Hierarchic change system dynamics supply chain model: impact of demand information sharing on holding cost and downstream project completion

DOI:

https://doi.org/10.15587/1729-4061.2023.269284Keywords:

downstream project completion, multi-echelon supply chain, demand information sharing, system dynamics, andesite aggregate stoneAbstract

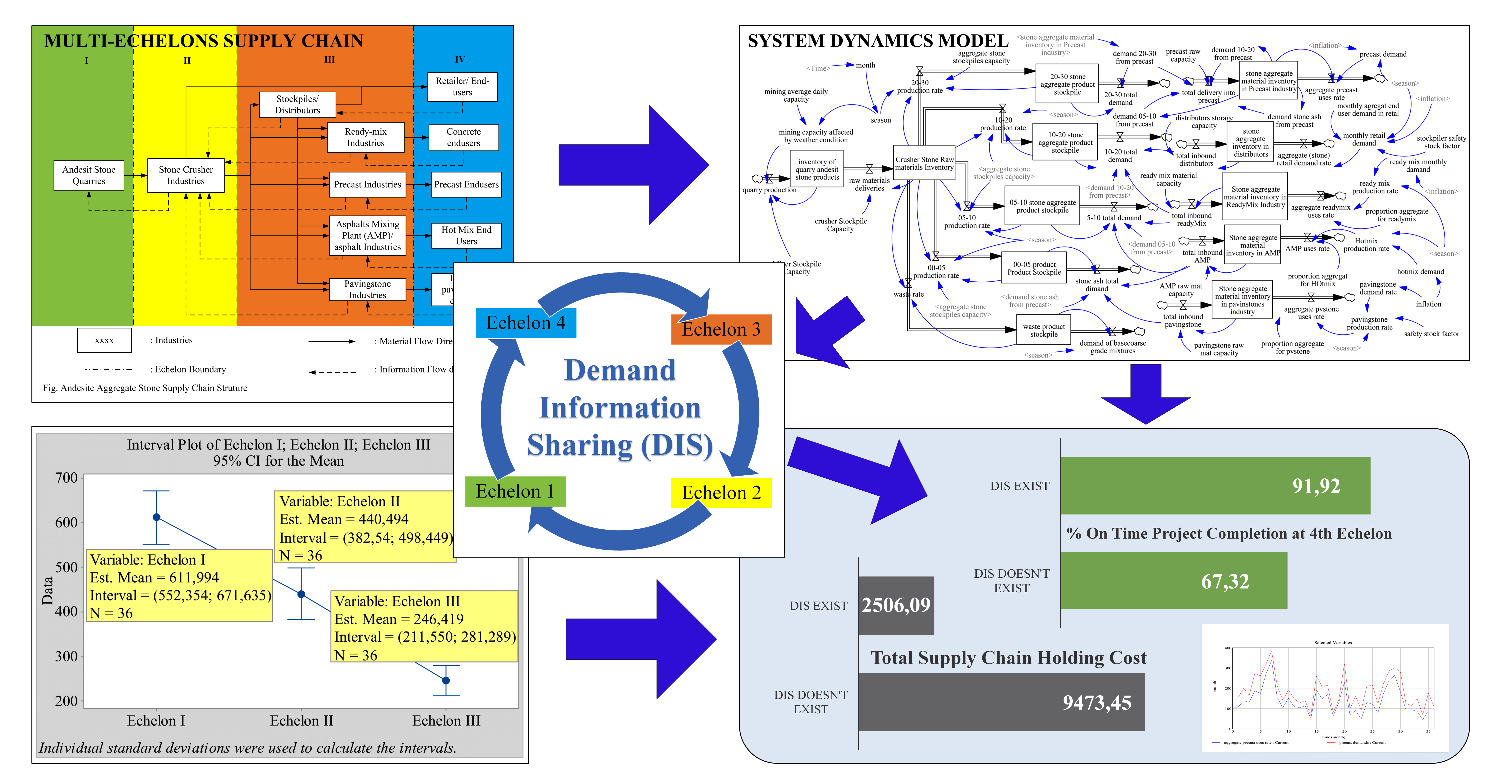

The interrelationships between system components are critical to improving the performance of a complex supply chain system. Thus, any improvement or development can be carried out systemically and comprehensively. The complexity of coordination grows as the number of echelons in a supply chain increases. In practice, coordination becomes more difficult to implement in a supply chain with more echelons. Through demand information sharing, this research attempts to figure out how coordination can have implications for complex multi-echelon supply chains with a modeling approach. The Aggregate Andesite Stone Supply Chain is used as an empirical model with four echelons. Changes in dimensions and values per ton of product in each echelon displacement add complexity. Total holding cost is not the only consideration. The timely completion of projects downstream is also a priority. So the system's behavior that runs and changes over time also needs to be observed. To accommodate this complexity, a system dynamics modeling approach is used. This modeling technique could capture fluctuations in volatile conditions that change in time sequences. The pattern of model behavior shows that demand information sharing in the andesite aggregate supply chain is faint, and the "bullwhip effect" occurs. The demand information sharing can eliminate this effect, reduce up to 73.5 % of total supply chain holding costs, and increase the percentage of project completion on time downstream of the supply chain. These results provide a scientific and practical understanding that although there are many obstacles, demand information sharing can significantly improve performance in multi-echelon complex supply chains and be worthwhile applied

References

- Gronwald, K.-D. (2020). SCM – Supply-Chain-Management. Integrierte Business-Informationssysteme, 25–69. doi: https://doi.org/10.1007/978-3-662-59815-3_3

- Pujawan, I. N., Mahendrawathi, E. (2017). Supply Chain Management (Edisi 3). Yogyakarta, 374.

- Kharsun, L., Kavun-Moshkovska, O., Kotova, M., Nechyporuk, A. (2022). Adaptation of risk management in the supply chains of e-commerce enterprises under the conditions of political instability. Eastern-European Journal of Enterprise Technologies, 5 (13 (119)), 6–20. doi: https://doi.org/10.15587/1729-4061.2022.265649

- Wankmüller, C., Reiner, G. (2021). Identifying Challenges and Improvement Approaches for More Efficient Procurement Coordination in Relief Supply Chains. Sustainability, 13 (4), 2204. doi: https://doi.org/10.3390/su13042204

- Li, S., Zhao, X., Huo, B. (2018). Supply chain coordination and innovativeness: A social contagion and learning perspective. International Journal of Production Economics, 205, 47–61. doi: https://doi.org/10.1016/j.ijpe.2018.07.033

- Nguyen, W. P. V., Dusadeerungsikul, P. O., Nof, S. Y. (2022). Collaborative Control, Task Administration, and Fault Tolerance for Supply Chain Network-Dynamics. Springer Series in Supply Chain Management, 43–78. doi: https://doi.org/10.1007/978-3-031-09179-7_3

- Arshinder, Kanda, A., Deshmukh, S. G. (2008). Supply chain coordination: Perspectives, empirical studies and research directions. International Journal of Production Economics, 115 (2), 316–335. doi: https://doi.org/10.1016/j.ijpe.2008.05.011

- Feizabadi, J., Gligor, D., Alibakhshi, S. (2021). Strategic supply chains: a configurational perspective. The International Journal of Logistics Management, 32 (4), 1093–1123. doi: https://doi.org/10.1108/ijlm-09-2020-0383

- Kurudzhy, Y., Mayorova, I., Moskvichenko, I. (2022). Building a model of supply chains duopoly taking into account the marketing and innovative activities of manufacturing enterprises. Eastern-European Journal of Enterprise Technologies, 2 (3 (116)), 15–21. doi: https://doi.org/10.15587/1729-4061.2022.253821

- Ren, J., Hao, Y., Liu, Y. (2010). Two-Echelon Supply Chain Coordination with Uncertain Demand. 2010 Third International Conference on Intelligent Networks and Intelligent Systems. doi: https://doi.org/10.1109/icinis.2010.79

- Du, R., Banerjee, A., Kim, S.-L. (2013). Coordination of two-echelon supply chains using wholesale price discount and credit option. International Journal of Production Economics, 143 (2), 327–334. doi: https://doi.org/10.1016/j.ijpe.2011.12.017

- Xu, Y., Wei, W. (2010). Coordinative of one-shot cooperation in two-echelon supply chain. 2010 IEEE International Conference on Software Engineering and Service Sciences. doi: https://doi.org/10.1109/icsess.2010.5552270

- Ren, J. Y., Liu, Y. X., Hao, Y. P. (2009). Two-Echelon Supply Chain Coordination with Vendor Managed Inventory. Applied Mechanics and Materials, 16-19, 1048–1052. doi: https://doi.org/10.4028/www.scientific.net/amm.16-19.1048

- Giri, B. C., Bardhan, S. (2017). Sub-supply chain coordination in a three-layer chain under demand uncertainty and random yield in production. International Journal of Production Economics, 191, 66–73. doi: https://doi.org/10.1016/j.ijpe.2017.04.012

- Seifert, R. W., Zequeira, R. I., Liao, S. (2012). A three-echelon supply chain with price-only contracts and sub-supply chain coordination. International Journal of Production Economics, 138 (2), 345–353. doi: https://doi.org/10.1016/j.ijpe.2012.04.006

- Yu, Z., Zu, S. (2011). Three-echelon supply chain coordination model based on option-buyback contract. 2011 International Conference on E-Business and E-Government (ICEE). doi: https://doi.org/10.1109/icebeg.2011.5887240

- Shaban, A., Costantino, F., Di Gravio, G., Tronci, M. (2020). Coordinating of multi-echelon supply chains through the generalized (R, S) policy. SIMULATION, 96 (9), 767–778. doi: https://doi.org/10.1177/0037549720920708

- Abdelsalam, H. M., Elassal, M. M. (2014). Joint economic lot sizing problem for a three – Layer supply chain with stochastic demand. International Journal of Production Economics, 155, 272–283. doi: https://doi.org/10.1016/j.ijpe.2014.01.015

- Hu, J., Zhang, J., Mei, M., Yang, W. min, Shen, Q. (2019). Quality control of a four-echelon agri-food supply chain with multiple strategies. Information Processing in Agriculture, 6(4), 425–437. doi: https://doi.org/10.1016/j.inpa.2019.05.002

- Purnomo, M. R. A., Wangsa, I. D., Rizky, N., Jauhari, W. A., Zahria, I. (2022). A multi-echelon fish closed-loop supply chain network problem with carbon emission and traceability. Expert Systems with Applications, 210, 118416. doi: https://doi.org/10.1016/j.eswa.2022.118416

- Khorshidvand, B., Soleimani, H., Sibdari, S., Seyyed Esfahani, M. M. (2021). Developing a two-stage model for a sustainable closed-loop supply chain with pricing and advertising decisions. Journal of Cleaner Production, 309, 127165. doi: https://doi.org/10.1016/j.jclepro.2021.127165

- Tantiwattanakul, P., Dumrongsiri, A. (2019). Supply chain coordination using wholesale prices with multiple products, multiple periods, and multiple retailers: Bi-level optimization approach. Computers & Industrial Engineering, 131, 391–407. doi: https://doi.org/10.1016/j.cie.2019.03.050

- Haque, M., Paul, S. K., Sarker, R., Essam, D. (2021). A combined approach for modeling multi-echelon multi-period decentralized supply chain. Annals of Operations Research, 315 (2), 1665–1702. doi: https://doi.org/10.1007/s10479-021-04121-0

- Marchi, B., Zavanella, L. E., Zanoni, S. (2020). Joint economic lot size models with warehouse financing and financial contracts for hedging stocks under different coordination policies. Journal of Business Economics, 90 (8), 1147–1169. doi: https://doi.org/10.1007/s11573-020-00975-1

- Liao, C.-J., Shyu, C.-C., Tseng, C.-T. (2009). A least flexibility first heuristic to coordinate setups in a two- or three-stage supply chain. International Journal of Production Economics, 117 (1), 127–135. doi: https://doi.org/10.1016/j.ijpe.2008.10.002

- Buhayenko, V., Ho, S. C., Thorstenson, A. (2018). A variable neighborhood search heuristic for supply chain coordination using dynamic price discounts. EURO Journal on Transportation and Logistics, 7 (4), 363–385. doi: https://doi.org/10.1007/s13676-018-0122-2

- Seeler, K. A. (2014). Introduction to System Dynamics. System Dynamics, 1–44. doi: https://doi.org/10.1007/978-1-4614-9152-1_1

- Dangerfield, B. (2020). System Dynamics: Introduction. System Dynamics, 3–7. doi: https://doi.org/10.1007/978-1-4939-8790-0_538

- Breitling, T. (2019). Inter-functional coordination of purchasing and logistics: impact on supply chain performance. Supply Chain Forum: An International Journal, 20 (2), 71–88. doi: https://doi.org/10.1080/16258312.2019.1612226

- Wirjodirdjo, B., Ghiffary Budianto, A., Widjanarka, A., Pujawan, I. N., Maflahah, I. (2021). Carrier and Freight Forwarders Strategies to Utilize the Immobile Shipping Capacity of Freight Forwarders and Maximize Profits. International Journal of Technology, 12 (4), 876. doi: https://doi.org/10.14716/ijtech.v12i4.4413

- Dogan, M., Cerci, H. S., Koyluoglu, A. S. (2022). The effect of green supply chain practices on the firm performance: an empirical research. Eastern-European Journal of Enterprise Technologies, 4 (13 (118)), 61–67. doi: https://doi.org/10.15587/1729-4061.2022.263634

- Large, R. O., Merminod, N. (2019). Special Dossier: inter-functional coordination in the supply chain: myth or reality? Supply Chain Forum: An International Journal, 20 (2), 69–70. doi: https://doi.org/10.1080/16258312.2019.1609276

- Qrunfleh, S., Tarafdar, M. (2014). Supply chain information systems strategy: Impacts on supply chain performance and firm performance. International Journal of Production Economics, 147, 340–350. doi: https://doi.org/10.1016/j.ijpe.2012.09.018

- Cokins, G., Pohlen, T., Klammer, T. (2021). Why Supply Chain Cost Systems Differ from Traditional Cost Systems. Supply Chain Costing and Performance Management, 59–74. doi: https://doi.org/10.1002/9781119793663.ch5

- Iida, T. (2012). Coordination of cooperative cost-reduction efforts in a supply chain partnership. European Journal of Operational Research, 222 (2), 180–190. doi: https://doi.org/10.1016/j.ejor.2012.03.029

- Kim, M., Chai, S. (2017). The impact of supplier innovativeness, information sharing and strategic sourcing on improving supply chain agility: Global supply chain perspective. International Journal of Production Economics, 187, 42–52. doi: https://doi.org/10.1016/j.ijpe.2017.02.007

- Huang, R., Yao, X. (2021). An analysis of sustainability and channel coordination in a three-echelon supply chain. Journal of Enterprise Information Management, 34 (1), 490–505. doi: https://doi.org/10.1108/jeim-12-2019-0413

- Niemsakul, J., Islam, S. M. N., Singkarin, D., Somboonwiwat, T. (2018). Cost-benefit sharing in healthcare supply chain collaboration. International Journal of Logistics Systems and Management, 30 (3), 406. doi: https://doi.org/10.1504/ijlsm.2018.092624

- Mouaky, M., Berrado, A., Benabbou, L. (2019). Using a kanban system for multi-echelon inventory management: the case of pharmaceutical supply chains. International Journal of Logistics Systems and Management, 32 (3/4), 496. doi: https://doi.org/10.1504/ijlsm.2019.098333

- Drakaki, M., Tzionas, P. (2019). Investigating the impact of inventory inaccuracy on the bullwhip effect in RFID-enabled supply chains using colored petri nets. Journal of Modelling in Management, 14 (2), 360–384. doi: https://doi.org/10.1108/jm2-08-2017-0081

- Khedlekar, U. K., Singh, P. (2019). Three-layer supply chain policy under sharing recycling responsibility. Journal of Advances in Management Research, 16 (5), 734–762. doi: https://doi.org/10.1108/jamr-01-2019-0002

- Rached, M. (2020). Genetic Algorithm to Evaluate Downstream and Upstream Information Sharing. Current Signal Transduction Therapy, 15 (1), 24–33. doi: https://doi.org/10.2174/1574362413666180830105740

- Haque, M., Paul, S. K., Sarker, R., Essam, D. (2020). Managing decentralized supply chain using bilevel with Nash game approach. Journal of Cleaner Production, 266, 121865. doi: https://doi.org/10.1016/j.jclepro.2020.121865

- Van Belle, J., Guns, T., Verbeke, W. (2021). Using shared sell-through data to forecast wholesaler demand in multi-echelon supply chains. European Journal of Operational Research, 288 (2), 466–479. doi: https://doi.org/10.1016/j.ejor.2020.05.059

- Ibrahim, A., Daniyal, H., Asmawaty, T., Kamaludin, A. (2021). Potential Data Collections Methods for System Dynamics Modelling: A Brief Overview. International Journal of Advanced Computer Science and Applications, 12 (3). doi: https://doi.org/10.14569/ijacsa.2021.0120332

- Rebs, T., Brandenburg, M., Seuring, S. (2019). System dynamics modeling for sustainable supply chain management: A literature review and systems thinking approach. Journal of Cleaner Production, 208, 1265–1280. doi: https://doi.org/10.1016/j.jclepro.2018.10.100

- Liu, J., Teng, Y., Wang, D., Gong, E. (2019). System dynamic analysis of construction waste recycling industry chain in China. Environmental Science and Pollution Research, 27 (30), 37260–37277. doi: https://doi.org/10.1007/s11356-019-06739-x

- Sundarakani, B., Sikdar, A., Balasubramanian, S. (2014). System dynamics-based modelling and analysis of greening the construction industry supply chain. International Journal of Logistics Systems and Management, 18 (4), 517. doi: https://doi.org/10.1504/ijlsm.2014.063983

- Wang, J., Li, Z., Tam, V. W. Y. (2015). Identifying best design strategies for construction waste minimization. Journal of Cleaner Production, 92, 237–247. doi: https://doi.org/10.1016/j.jclepro.2014.12.076

- Malik, A., Khan, K. I. A., Qayyum, S., Ullah, F., Maqsoom, A. (2022). Resilient Capabilities to Tackle Supply Chain Risks: Managing Integration Complexities in Construction Projects. Buildings, 12 (9), 1322. doi: https://doi.org/10.3390/buildings12091322

- Ghufran, M., Khan, K. I. A., Ullah, F., Nasir, A. R., Al Alahmadi, A. A., Alzaed, A. N., Alwetaishi, M. (2022). Circular Economy in the Construction Industry: A Step towards Sustainable Development. Buildings, 12 (7), 1004. doi: https://doi.org/10.3390/buildings12071004

- Nasir, M. H. A., Genovese, A., Acquaye, A. A., Koh, S. C. L., Yamoah, F. (2017). Comparing linear and circular supply chains: A case study from the construction industry. International Journal of Production Economics, 183, 443–457. doi: https://doi.org/10.1016/j.ijpe.2016.06.008

- Wang, X., Du, Q., Lu, C., Li, J. (2022). Exploration in carbon emission reduction effect of low-carbon practices in prefabricated building supply chain. Journal of Cleaner Production, 368, 133153. doi: https://doi.org/10.1016/j.jclepro.2022.133153

- Yin, Y., Zhang, Y., Jin, K. (2021). System Dynamics Modeling of the Supply Chain Performance of Prefabricated Construction Based on the Stakeholder Analysis. Journal of Physics: Conference Series, 1827 (1), 012109. doi: https://doi.org/10.1088/1742-6596/1827/1/012109

- Vanteddu, G., Nicholls, G. (2020). Supply Chain Network Design and Tactical Planning in the Dimension Stone Industry. Operations and Supply Chain Management: An International Journal, 13 (4), 320–335. doi: https://doi.org/10.31387/oscm0430273

- Forrester, J. W., Collins, F. (1972). World Dynamics. Journal of Dynamic Systems, Measurement, and Control, 94 (4), 339–339. doi: https://doi.org/10.1115/1.3426619

- Forrester, J. W. (2016). Learning through System Dynamics as Preparation for the 21st Century. System Dynamics Review, 32 (3-4), 187–203. doi: https://doi.org/10.1002/sdr.1571

- Fudhlaa, A. F., Rachmawati, W., Retnowati, D. (2021). Analysis of sugar import policy effects on sugar cane farmer’s income in East Java: A system dynamic approach. IOP Conference Series: Materials Science and Engineering, 1072 (1), 012023. doi: https://doi.org/10.1088/1757-899x/1072/1/012023

- Barlas, Y. (1989). Multiple tests for validation of system dynamics type of simulation models. European Journal of Operational Research, 42 (1), 59–87. doi: https://doi.org/10.1016/0377-2217(89)90059-3

- Shreckengost, R. C. (1985). Dynamic simulation models: how valid are they? PsycEXTRA Dataset. doi: https://doi.org/10.1037/e496952006-007

- Olaya, C. (2020). System Dynamics: Engineering Roots of Model Validation. System Dynamics, 109–117. doi: https://doi.org/10.1007/978-1-4939-8790-0_544

- Ghali, A., Favre, R., Elbadry, M. (2020). Concrete Structures. CRC Press, 672. doi: https://doi.org/10.1201/9781003061274

- Nihad, Z., Sarsam, S. I. (2020). Variation of Asphalt Requirement and Strength Properties among Hot Mix (HMA) and Warm Mix (WMA) Asphalt Concrete. Association of Arab Universities Journal of Engineering Sciences, 27 (2), 24–33. doi: https://doi.org/10.33261/jaaru.2020.27.2.003

- Amin, F., Khan, K. I. A., Ullah, F., Alqurashi, M., Alsulami, B. T. (2022). Key Adoption Factors for Collaborative Technologies and Barriers to Information Management in Construction Supply Chains: A System Dynamics Approach. Buildings, 12 (6), 766. doi: https://doi.org/10.3390/buildings12060766

- Chopra, S. (2018). Supply Chain Management: Strategy, Planning, and Operation (What’s New in Operations Management). Pearson, 528.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ahmad Fatih Fudhla, Budisantoso Wirjodirdjo

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.