engineering Research and Developments, 44 (3), 383–391. Available at: https://jmerd.net/Paper/Vol.44,No.3(2021)/383-391.pdf

- Kumar, S., Bhowmik, S. (2022). Potential use of natural fiber-reinforced polymer biocomposites in knee prostheses: a review on fair inclusion in amputees. Iranian Polymer Journal, 31 (10), 1297–1319. doi: https://doi.org/10.1007/s13726-022-01077-1

- Wen, T.-C., Jacobson, M., Zhou, X., Chung, H.-J., Kim, M. (2020). The personalization of stiffness for an ankle-foot prosthesis emulator using Human-in-the-loop optimization. 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). doi: https://doi.org/10.1109/iros45743.2020.9341101

- Blaya Haro, F., D’Amato, R., Luján González, A., Blaya San Pedro, A., Nuere, S. (2020). Analysis Method for The Design and Manufacture of Sports Transtibial Prostheses. Eighth International Conference on Technological Ecosystems for Enhancing Multiculturality. doi: https://doi.org/10.1145/3434780.3436632

- Ismawan, A. R., Ismail, R., Prahasto, T., Ariyanto, M., Setiyana, B. (2022). A Review of Existing Transtibial Bionic Prosthesis: Mechanical Design, Actuators and Power Transmission. Journal of Biomedical Science and Bioengineering, 1 (2), 65–72. doi: https://doi.org/10.14710/jbiomes.2021.v1i2.65-72

- Chergui, K., Ameddah, H., Mazouz, H. (2018). Biomechanical analysis of fatigue behavior of a fully composite-based designed hip resurfacing prosthesis. Journal of the Serbian Society for Computational Mechanics, 12 (2), 80–94. doi: https://doi.org/10.24874/jsscm.2018.12.02.06

- Deng, L., Barton, B., Lorenzo, J., Rashid, H., Dastouri, F., Booy, R. (2021). Longer term outcomes following serogroup B invasive meningococcal disease. Journal of Paediatrics and Child Health, 57 (6), 894–902. doi: https://doi.org/10.1111/jpc.15350

- Akhtar, S., Saad, M., Pandey, P. (2018). Overview of Current Advances in The Development of Polymer Composite in Biomedical Applications. Materials Today: Proceedings, 5 (9), 20217–20223. doi: https://doi.org/10.1016/j.matpr.2018.06.392

- Tabucol, J., Kooiman, V. G. M., Leopaldi, M., Brugo, T. M., Leijendekkers, R. A., Tagliabue, G. et al. (2022). The Functionality Verification through Pilot Human Subject Testing of MyFlex-δ: An ESR Foot Prosthesis with Spherical Ankle Joint. Applied Sciences, 12 (9), 4575. doi: https://doi.org/10.3390/app12094575

- Saad, M., Akhtar, S., Srivastava, S. (2018). Composite Polymer in Orthopedic Implants: A Review. Materials Today: Proceedings, 5 (9), 20224–20231. doi: https://doi.org/10.1016/j.matpr.2018.06.393

- Alimi, L., Menail, Y., Chaoui, K., Kechout, K., Mabrouk, S., Zeghib, N. et al. (2020). Mechanical Strength Analysis and Damage Appraisal in Carbon/Perlon/Epoxy Composite for Orthopedic Prostheses. Proceedings of the 4th International Symposium on Materials and Sustainable Development, 23–33. doi: https://doi.org/10.1007/978-3-030-43211-9_3

- Tabernero, A., González-Garcinuño, Á., Cardea, S., Martín del Valle, E. (2022). Supercritical carbon dioxide and biomedicine: Opening the doors towards biocompatibility. Chemical Engineering Journal, 444, 136615. doi: https://doi.org/10.1016/j.cej.2022.136615

- McGeehan, M. A., Karipott, S. S., Hahn, M. E., Morgenroth, D. C., Ong, K. G. (2021). An Optoelectronics-Based Sensor for Measuring Multi-Axial Shear Stresses. IEEE Sensors Journal, 21 (22), 25641–25648. doi: https://doi.org/10.1109/jsen.2021.3117935

- Corro, H., Vidal Lesso, A., Ledesma Orozco, E. R., Palacios Pineda, L. M. (2020). Structural analysis of a new total ankle replacement prosthesis with internal structure. DYNA, 95 (1), 192–197. doi: https://doi.org/10.6036/9267

- Acosta-Sánchez, L. A., Botello-Arredondo, A. I., Moya-Bencomo, M. D., Zúñiga-Aguilar, E. S. (2020). Porous lattice structure of femoral stem for total Hip arthroplasty. Revista mexicana de ingeniería biomédica, 41 (1), 69–79. doi: ttps://doi.org/10.17488/rmib.41.1.5

- Ghosh, U., Ning, S., Wang, Y., Kong, Y. L. (2018). Addressing Unmet Clinical Needs with 3D Printing Technologies. Advanced Healthcare Materials, 7 (17), 1800417. doi: https://doi.org/10.1002/adhm.201800417

- Summers, S. H., Zachwieja, E. C., Butler, A. J., Mohile, N. V., Pretell-Mazzini, J. (2019). Proximal Tibial Reconstruction After Tumor Resection. JBJS Reviews, 7 (7), e1–e1. doi: https://doi.org/10.2106/jbjs.rvw.18.00146

- Mu, M. duo, Yang, Q. dong, Chen, W., Tao, X., Zhang, C. ke, Zhang, X. et al. (2021). Three dimension printing talar prostheses for total replacement in talar necrosis and collapse. International Orthopaedics, 45 (9), 2313–2321. doi: https://doi.org/10.1007/s00264-021-04992-9

- Manuel Javier, R. S., Dávalos Ramírez, J. O., Molina Salazar, J., Ruiz Ochoa, J. A., Gómez Roa, A. (2021). Optimization of Running Blade Prosthetics Utilizing Crow Search Algorithm Assisted by Artificial Neural Networks. Strojniški Vestnik – Journal of Mechanical Engineering, 67 (3), 88–100. doi: https://doi.org/10.5545/sv-jme.2020.6990

- Liza, S., Shahemi, N. H., Yee, T. M., Khadijah Syed, S., Puad, M. (2021). Biomedical Tribology. Tribology and Sustainability, 353–377. doi: https://doi.org/10.1201/9781003092162-23

- Bello, S. A., Kolawole, M. Y. (2020). Recycled Plastics and Nanoparticles for Green Production of Nano Structural Materials. Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications, 1–33. doi: https://doi.org/10.1007/978-3-030-11155-7_93-1

- Estay, D., Basoalto, A., Ardila, J., Cerda, M., Barraza, R. (2021). Development and Implementation of an Anthropomorphic Underactuated Prosthesis with Adaptive Grip. Machines, 9 (10), 209. doi: https://doi.org/10.3390/machines9100209

- Carty, M. J., Herr, H. M. (2021). The Agonist-Antagonist Myoneural Interface. Hand Clinics, 37 (3), 435–445. doi: https://doi.org/10.1016/j.hcl.2021.04.006

- Bermudez, D. A., Avitia, R. L., Reyna, M. A., Camarillo, M. A., Bravo, M. E. (2022). Energy expenditure in lower limb amputees with prosthesis. 2022 Global Medical Engineering Physics Exchanges/ Pan American Health Care Exchanges (GMEPE/PAHCE). doi: https://doi.org/10.1109/gmepe/pahce55115.2022.9757804

- Whitehead, K. A., El Mohtadi, M., Slate, A. J., Vaidya, M., Wilson-Nieuwenhuis, J. (2021). The Effects of Surface Properties on the Antimicrobial Activity and Biotoxicity of Metal Biomaterials and Coatings. The Chemistry of Inorganic Biomaterials, 231–289. doi: https://doi.org/10.1039/9781788019828-00231

- Lee, I.-C., Fylstra, B. L., Liu, M., Lenzi, T., Huang, H. (2022). Is there a trade-off between economy and task goal variability in transfemoral amputee gait? Journal of NeuroEngineering and Rehabilitation, 19 (1). doi: https://doi.org/10.1186/s12984-022-01004-8

- Russell, C., Roche, A. D., Chakrabarty, S. (2019). Peripheral nerve bionic interface: a review of electrodes. International Journal of Intelligent Robotics and Applications, 3 (1), 11–18. doi: https://doi.org/10.1007/s41315-019-00086-3

- Zafar, M. S. (2020). Prosthodontic Applications of Polymethyl Methacrylate (PMMA): An Update. Polymers, 12 (10), 2299. https://doi.org/10.3390/polym12102299

- Ahmed, W., Siraj, S., Alnajjar, F., Al Marzouqi, A. H. (2021). 3D Printed Implants for Joint Replacement. Applications of 3D Printing in Biomedical Engineering, 97–119. doi: https://doi.org/10.1007/978-981-33-6888-0_4

- Nair, V. S., Nachimuthu, R. (2022). The role of NiTi shape memory alloys in quality of life improvement through medical advancements: A comprehensive review. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, 236 (7), 923–950. doi: https://doi.org/10.1177/09544119221093460

- Nykyforov, А., Antoshchenkov, R., Halych, I., Kis, V., Polyansky, P., Koshulko, V. et al. (2022). Construction of a regression model for assessing the efficiency of separation of lightweight seeds on vibratory machines involving measures to reduce the harmful influence of the aerodynamic factor. Eastern-European Journal of Enterprise Technologies, 2 (1 (116)), 24–34. doi: https://doi.org/10.15587/1729-4061.2022.253657

- Khudov, H., Makoveichuk, O., Misiuk, D., Pievtsov, H., Khizhnyak, I., Solomonenko, Y. et al. (2022). Devising a method for processing the image of a vehicle’s license plate when shooting with a smartphone camera. Eastern-European Journal of Enterprise Technologies, 1 (2 (115)), 6–21. doi: https://doi.org/10.15587/1729-4061.2022.252310

- Kovalchuk, V., Sobolevska, Y., Onyshchenko, A., Bal, O., Kravets, I., Pentsak, A. et al. (2022). Investigating the influence of the diameter of a fiberglass pipe on the deformed state of railroad transportation structure “embankment-pipe.” Eastern-European Journal of Enterprise Technologies, 2 (7 (116)), 35–43. doi: https://doi.org/10.15587/1729-4061.2022.254573

- Sharaf, H. K., Ishak, M. R., Sapuan, S. M., Yidris, N. (2020). Conceptual design of the cross-arm for the application in the transmission towers by using TRIZ–morphological chart–ANP methods. Journal of Materials Research and Technology, 9 (4), 9182–9188. doi: https://doi.org/10.1016/j.jmrt.2020.05.129

- Sharaf, H. K., Ishak, M. R., Sapuan, S. M., Yidris, N., Fattahi, A. (2020). Experimental and numerical investigation of the mechanical behavior of full-scale wooden cross arm in the transmission towers in terms of load-deflection test. Journal of Materials Research and Technology, 9 (4), 7937–7946. doi: https://doi.org/10.1016/j.jmrt.2020.04.069

- Sharaf, H. K., Salman, S., Abdulateef, M. H., Magizov, R. R., Troitskii, V. I., Mahmoud, Z. H. et al. (2021). Role of initial stored energy on hydrogen microalloying of ZrCoAl(Nb) bulk metallic glasses. Applied Physics A, 127 (1). doi: https://doi.org/10.1007/s00339-020-04191-0

- Noori Hamzah, M., Abdulhessen Gatta, A. (2019). Dorsiflexion and Plantarflexion Test and Analysis for a new Carbon Fiber Ankle-Foot Prosthesis. University of Thi-Qar Journal for Engineering Sciences. doi: https://doi.org/10.31663/tqujes.10.1.355(2019)

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ali Talib Shomran, Batool Mardan Faisal, Emad Kamil Hussein, Thiago Santos, Kies Fatima

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.