Surface quality improvement of steel parts by combined laser-ultrasonic treatment: determination algorithm of technological parameters

DOI:

https://doi.org/10.15587/1729-4061.2023.277252Keywords:

laser-ultrasonic treatment, AISI 1045 steel 45, AISI D2 steel, surface hardeningAbstract

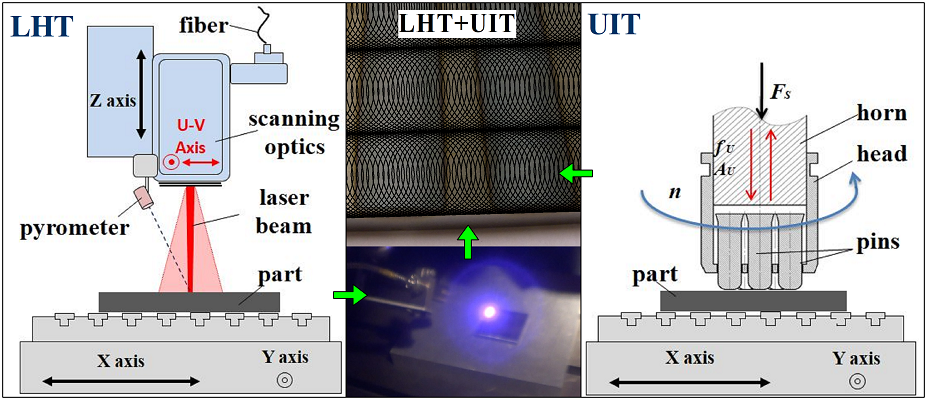

To provide the quality of the surface layer and improve operational properties, a combined laser-ultrasonic surface hardening and finishing technology of steel products is proposed. This work is devoted to determining the range of rational parameters of laser heat treatment and ultrasonic impact treatment for enhancing the complex hardening process of AISI 1045 steel and AISI D2 steel. Laser surface transformation hardening was carried out with a constant temperature strategy using a fiber laser and scanning optics at a heating temperature of 1200–1,300 °C and a processing speed of 40–140 mm/min. Ultrasonic surface hardening and finishing were performed on technological equipment with an amplitude of ultrasonic vibration of 18 μm and a load of the ultrasonic tool of 50 N. The ultrasonic treatment duration varied from 60 to 180 s. The results showed that laser-ultrasonic treatment leads to an increase in the hardening intensity by more than 200 %, forming a hardening depth of 200–440 μm. Combined treatment leads to a significant increase in wear resistance due to the formation of ultrafine-grained martensitic microstructure with hardness (58–60 HRC5) in the near-surface layer. The combined laser-ultrasonic hardening process control algorithm for surface treatment of structural and tool steels is proposed, limiting the heating temperature, the duration of laser (ultrasonic) exposure, and the vibration amplitudes of the ultrasonic horn. Laser-ultrasonic treatment will allow the formation of a surface layer with a given set of properties, providing increased wear and corrosion resistance. The developed technology can be used for surface hardening and finishing of large-sized steel products in the mechanical engineering industry.

References

- Roy, S., Zhao, J., Shrotriya, P., Sundararajan, S. (2017). Effect of laser treatment parameters on surface modification and tribological behavior of AISI 8620 steel. Tribology International, 112, 94–102. doi: https://doi.org/10.1016/j.triboint.2017.03.036

- Li, R., Jin, Y., Li, Z., Qi, K. (2014). A Comparative Study of High-Power Diode Laser and CO2 Laser Surface Hardening of AISI 1045 Steel. Journal of Materials Engineering and Performance, 23 (9), 3085–3091. doi: https://doi.org/10.1007/s11665-014-1146-x

- Kovalenko, V., Zhuk, R. (2004). Systemized approach in laser industrial systems design. Journal of Materials Processing Technology, 149 (1-3), 553–556. doi: https://doi.org/10.1016/j.jmatprotec.2004.02.020

- Ebrahimi, A., Sattari, M., Bremer, S. J. L., Luckabauer, M., Römer, G. R. B. E., Richardson, I. M. et al. (2022). The influence of laser characteristics on internal flow behaviour in laser melting of metallic substrates. Materials & Design, 214, 110385. doi: https://doi.org/10.1016/j.matdes.2022.110385

- Idan, A. F. І., Akimov, O., Golovko, L., Goncharuk, O., Kostyk, K. (2016). The study of the influence of laser hardening conditions on the change in properties of steels. Eastern-European Journal of Enterprise Technologies, 2 (5 (80)), 69–73. doi: https://doi.org/10.15587/1729-4061.2016.65455

- Berdnikova, O., Kushnarova, O., Bernatskyi, A., Alekseienko, T., Polovetskyi, Y., Khokhlov, M. (2020). Structure Peculiarities of the Surface Layers of Structural Steel under Laser Alloying. 2020 IEEE 10th International Conference Nanomaterials: Applications & Properties (NAP). doi: https://doi.org/10.1109/nap51477.2020.9309615

- Haskin, V. Y., Bernatskyi, A. V., Siora, O. V., Nikulin, O. T. (2011). Study of influence of conditions of process of laser superficial processing of the loaded steel articles on structure and properties of obtained layers. Metallofizika i Noveishie Tekhnologii, 33, 561–567.

- Zhu, L., Xue, P., Lan, Q., Meng, G., Ren, Y., Yang, Z. et al. (2021). Recent research and development status of laser cladding: A review. Optics & Laser Technology, 138, 106915. doi: https://doi.org/10.1016/j.optlastec.2021.106915

- Trojan, K., Ocelík, V., Čapek, J., Čech, J., Canelo-Yubero, D., Ganev, N. et al. (2022). Microstructure and Mechanical Properties of Laser Additive Manufactured H13 Tool Steel. Metals, 12 (2), 243. doi: https://doi.org/10.3390/met12020243

- Lesyk, D. A., Alnusirat, W., Martinez, S., Dzhemelinskyi, V. V., Mordyuk, B. N., Lamikiz, A. (2022). Enhancing hardness in overlapping scanner-based laser area of carbon and tool steel by multi-pin ultrasonic impact peening. Lasers in Manufacturing and Materials Processing, 9 (3), 292–311. doi: https://doi.org/10.1007/s40516-022-00178-2

- Lesyk, D., Hruska, M., Dzhemelinkyi, V., Danyleiko, O., Honner, M. (2022). Selective Surface Modification of Complexly Shaped Steel Parts by Robot-Assisted 3D Scanning Laser Hardening System. New Technologies, Development and Application V, 30–36. doi: https://doi.org/10.1007/978-3-031-05230-9_3

- Radziejewska, J., Skrzypek, S. J. (2009). Microstructure and residual stresses in surface layer of simultaneously laser alloyed and burnished steel. Journal of Materials Processing Technology, 209 (4), 2047–2056. doi: https://doi.org/10.1016/j.jmatprotec.2008.04.067

- Tian, Y., Shin, Y. C. (2007). Laser-assisted burnishing of metals. International Journal of Machine Tools and Manufacture, 47 (1), 14–22. doi: https://doi.org/10.1016/j.ijmachtools.2006.03.002

- Dzhemelinskyi, V., Lesyk, D., Goncharuk, O., Dаnyleikо, O. (2018). Surface hardening and finishing of metallic products by hybrid laserultrasonic treatment. Eastern-European Journal of Enterprise Technologies, 1 (12 (91)), 35–42. doi: https://doi.org/10.15587/1729-4061.2018.124031

- Lesyk, D., Martinez, S., Mordyuk, B., Dzhemelinskyi, V., Lamikiz, A. (2021). Wear Characteristics of Carbon and Tool Steels Hardened by Combined Laser-Ultrasonic Surface Treatment. Advances in Design, Simulation and Manufacturing IV, 62–72. doi: https://doi.org/10.1007/978-3-030-77719-7_7

- Kim, C., Park, S., Pyoun, Y., Shim, D. (2021). Effects of Ultrasonic Nanocrystal Surface Modification on Mechanical Properties of AISI D2 Steel. International Journal of Precision Engineering and Manufacturing, 22 (7), 1271–1284. doi: https://doi.org/10.1007/s12541-021-00536-8

- Mao, X., Sun, J., Feng, Y., Zhou, X., Zhao, X. (2019). High-temperature wear properties of gradient microstructure induced by ultrasonic impact treatment. Materials Letters, 246, 178–181. doi: https://doi.org/10.1016/j.matlet.2019.03.059

- Hu, X., Qu, S., Chen, Z., Zhang, P., Lu, Z., Lai, F. et al. (2022). Rolling contact fatigue behaviors of 25CrNi2MoV steel combined treated by discrete laser surface hardening and ultrasonic surface rolling. Optics & Laser Technology, 155, 108370. doi: https://doi.org/10.1016/j.optlastec.2022.108370

- Lesyk, D., Martinez, S., Mordyuk, B., Dzhemelinskyi, V., Danyleiko, O. (2019). Effects of the Combined Laser-Ultrasonic Surface Hardening Induced Microstructure and Phase State on Mechanical Properties of AISI D2 Tool Steel. Advances in Design, Simulation and Manufacturing II, 188–198. doi: https://doi.org/10.1007/978-3-030-22365-6_19

- Lesyk, D., Martinez, S., Mordyuk, B., Dzhemelinskyi, V., Danyleiko, O. (2018). Combined Laser-Ultrasonic Surface Hardening Process for Improving the Properties of Metallic Products. Advances in Design, Simulation and Manufacturing, 97–107. doi: https://doi.org/10.1007/978-3-319-93587-4_11

- Lesyk, D. A., Mordyuk, B. N., Martinez, S., Iefimov, M. O., Dzhemelinskyi, V. V., Lamikiz, А. (2020). Influence of combined laser heat treatment and ultrasonic impact treatment on microstructure and corrosion behavior of AISI 1045 steel. Surface and Coatings Technology, 401, 126275. doi: https://doi.org/10.1016/j.surfcoat.2020.126275

- Santhanakrishnan, S., Kong, F., Kovacevic, R. (2012). An experimentally based thermo-kinetic phase transformation model for multi-pass laser heat treatment by using high power direct diode laser. The International Journal of Advanced Manufacturing Technology, 64 (1-4), 219–238. doi: https://doi.org/10.1007/s00170-012-4029-z

- Lv, Y., Lei, L., Sun, L. (2015). Effect of shot peening on the fatigue resistance of laser surface melted 20CrMnTi steel gear. Materials Science and Engineering: A, 629, 8–15. doi: https://doi.org/10.1016/j.msea.2015.01.074

- Wang, Z., Jiang, C., Gan, X., Chen, Y., Ji, V. (2011). Influence of shot peening on the fatigue life of laser hardened 17-4PH steel. International Journal of Fatigue, 33 (4), 549–556. doi: https://doi.org/10.1016/j.ijfatigue.2010.10.010

- Danyleiko, O., Dzhemelinskyi, V., Lesyk, D. (2021). Increasing wear and corrosion resistance of steel products by combined laser thermomechanical treatment. Eastern-European Journal of Enterprise Technologies, 6 (1 (114)), 72–80. doi: https://doi.org/10.15587/1729-4061.2021.247552

- Souza, P. S., Cangussu, V. M., Câmara, M. A., Abrão, A. M., Denkena, B., Breidenstein, B., Meyer, K. (2020). Formation of White Etching Layers by Deep Rolling of AISI 4140 Steel. Journal of Materials Engineering and Performance, 29 (7), 4351–4359. doi: https://doi.org/10.1007/s11665-020-04988-3

- Liu, C., Lin, C., Liu, W., Wang, S., Chen, Y., Wang, J., Wang, J. (2021). Effects of local ultrasonic impact treatment on residual stress in an engineering-scale stainless steel pipe girth weld. International Journal of Pressure Vessels and Piping, 192, 104420. doi: https://doi.org/10.1016/j.ijpvp.2021.104420

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Dmytro Lesyk, Vitaliy Dzhemelinskyi, Bohdan Mordyuk, Silvia Martinez, Pavlo Kondrashev, Dariusz Grzesiak, Yurii Klyuchnikov, Аitzol Lamikiz

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.