Оцінка величини гідравлічного коефіцієнта тертя в трубопроводах, що працюють з приєднаням витрати вздовж шляху

DOI:

https://doi.org/10.15587/1729-4061.2022.265670Ключові слова:

збірний перфорований трубопровід, змінна витрата, гідравлічний коефіцієнт тертяАнотація

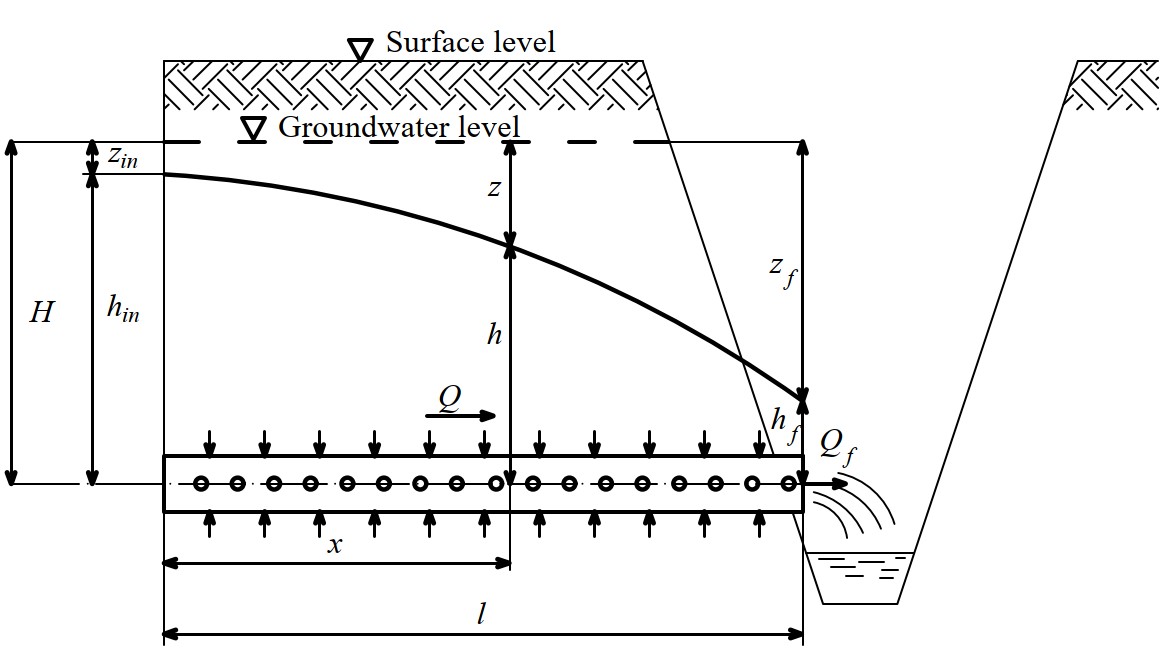

Представлені результати експериментальних досліджень гідравлічного коефіцієнта тертя перфорованих трубопроводів, які працюють зі збором рідини вздовж шляху. З’ясування даного питання дозволить вирішити важливу інженерну задачу – розробити надійну методику гідравлічного розрахунку перфорованих труб. Експерименти проводились на змонтованому дослідному стенді. Досліджувався сталевий трубопровід з перфорованою частиною 1–3 м. Отвори перфорації приймалися діаметром 3, 6 і 9 мм. В дослідах вимірювалась витрата рідини, втрати напору, епюри осереднених швидкостей. За отриманими даними розраховувалися значення досліджуваного коефіцієнта. Встановлено, що він суттєво більше від його значень при рівномірному русі і є змінним за довжиною трубопроводу. Отримано експериментальні залежності λзб від величини співвідношення швидкостей втікаючих струминок рідини до середньої швидкості руху потоку у відповідному перерізі (Uo/V), а також від конструктивних характеристик каналу. Показано, що меншому значенню степені перфорації труби відповідають більші значення λзб. Даний результат можна пояснити впливом приєднуваної витрати на основний потік, Підтвердженням цього висновку слугують отримані в дослідах форми епюр осереднених швидкостей руху потоку, які суттєво відрізняються від стандартних епюр при рівномірному русі. Очевидно, що на переформування епюр швидкостей витрачається додаткова енергія, а це викликає виникнення додаткових втрат напору. В роботі отримано залежності для розрахунку розглядуваного коефіцієнта для збірних трубопроводів, в тому числі і при наявності транзитної витрати. Їх застосування при розрахунку розглядуваних труб дозволить підвищити надійність і ефективність роботи очисних споруд, в яких вони є важливими конструктивними елементами

Посилання

- Bihun, I. (2019). Peculiarities of application pressure distributive pipelines in different engineering systems. Theory and Building Practice, 1 (2), 14–20. doi: https://doi.org/10.23939/jtbp2019.02.014

- Valipour, M., Krasilnikof, J., Yannopoulos, S., Kumar, R., Deng, J., Roccaro, P. et. al. (2020). The Evolution of Agricultural Drainage from the Earliest Times to the Present. Sustainability, 12 (1), 416. doi: https://doi.org/10.3390/su12010416

- Cao, Y., Xu, M., Ni, P., Mei, G. (2021). Physical and numerical modelling of infiltration from drainage holes for perforated storm sewer. Acta Geotechnica, 17 (2), 527–543. doi: https://doi.org/10.1007/s11440-021-01247-0

- Martynov, S., Kvartenko, O., Kovalchuk, V., Orlova, A. (2020). Modern trends at natural and wastewater treatment plants reconstruction. IOP Conference Series: Materials Science and Engineering, 907 (1), 012083. doi: https://doi.org/10.1088/1757-899x/907/1/012083

- Zhang, Q., Wang, Z. (2014). Modeling Study on Fluid Flow in Horizontal Perforated Pipes with Wall Influx. International Journal of Fluid Mechanics Research, 41 (6), 556–566. doi: https://doi.org/10.1615/interjfluidmechres.v41.i6.80

- Qin, Z., Liu, H., Wang, Y. (2017). Empirical and quantitative study of the velocity distribution index of the perforated pipe outflowing along a pipeline. Flow Measurement and Instrumentation, 58, 46–51. doi: https://doi.org/10.1016/j.flowmeasinst.2017.09.010

- Liu, H., Zong, Q., Lv, H., Jin, J. (2017). Analytical equation for outflow along the flow in a perforated fluid distribution pipe. PLOS ONE, 12 (10), e0185842. doi: https://doi.org/10.1371/journal.pone.0185842

- Kravchuk, O., Kravchuk, O. (2020). Evaluation of the impact of different head loss types on the collecting pipelines working character-istics. Problems of Water Supply, Sewerage and Hydraulic, 34, 19–24. doi: https://doi.org/10.32347/2524-0021.2020.34.19-24

- Al'tshul', A. D. (1970). Gidravlicheskie soprotivleniya. Moscow: Nedra, 216.

- Meerovich, I. G., Muchnik, G. F. (1986). Gidrodinamika kollektornykh sistem. Moscow: Nauka, 144.

- Shima, N., Saito, N., Okamoto, M. (1999). Prediction of Wall-Bounded Turbulent Flows with Blowing and Suction. Testing of a Second-Moment Closure without Wall-Reflection Redistribution Terms. JSME International Journal Series B, 42 (4), 626–633. doi: https://doi.org/10.1299/jsmeb.42.626

- Cherniuk, V., Hnativ, R., Kravchuk, O., Orel, V., Bihun, I., Cherniuk, M. (2021). The problem of hydraulic calculation of pressure distribution pipelines. Eastern-European Journal of Enterprise Technologies, 6 (7 (114)), 93–103. doi: https://doi.org/10.15587/1729-4061.2021.246852

- Clemo, T. (2006). Flow in Perforated Pipes: A Comparison of Models and Experiments. SPE Production & Operations, 21 (02), 302–311. doi: https://doi.org/10.2118/89036-pa

- Cherniuk, V., Ivaniv, V. (2017). Influence of Values of Angle of Jet-joining on Non-uniformity of Water Inflow Along the Path in Pressure Collector-Pipeline. Proccedings of 10th International Conference “Environmental Engineering”. doi: https://doi.org/10.3846/enviro.2017.073

- Krogstad, P.-A., Kourakine, A. (1999). The Response of a Turbulent Boundary Layer to Injection through a Porous Strip. Proceeding of First Symposium on Turbulence and Shear Flow Phenomena. doi: https://doi.org/10.1615/tsfp1.700

- Naumenko, I. I., Voloshchuk, V. A. (2001). Matematychni modeli dlia hidravlichnykh rozrakhunkiv truboprovodiv z dyskretno zrostaiuchymy vytratamy. Visnyk Rivnenskoho derzhavnoho tekhnichnoho universytetu, 1 (8), 88–99.

- Murphy, P., Kaye, N. B., Khan, A. A. (2014). Hydraulic Performance of Aggregate Beds with Perforated Pipe Underdrains Flowing Full. Journal of Irrigation and Drainage Engineering, 140 (8). doi: https://doi.org/10.1061/(asce)ir.1943-4774.0000740

- Eliahou, S., Tumin, A., Wygnanski, I. (1998). Laminar–turbulent transition in Poiseuille pipe flow subjected to periodic perturbation emanating from the wall. Journal of Fluid Mechanics, 361, 333–349. doi: https://doi.org/10.1017/s002211209800888x

- Kravchuk, A., Kochetov, G., Kravchuk, O. (2020). Improving the calculation of collecting perforated pipelines for water treatment structures. Eastern-European Journal of Enterprise Technologies, 6 (10 (108)), 23–28. doi: https://doi.org/10.15587/1729-4061.2020.216366

- Egorov, A. I. (1984). Gidravlika napornykh trubchatykh sistem v vodoprovodnykh ochistnykh sooruzheniyakh. Moscow: Stroyizdat, 95.

- Kravchuk, A., Kochetov, G., Kravchuk, O. (2020). Pipelines designing for steady water collection along the path. Problems of Water Supply, Sewerage and Hydraulic, 33, 34–40. doi: https://doi.org/10.32347/2524-0021.2020.33.34-40

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2022 Andriy Kravchuk, Volodymyr Cherniuk, Oleksandr Kravchuk, Tamara Airapetian

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.