Analysis of compositions and fuel specifications of the aqueous emulsion fuels of gasoline (RON 90)-ethanol-water in stable emulsions at low temperatures

DOI:

https://doi.org/10.15587/1729-4061.2023.272512Keywords:

gasoline, ethanol, water in one phase, fuel parameter, stable emulsion, gasoline and aqueous ethanol dissolve, conditions of gasoline and aqueous ethanol separation, single-phase, non-synthetic surfactant emulsionAbstract

Many countries worldwide encounter the greatest difficulties in improving people's life quality since fossil fuel reserves are decreasing, causing fuel prices to rise drastically. This problem has made many countries, including Indonesia, struggle to import them from producers in the Middle East. Adding a small part of ethanol to gasoline is one of the solutions that has been investigated and developed.

The previous works relating to blended fuels, gasoline and ethanol, generally employed absolute alcohol, which was expensive. A small surfactant was added to the mixture to stabilize the emulsion, and the blending was conducted in normal conditions (room temperature). If the composition of gasoline and aqueous ethanol is not precise, the components can be separated at a specific temperature.

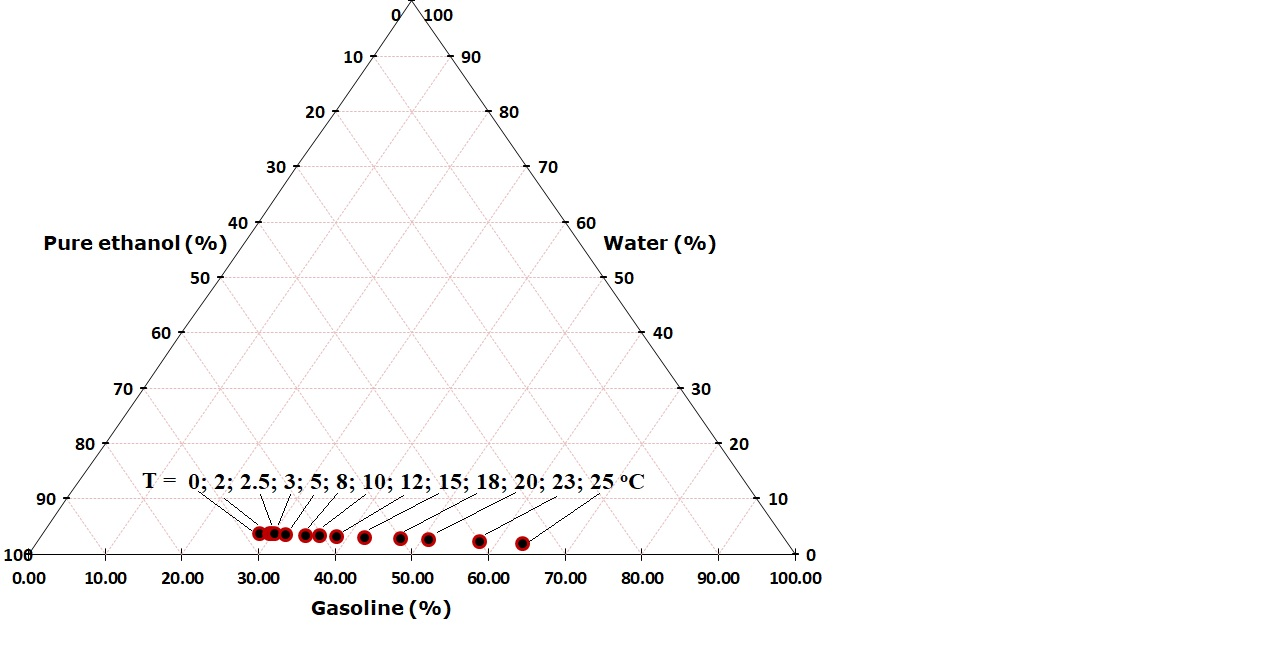

The present study is aimed to report the analysis of compositions and fuel specifications of aqueous emulsions of gasoline (RON 90)-ethanol-water in a single phase without using a synthetic surfactant in the temperature range of 0–25 °C. The procedures were as follows: fermentation, ethanol distillation and purification, cooling, blending, and characterization of fuel specifications. Components of gasoline (RON 90)-ethanol-water formed a stable emulsion in the composition range of 28.00‒99.79 %, 0.20‒67.97 %, and 0.01‒3.58 %. The observation found that continually increasing the amount of aqueous ethanol and temperature after one phase was attained would not lead to the separation of components. Therefore, gasoline and aqueous ethanol can form a single phase functioning as a surfactant binding water and fossil fuel. The decrease in temperature after the emulsion is stabilized can separate the components whereby it is caused by the faster density change of aqueous ethanol than gasoline

Supporting Agency

- The work had finished successfully under supporting of respected persons at my institution, Sam Ratulangi University, Manado, Indonesia. I thank Rector Professor Ellen Joan Kumaat, who fully supported the work by providing the Lab facility needed. Furthermore, I greatly appreciate Professor Jefrey I. Kindangen, who competitively selected the submitted project proposals and managed the research administration documents. Finally, the approval of the research proposal signed by the Dean of Mathematics and Sciences School, Professor Benny Pinontoan, is highly appreciated. We also thank the contributors, the PIC of the Laboratory of Oil and Gas Processing Engineering, Polytechnic of Energy and Minerals, Cepu Blora, Central Java, and Oil and Gas Laboratory, State Polytechnic of Samarinda, East Kalimantan. We appreciate their technical assistance in measuring the emulsion fuel specifications.

References

- Chiari, L., Zecca, A. (2011). Constraints of fossil fuels depletion on global warming projections. Energy Policy, 39 (9), 5026–5034. doi: https://doi.org/10.1016/j.enpol.2011.06.011

- Kumoro, A. C., Damayanti, A., Shiddieqy Bahlawan, Z. A., Melina, M., Puspawati, H. (2021). Bioethanol Production from Oil Palm Empty Fruit Bunches Using Saccharomyces cerevisiae Immobilized on Sodium Alginate Beads. Periodica Polytechnica Chemical Engineering, 65 (4), 493–504. doi: https://doi.org/10.3311/ppch.16775

- Shaibani, N., Yaghmaei, S., Andalibi, M. R., Ghazvini, S. (2012). Ethanol production from sugarcane bagasse by means of on-site produced and commercial enzymes; a comparative study. Periodica Polytechnica Chemical Engineering, 56 (2), 91. doi: https://doi.org/10.3311/pp.ch.2012-2.07

- Palankoev, T. A., Dementiev, K. I., Khadzhiev, S. N. (2019). Promising Processes for Producing Drop-in Biofuels and Petrochemicals from Renewable Feedstock (Review). Petroleum Chemistry, 59 (4), 438–446. doi: https://doi.org/10.1134/s096554411904011x

- Kálmán, G., Réczey, K. (2007). Possible ways of bio-refining and utilizing the residual lignocelluloses of corn growing and processing. Periodica Polytechnica Chemical Engineering, 51 (2), 29. doi: https://doi.org/10.3311/pp.ch.2007-2.05

- Qadir, S. A., Al-Motairi, H., Tahir, F., Al-Fagih, L. (2021). Incentives and strategies for financing the renewable energy transition: A review. Energy Reports, 7, 3590–3606. doi: https://doi.org/10.1016/j.egyr.2021.06.041

- Fehér, A., Bedő, S., Fehér, C. (2021). Comparison of Enzymatic and Acidic Fractionation of Corn Fiber for Glucose-rich Hydrolysate and Bioethanol Production by Candida boidinii. Periodica Polytechnica Chemical Engineering, 65 (3), 320–330. doi: https://doi.org/10.3311/ppch.17431

- Arun, J., Gopinath, K. P., Shreekanth, S. J., Sahana, R., Raghavi, M. S., Gnanaprakash, D. (2019). Effects of Process Parameters on Hydrothermal Liquefaction of Microalgae Biomass Grown in Municipal Wastewater. Petroleum Chemistry, 59 (2), 194–200. doi: https://doi.org/10.1134/s0965544119020026

- Netrusov, A. I., Teplyakov, V. V., Tsodikov, M. V., Chistyakov, A. V., Zharova, P. A., Shalygin, M. G. (2019). Production of Motor Fuel from Lignocellulose in a Three-Stage Process (Review and Experimental Article). Petroleum Chemistry, 59 (1), 11–23. doi: https://doi.org/10.1134/s0965544119010110

- Wang, X., Chen, Z., Ni, J., Liu, S., Zhou, H. (2015). The effects of hydrous ethanol gasoline on combustion and emission characteristics of a port injection gasoline engine. Case Studies in Thermal Engineering, 6, 147–154. doi: https://doi.org/10.1016/j.csite.2015.09.007

- Deng, X., Chen, Z., Wang, X., Zhen, H., Xie, R. (2018). Exhaust noise, performance and emission characteristics of spark ignition engine fuelled with pure gasoline and hydrous ethanol gasoline blends. Case Studies in Thermal Engineering, 12, 55–63. doi: https://doi.org/10.1016/j.csite.2018.02.004

- Kunwer, R., Ranjit Pasupuleti, S., Sureshchandra Bhurat, S., Kumar Gugulothu, S., Rathore, N. (2022). Blending of ethanol with gasoline and diesel fuel – A review. Materials Today: Proceedings, 69, 560–563. doi: https://doi.org/10.1016/j.matpr.2022.09.319

- Todoruț, A., Molea, A., Barabás, I. (2019). Predicting the Temperature and Composition – Dependent Density and Viscosity of Diesel Fuel – Ethanol Blends. Periodica Polytechnica Chemical Engineering, 64 (2), 213–220. doi: https://doi.org/10.3311/ppch.14757

- Qadiri, U. (2021). Computational parametric investigation on single cylinder constant speed spark ignition engine fuelled water-based micro-emulsion, ethanol blends, and conventional gasoline. Materials Science for Energy Technologies, 4, 256–262. doi: https://doi.org/10.1016/j.mset.2021.07.002

- Kyriakides, A., Dimas, V., Lymperopoulou, E., Karonis, D., Lois, E. (2013). Evaluation of gasoline–ethanol–water ternary mixtures used as a fuel for an Otto engine. Fuel, 108, 208–215. doi: https://doi.org/10.1016/j.fuel.2013.02.035

- Siciliano, B., da Silva, C. M., de Melo, T. C. C., Vicentini, P. C., Arbilla, G. (2022). An analysis of speciated hydrocarbons in hydrous ethanol (H100) and ethanol-gasoline blend (E22) for vehicle exhaust emissions. Atmospheric Environment, 285, 119248. doi: https://doi.org/10.1016/j.atmosenv.2022.119248

- EL-Seesy, A. I., Kayatas, Z., Takayama, R., He, Z., Kandasamy, S., Kosaka, H. (2020). Combustion and emission characteristics of RCEM and common rail diesel engine working with diesel fuel and ethanol/hydrous ethanol injected in the intake and exhaust port: Assessment and comparison. Energy Conversion and Management, 205, 112453. doi: https://doi.org/10.1016/j.enconman.2019.112453

- Saffy, H. A., Northrop, W. F., Kittelson, D. B., Boies, A. M. (2015). Energy, carbon dioxide and water use implications of hydrous ethanol production. Energy Conversion and Management, 105, 900–907. doi: https://doi.org/10.1016/j.enconman.2015.08.039

- Amine, M., Awad, E. N., Ibrahim, V., Barakat, Y. (2018). Influence of ethyl acetate addition on phase stability and fuel characteristics of hydrous ethanol-gasoline blends. Egyptian Journal of Petroleum, 27 (4), 1333–1336. doi: https://doi.org/10.1016/j.ejpe.2018.09.005

- Amine, M., Awad, E. N., Ibrahim, V., Barakat, Y. (2018). Effect of ethyl acetate addition on phase stability, octane number and volatility criteria of ethanol-gasoline blends. Egyptian Journal of Petroleum, 27 (4), 567–572. doi: https://doi.org/10.1016/j.ejpe.2017.08.007

- Al-Harbi, A. A., Alabduly, A. J., Alkhedhair, A. M., Alqahtani, N. B., Albishi, M. S. (2022). Effect of operation under lean conditions on NOx emissions and fuel consumption fueling an SI engine with hydrous ethanol–gasoline blends enhanced with synthesis gas. Energy, 238, 121694. doi: https://doi.org/10.1016/j.energy.2021.121694

- Murachman, B., Pranantyo, D., Sandjaya Putra, E. (2014). Study of Gasohol as Alternative Fuel for Gasoline Substitution: Characteristics and Performances. International Journal of Renewable Energy Development (IJRED), 3 (3). doi: https://doi.org/10.14710/ijred.3.3.175-183

- Amine, M., Barakat, Y. (2021). Effect of cyclohexanol on phase stability and volatility behavior of hydrous ethanol-gasoline blends. Egyptian Journal of Petroleum, 30 (3), 7–12. doi: https://doi.org/10.1016/j.ejpe.2021.04.001

- Saravanan, S., Pitchandi, K., Suresh, G. (2015). An experimental study on premixed charge compression ignition-direct ignition engine fueled with ethanol and gasohol. Alexandria Engineering Journal, 54 (4), 897–904. doi: https://doi.org/10.1016/j.aej.2015.07.010

- Kassem, M. G. A., Ahmed, A.-M. M., Abdel-Rahman, H. H., Moustafa, A. H. E. (2019). Use of Span 80 and Tween 80 for blending gasoline and alcohol in spark ignition engines. Energy Reports, 5, 221–230. doi: https://doi.org/10.1016/j.egyr.2019.01.009

- Ershov, М. А., Grigoreva, E. V., Habibullin, I. F., Emelyanov, V. E., Strekalina, D. M. (2016). Prospects of bioethanol fuels E30 and E85 application in Russia and technical requirements for their quality. Renewable and Sustainable Energy Reviews, 66, 228–232. doi: https://doi.org/10.1016/j.rser.2016.07.054

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Hanny Frans Sangian, Guntur Pasau, Gerald Hendrik Tamuntuan, Arief Widjaja, Ronny Purwadi, Silvya Yusnica Agnesty, Tun Sriana, Arif Nurrahman, Abubakar Tuhuloula, Ramli Thahir

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.