Assessing the stresses and magnitude of plastic hinge in a tunnel conduit made of precast metal corrugated structures taking into account the soil backfill parameters

DOI:

https://doi.org/10.15587/1729-4061.2023.285893Keywords:

precast metal corrugated structures, tunnel conduit, stress of metal structures, plastic hingeAbstract

The object of research is a tunnel conduit made of star-shaped metal corrugated structures.

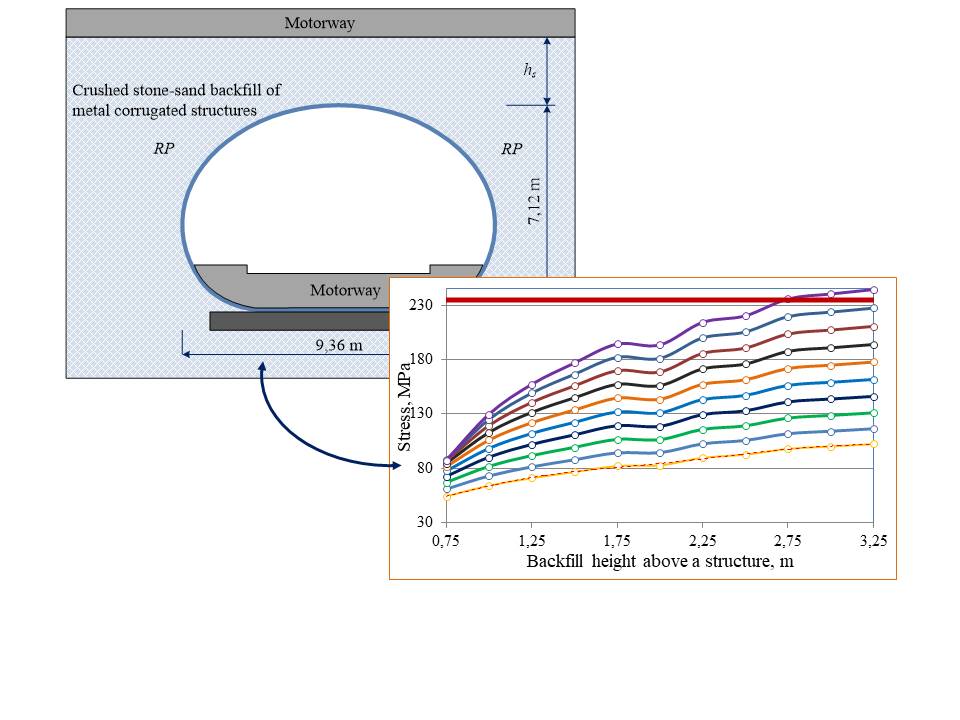

The stresses and magnitude of the plastic hinge occurring in the metal corrugated structures of the tunnel conduit were investigated, taking into account the degree of compaction and the height of the soil backfill.

It was established that when the height of the backfill above the tunnel conduit made of precast metal corrugated structures increases and the degree of compaction of the soil backfill decreases, there is an increase in the values of stresses and plastic hinge in metal structures. With the height of the backfill above the conduit equal to 2.75 m and the degree of compaction of the soil backfill RP=80 %, stresses of 235.89 MPa are reached, exceeding the permissible 235 MPa. At the same time, the value of the plastic hinge is 1.03, which exceeds the normative 1.0.

It was established that at embankment heights above the tunnel conduit structures from 1.75 m to 2.0 m, the smallest difference in stresses and magnitude of the plastic hinge is observed. At RP=98 %, the stress difference is 0.66 MPa, and the value of the plastic hinge is 0.008. In the case of the height of the embankment above the conduit from 1.5 m to 1.75 m, the stress increase was 5.5 MPa, and the value of the plastic hinge – 0.031. When the embankment height increases from 2.0 m to 2.25 m, the stress difference is 7.57 MPa, and the value of the plastic hinge is 0.041.

It was determined that when the height of the embankment above the conduit was increased by 1.0 m in the range from 0.75 m to 1.75 m, the stress difference at RP=98 % increased by 27.84 MPa. However, when the height was increased by 1.0 m in the range from 2.75 m to 3.75 m, the stress difference increased by 12.66 MPa. At the same time, the value of the plastic hinge at embankment heights from 0.75 m to 1.75 m increased by 0.139, and at embankment heights from 2.75 m to 3.75 m – by 0.093

References

- Kovalchuk, V., Koval, M., Onyshchenko, A., Kravets, I., Bal, O., Markul, R. et al. (2022). Determining the strained state of prefabricated metal corrugated structures of a tunnel overpass exposed to the dynamic loading from railroad rolling stock. Eastern-European Journal of Enterprise Technologies, 3 (7 (117)), 50–58. doi: https://doi.org/10.15587/1729-4061.2022.259439

- Stasiuk, B. M., Stankevych, V. Z., Kovalchuk, V. V., Luchko, Y. Y. (2014). Doslidzhennia napruzheno-deformovanoho stanu metalevykh hofrovanykh konstruktsiy pry vzaiemodiyi z gruntom zasypky. Zbirnyk nauk. prats Dnipropet-rovskoho nats. un-tu zalizn. transportu im. akadem. V. Lazariana «Mosty ta tuneli: Teoriia, doslidzhennia, praktyka», 5, 105–111.

- Kunecki, B., Korusiewicz, L. (2013). Field tests of large-span metal arch culvert during backfilling. Roads and Bridges – Drogi i Mosty, 12, 283–295. doi: https://doi.org/10.7409/rabdim.013.020

- Korusiewicz, L., Kunecki, B. (2011). Behaviour of the steel box-type culvert during backfilling. Archives of Civil and Mechanical Engineering, 11 (3), 637–650. doi: https://doi.org/10.1016/s1644-9665(12)60106-x

- Mak, A. C., Brachman, R. W. I., Moore, I. D. (2009). Measured Response of a Deeply Corrugated Box Culvert to Vehicle Loads. Transportation Research Board 88th Annual Meeting. Washington. Available at: https://trid.trb.org/view/882050

- Maleska, T., Beben, D. (2018). Behaviour of corrugated steel plate bridge with high soil cover under seismic excitation. MATEC Web of Conferences, 174, 04003. doi: https://doi.org/10.1051/matecconf/201817404003

- Mistewicz, M. (2019). Risk assessment of the use of corrugated metal sheets for construction of road soil-shell structures. Roads and Bridges - Drogi i Mosty, 18 (2), 89–107. doi: http://dx.doi.org/10.7409/rabdim.019.006

- Beben, D. (2017). Experimental Testing of Soil-Steel Railway Bridge Under Normal Train Loads. Experimental Vibration Analysis for Civil Structures, 805–815. doi: https://doi.org/10.1007/978-3-319-67443-8_71

- Kovalchuk, V., Luchko, J., Bondarenko, I., Markul, R., Parneta, B. (2016). Research and analysis of the stressed-strained state of metal corrugated structures of railroad tracks. Eastern-European Journal of Enterprise Technologies, 6 (7 (84)), 4–9. doi: https://doi.org/10.15587/1729-4061.2016.84236

- Kovalchuk, V., Markul, R., Pentsak, A., Parneta, B., Gayda, O., Braichenko, S. (2017). Study of the stress-strain state in defective railway reinforced-concrete pipes restored with corrugated metal structures. Eastern-European Journal of Enterprise Technologies, 5 (1 (89)), 37–44. doi: https://doi.org/10.15587/1729-4061.2017.109611

- Kovalchuk, V., Kovalchuk, Y., Sysyn, M., Stankevych, V., Petrenko, O. (2018). Estimation of carrying capacity of metallic corrugated structures of the type Multiplate MP 150 during interaction with backfill soil. Eastern-European Journal of Enterprise Technologies, 1 (1 (91)), 18–26. doi: https://doi.org/10.15587/1729-4061.2018.123002

- Gera, B., Kovalchuk, V. (2019). A study of the effects of climatic temperature changes on the corrugated structure. Eastern-European Journal of Enterprise Technologies, 3 (7 (99)), 26–35. doi: https://doi.org/10.15587/1729-4061.2019.168260

- Machelski, C., Korusiewicz, L. (2017). Deformation of buried corrugated metal box structure under railway load. Roads and Bridges - Drogi i Mosty, 16, 191–201. doi: https://doi.org/10.7409/rabdim.017.013

- Beben, D. (2009). Numerical analysis of a soil-steel bridge structure. The Baltic Journal of Road and Bridge Engineering, 4 (1), 13–21. doi: https://doi.org/10.3846/1822-427x.2009.4.13-21

- Embaby, K., Hesham El Naggar, M., El Sharnouby, M. (2022). Investigation of bevel-ended large-span soil-steel structures. Engineering Structures, 267, 114658. doi: https://doi.org/10.1016/j.engstruct.2022.114658

- Embaby, K., El Naggar, M. H., El Sharnouby, M. (2022). Performance of large-span arched soil–steel structures under soil loading. Thin-Walled Structures, 172, 108884. doi: https://doi.org/10.1016/j.tws.2022.108884

- Koval, M., Koval, P., Kovalchuk, V. (2020). Methods of tunnel inspection and testing of metal corrugated structures at km 228 + 160 of Kyiv-Kharkiv-Dovzhansky highway. Dorogi i Mosti, 2020 (21), 250–269. doi: https://doi.org/10.36100/dorogimosti2020.21.250

- Pettersson, L., Hansing, L. (2002). Fatigue design of soil steel composite bridges. Archives of institute of civil engineering, 12, 237–242.

- Pettersson, L., Sundquist, H. (2007). Design of soil steel composite bridges. Structural Desing and Bridges. Stockholm, 98.

- Kloppel, K., Glock, D. (1970). Theoretische und experimentelle Untersuchungen zu den Traglastproblemen biegeweicher, in die Erde eingebetteter Rohre. Institut für Statik und Stahlbau der Technischen Hochschule Darmstadt.

- Wysokowski, A., Janusz, L. (2007). Mostowe konstrukcje gruntowo–powlokowe. Laboratoryjne badania niszczace. Awarie w czasie budowy i eksploatacji. XXIII konferencja naukowo-techniczna. Szcecin, 541–550. Available at: http://www.awarie.zut.edu.pl/files/ab2007/artykuly/0136.pdf

- Pettersson, L., Flener, E. B., Sundquist, H. (2015). Design of Soil–Steel Composite Bridges. Structural Engineering International, 25 (2), 159–172. doi: https://doi.org/10.2749/101686614x14043795570499

- Maleska, T., Beben, D. (2023). Behaviour of Soil–Steel Composite Bridges under Strong Seismic Excitation with Various Boundary Conditions. Materials, 16 (2), 650. doi: https://doi.org/10.3390/ma16020650

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Vitalii Kovalchuk, Ihor Karnakov, Artur Onyshchenko, Oleksiy Petrenko, Roman Boikiv

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.