Development of rational technology for sodium glyceroxide obtaining

DOI:

https://doi.org/10.15587/1729-4061.2022.265087Keywords:

sodium glyceroxide, sodium hydroxide, alkali metal glyceroxides, fat transesterification catalystAbstract

The process of sodium glyceroxide obtaining by the reaction of glycerol and sodium hydroxide in the form of an aqueous solution was investigated.

Glycerol salts (metal glyceroxides) are important components in the synthesis of many compounds. Glyceroxides are used in the chemical industry, construction, medical practice, etc. Glyceroxides of alkali metals are used in the production of modified fats and biodiesel fuel.

P.a.-grade glycerol (CAS Number 56-81-5) was used with a mass fraction of the main substance of 99.5 %. The parameters of sodium hydroxide (CAS Number 1310-73-2) were studied: the mass fraction of the main substance is 98.0 %, the mass fraction of sodium carbonate is 0.5%.

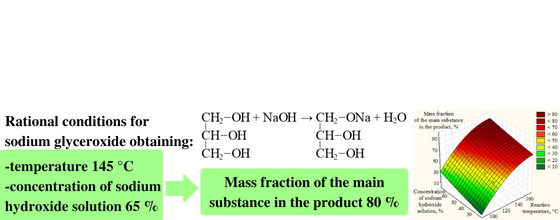

Rational conditions for sodium glyceroxide obtaining were determined: temperature (145 °C) and concentration of sodium hydroxide solution (65 %). Under these conditions, the mass fraction of the main substance in the product was 80 %. The melting point (72 °C) and mass fraction of moisture (0.3 %) in sodium glyceroxide were determined. The catalytic activity of the product in the process of transesterification of palm olein was tested. The increase in the melting point of palm olein was 15 °C. Under similar conditions of using potassium glyceroxide with a mass fraction of the main substance of 75.77 %, the increase in the melting point is 12.1 °C. This indicates an increase in the efficiency of the transesterification process using sodium glyceroxide obtained by the developed technology.

The research results make it possible to produce sodium glyceroxide under rational conditions with a high mass fraction of the main substance at enterprises that use metal glyceroxides as a production component or commercial product. The determined rational conditions will make it possible to effectively use the company's resources and predict the quality of the final product

References

- Pradhan, S., Shen, J., Emami, S., Mohanty, P., Naik, S. N., Dalai, A. K., Reaney, M. J. T. (2017). Synthesis of potassium glyceroxide catalyst for sustainable green fuel (biodiesel) production. Journal of Industrial and Engineering Chemistry, 46, 266–272. doi: https://doi.org/10.1016/j.jiec.2016.10.038

- Rahmankulov, D. L., Kimsanov, B. H., Chanyshev, R. R. (2003). Fizicheskie i himicheskie svoystva glicerina. Moscow: Himiya, 200.

- Sytnik, N., Kunitsia, E., Mazaeva, V., Chernukha, A., Ostapov, K., Borodych, P. et. al. (2021). Establishing rational conditions for obtaining potassium glycerate. Eastern-European Journal of Enterprise Technologies, 3 (6 (111)), 12–18. doi: https://doi.org/10.15587/1729-4061.2021.231449

- Ebadi Pour, N., Dumeignil, F., Katryniok, B., Delevoye, L., Revel, B., Paul, S. (2021). Investigating the active phase of Ca-based glycerol polymerization catalysts: On the importance of calcium glycerolate. Molecular Catalysis, 507, 111571. doi: https://doi.org/10.1016/j.mcat.2021.111571

- Bliznjuk, O., Masalitina, N., Mezentseva, I., Novozhylova, T., Korchak, M., Haliasnyi, I. et. al. (2022). Development of safe technology of obtaining fatty acid monoglycerides using a new catalyst. Eastern-European Journal of Enterprise Technologies, 2 (6 (116)), 13–18. doi: https://doi.org/10.15587/1729-4061.2022.253655

- Malpartida, I., Maireles-Torres, P., Vereda, C., Rodríguez-Maroto, J. M., Halloumi, S., Lair, V. et. al. (2020). Semi-continuous mechanochemical process for biodiesel production under heterogeneous catalysis using calcium diglyceroxide. Renewable Energy, 159, 117–126. doi: https://doi.org/10.1016/j.renene.2020.05.020

- Korchak, M., Yermakov, S., Maisus, V., Oleksiyko, S., Pukas, V., Zavadskaya, I. (2020). Problems of field contamination when growing energy corn as monoculture. E3S Web of Conferences, 154, 01009. doi: https://doi.org/10.1051/e3sconf/202015401009

- Korchak, M., Yermakov, S., Hutsol, T., Burko, L., Tulej, W. (2021). Features of weediness of the field by root residues of corn. ENVIRONMENT. TECHNOLOGIES. RESOURCES. Proceedings of the International Scientific and Practical Conference, 1, 122–126. doi: https://doi.org/10.17770/etr2021vol1.6541

- Kwok, Q., Acheson, B., Turcotte, R., Janès, A., Marlair, G. (2013). Fire and explosion hazards related to the industrial use of potassium and sodium methoxides. Journal of Hazardous Materials, 250-251, 484–490. doi: https://doi.org/10.1016/j.jhazmat.2013.01.075

- Reyero, I., Arzamendi, G., Gandía, L. M. (2014). Heterogenization of the biodiesel synthesis catalysis: CaO and novel calcium compounds as transesterification catalysts. Chemical Engineering Research and Design, 92 (8), 1519–1530. doi: https://doi.org/10.1016/j.cherd.2013.11.017

- Bradley, D., Levin, E., Rodriguez, C., Williard, P. G., Stanton, A., Socha, A. M. (2016). Equilibrium studies of canola oil transesterification using a sodium glyceroxide catalyst prepared from a biodiesel waste stream. Fuel Processing Technology, 146, 70–75. doi: https://doi.org/10.1016/j.fuproc.2016.02.009

- Wang, E., Shen, J., Wang, Y., Tang, S., Emami, S., Reaney, M. J. T. (2015). Production of biodiesel with lithium glyceroxide. Fuel, 160, 621–628. doi: https://doi.org/10.1016/j.fuel.2015.07.101

- Ferrero, G. O., Almeida, M. F., Alvim-Ferraz, M. C. M., Dias, J. M. (2014). Water-free process for eco-friendly purification of biodiesel obtained using a heterogeneous Ca-based catalyst. Fuel Processing Technology, 121, 114–118. doi: https://doi.org/10.1016/j.fuproc.2014.01.020

- Esipovich, A., Danov, S., Belousov, A., Rogozhin, A. (2014). Improving methods of CaO transesterification activity. Journal of Molecular Catalysis A: Chemical, 395, 225–233. doi: https://doi.org/10.1016/j.molcata.2014.08.011

- Ferrero, G. O., Almeida, M. F., Alvim-Ferraz, M. C. M., Dias, J. M. (2015). Glycerol-enriched heterogeneous catalyst for biodiesel production from soybean oil and waste frying oil. Energy Conversion and Management, 89, 665–671. doi: https://doi.org/10.1016/j.enconman.2014.10.032

- León-Reina, L., Cabeza, A., Rius, J., Maireles-Torres, P., Alba-Rubio, A. C., López Granados, M. (2013). Structural and surface study of calcium glyceroxide, an active phase for biodiesel production under heterogeneous catalysis. Journal of Catalysis, 300, 30–36. doi: https://doi.org/10.1016/j.jcat.2012.12.016

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Mykola Korchak, Olga Bliznjuk, Serhii Nekrasov, Tatiana Gavrish, Olena Petrova, Natalia Shevchuk, Liudmyla Strikha, Oleg Kostyrkin, Evgeny Semenov, Dmytro Saveliev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.