Justification of safe shelf life of whole wheat flour of various sizes, depending on the processing method

DOI:

https://doi.org/10.15587/1729-4061.2022.265812Keywords:

whole grain flour, gas treatment, grinding size, safe storage, quality indicatorsAbstract

The objects of this study were wheat grain (Shortandinskaya variety, harvest 2021) and wheat grain grinding products – whole grain (whole-ground) wheat flour of coarse, medium, and fine grinds.

Studies have been carried out to establish the terms of safe storage of whole-grain (whole-ground) wheat flour of various sizes. Samples of whole-grain flour of coarse, medium, and fine grinding were obtained by grinding wheat grain in a finger-type single-rotor eight-row disintegrator.

The resistance to storage of samples of whole-grain wheat flour of various sizes, as well as treated with gases (nitrogen, carbon dioxide) with a concentration of 2.0 mg/l, at a pressure of P=2.0 atm for 10 minutes, was investigated.

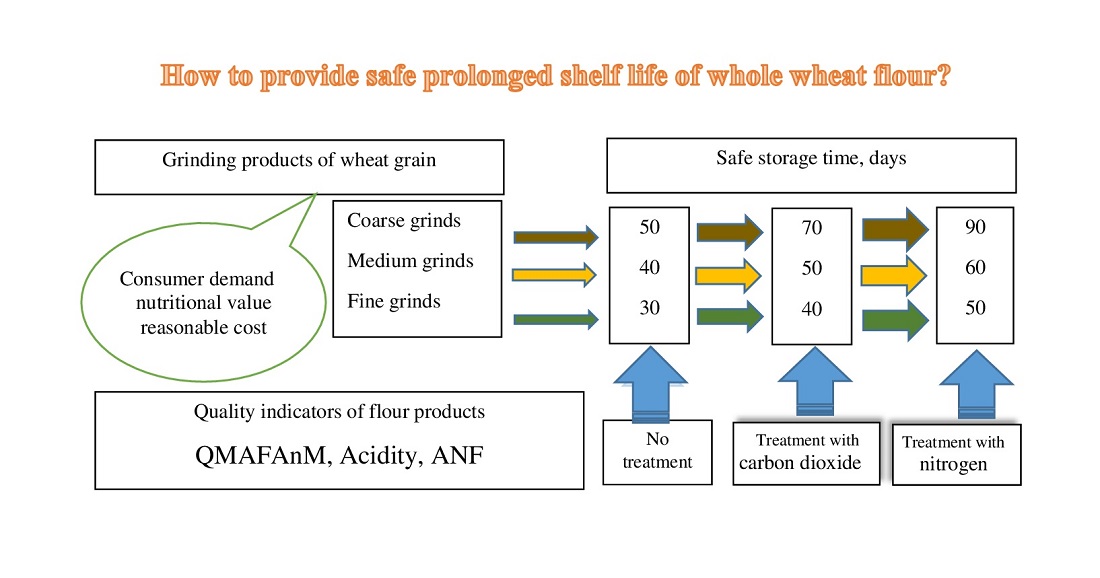

Based on the indicators of QMAFAnM, the acid number of fat, and the acidity of gas-processed and unprocessed whole-grain wheat flour of various sizes, the terms of its safe storage were established. All safety indicators were examined within three months with a frequency of every 10 days. The relationship between the size of the flour product and its stability during storage has been established. It is recommended to store unprocessed whole grain wheat flour of coarse grinding up to 50 days, medium grinding – up to 40 days, fine grinding – up to 30 days.

The treatment of whole-grain flour before storage with carbon dioxide has made it possible to prolong the period of safe storage of coarse flour to 70 days, medium grinding – up to 50 days, fine grinding – up to 40 days.

The best results in the preservation of whole-grain flour, depending on the size of the grind, were shown by its treatment before storage with nitrogen in comparison with similar treatment with carbon dioxide. Nitrogen treatment has made it possible to recommend the duration of safe storage of coarse flour up to 90 days, medium – up to 60 days, small – up to 50 days

References

- Bahrami, N., Bayliss, D., Chope, G., Penson, S., Perehinec, T., Fisk, I. D. (2016). Cold plasma: A new technology to modify wheat flour functionality. Food Chemistry, 202, 247–253. doi: https://doi.org/10.1016/j.foodchem.2016.01.113

- Sandhu, H. P., Manthey, F. A., Simsek, S. (2011). Quality of bread made from ozonated wheat (Triticum aestivum L.) flour. Journal of the Science of Food and Agriculture, 91 (9), 1576–1584. doi: https://doi.org/10.1002/jsfa.4350

- Cheng, Z., Li, X., Hu, J., Fan, X., Hu, X., Wu, G., Xing, Y. (2021). Effect of Gaseous Chlorine Dioxide Treatment on the Quality Characteristics of Buckwheat-Based Composite Flour and Storage Stability of Fresh Noodles. Processes, 9 (9), 1522. doi: https://doi.org/10.3390/pr9091522

- Lee, H., Ryu, J.-H., Kim, H. (2020). Antimicrobial activity of gaseous chlorine dioxide against Aspergillus flavus on green coffee beans. Food Microbiology, 86, 103308. doi: https://doi.org/10.1016/j.fm.2019.103308

- Sun, X., Baldwin, E., Bai, J. (2019). Applications of gaseous chlorine dioxide on postharvest handling and storage of fruits and vegetables – A review. Food Control, 95, 18–26. doi: https://doi.org/10.1016/j.foodcont.2018.07.044

- Sun, C., Zhu, P., Ji, J., Sun, J., Tang, L., Pi, F., Sun, X. (2017). Role of aqueous chlorine dioxide in controlling the growth of Fusarium graminearum and its application on contaminated wheat. LWT, 84, 555–561. doi: https://doi.org/10.1016/j.lwt.2017.03.032

- Moroney, M., Watrelot, A., Savits, J. (2022). Use of Inert Gases. Iowa State University. Available at: https://store.extension.iastate.edu/product/16405

- Adler, C., Corinth, H. G., Reichmuth, C.; Subramanyam, B., Hagstrum, D. W. (Eds.) (2000). Modified Atmosphere. Alternatives to Pesticides in Stored Product IPM. Kluwes Academic Publishers, 105–146. doi: http://doi.org/10.1007/978-1-4615-4353-4_5

- Navarro, S.; Heaps, D. W. (Ed.) (2006). Modified atmospheres for the control of stored product insects and mites. Insect Management for Food Storage and Processing, AACC international. St. Paul. Minnesota, 105–145. doi: http://doi.org/10.1016/b978-1-891127-46-5.50016-7

- Győriné Mile, I., Győri, Z. (2006). Testing the quality of winter wheat under traditional storage conditions and storing in inert gas. Cereal Research Communications, 34 (1), 465–468. doi: https://doi.org/10.1556/crc.34.2006.1.116

- Ebian, P. E. F., Aamir, P. M. M., Mahgoub, P. S. M., Shalaby, P. A. M. (2017). Effect of pressurized CO2, N2 and air gases on different stages of Oryzaephilus surinamensis (L.) and Stegobium paniceum (L.). Zagazig Journal of Agricultural Research, 44 (6A), 2255–2266. doi: http://doi.org/10.21608/zjar.2017.51294

- Riudavets, J., Castañé, C., Alomar, O., Pons, M. J., Gabarra, R. (2009). Modified atmosphere packaging (MAP) as an alternative measure for controlling ten pests that attack processed food products. Journal of Stored Products Research, 45 (2), 91–96. doi: https://doi.org/10.1016/j.jspr.2008.10.001

- Locatelli, D. P., Suss, L., Frati, M. (1999). The use of high pressure carbon dioxide (20 bar) to control some insects of foodstuffs. Proc. of the 7th Int. Work. Conf. Stored-Product Prot. Sichuan Publishing House of Sci. and Tech. Beijing, 1, 671–675.

- Selivanov, A. (2019). Roskachestvo razrabotalo klassifikatciiu zernovogo khleba. Available at: https://ivbg.ru/8029881-roskachestvo-razrabotalo-klassifikaciyu-zernovogo-xleba.html

- Lazutkin, A. A., Moiseeva, A. I. (2010). Sposoby povysheniia funktcionalnykh svoistv khlebobulochnykh izdelii na osnove tcelnosmolotogo zerna pshenitcy. Khranenie i pererabotka selkhozsyria, 2, 26–29.

- Berezovikova, I. P. (2011). Obosnovanie rezhimov mikronizatcii zerna pshenitcy dlia proizvodstva tcelnozernovykh produktov. Tekhnika i tekhnolgiia pishchevykh proizvodstv, 3 (22), 5–8.

- Naumenko, N. V., Potoroko, I. Yu., Velyamov, M. T. (2019). Sprouted whole wheat grain as a food constituent in food technology. Bulletin of the South Ural State University Series Food and Biotechnology, 7 (3), 23–30. doi: https://doi.org/10.14529/food190303

- Maemerov, M. M., Iztaev, A. I., Kulazhanov, T. K., Iskakova, G. K. (2011). Nauchnye osnovy ionnoozonnoi tekhnologii obrabotki zerna i produktov ego pererabotki. Almaty: Izd. Aleiron, 246.

- Shaimerdenova, D. A., Chakanova, Zh. M., Iskakova, D. M., Sarbassova, G. T., Bekbolatova, M. B., Yesmambetov, A. A. (2022). Storage of extruded cereal and legume grain bases in ion-ozone medium. SABRAO Journal of Breeding and Genetics, 54 (1), 165–174. doi: https://doi.org/10.54910/sabrao2022.54.1.15

- Shaimerdenova, D. A., Chakanova, Zh. M., Iskakova, D. M., Sarbassova, G. T., Bekbolatova, M. B., Yesmambetov, A. A. (2020). Effective method of grain processing using in grain bases for foods: Methods of grain bases production. EurAsian Journal of BioSciences, 14, 6291–6302.

- Anisimova, L. V., Akhmed, S. O. I. (2017). Stoikost pri khranenii ovsianoi muki, poluchennoi raznymi sposobami. Polzunovskii vestnik, 4, 14–20.

- Kheins, L. S., Levain, G. I., Sleid, L., Chzhou, N., Mannz, D., Gannon, D. (2013). Pat. No. RU2472345C2. Poluchenie stabilizirovannoi tcelnozernovoi muki i produktov iz nee. Available at: https://patents.google.com/patent/RU2472345C2/ru

- Izmenenie kachestva muki pri khranenii. Available at: studref.com/381903/tovarovedenie/izmenenie_kachestva_muki_hranenii

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Farrukh Makhmudov, Sanavar Azimova, Maigul Kizatova, Auyelbek Iztayev, Olga Shanina

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.