Development of information support for simulation of the process of deformation of root polymer plate in book blocks sewed with threads

DOI:

https://doi.org/10.15587/1729-4061.2022.265869Keywords:

simulation model, root adhesive plate, implanted thread stitches, discrete loadsAbstract

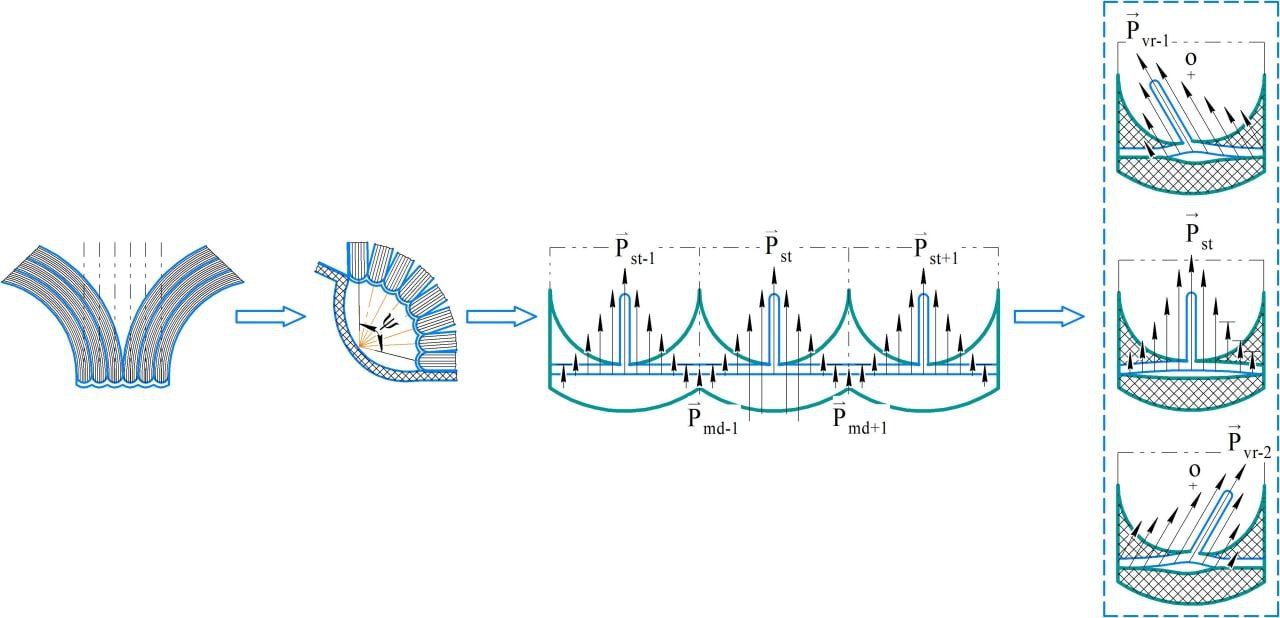

The object of this study is the processes of deformation of the root polymer plate reinforced with stitches of threads with preliminary tension in book blocks sewn with threads. The analytical and experimental studies reported here are based on the application of the methodology for developing a simulation model of the process of deforming the adhesive polymer plate. The basic assumption of the study is that the use of information support for simulation modeling will contribute to the improvement of the structural and technological parameters of the root part of the book blocks sewn with threads. This cannot be achieved without analyzing and decomposition of the technical system of the book block, classifying subsystems and describing them in the form of a finite set of classes and the connections between them. A procedure for determining the mechanism of interaction of elements of the root part of book blocks sewn with threads is proposed. It is shown that the residual cyclic deformation of the adhesive plate and the stitches of the implanted threads depends on the strength of the bonds between the elements of the joined structure of the materials. It also depends on the number of cycles of discrete loads heterogeneous in terms of dimensional indicators and the place of their application. This is due to the fact that stitches of threads are only partially implanted into the structure of the adhesive plate, the other part that fastens the folds of notebooks is outside the adhesive plate. The influence of cyclic loads applied at different angles relative to the stitches of the threads was revealed. The angular discrepancy fluctuates, in the case of using PVAD D51C glue, in the range of 0.735–0.907, and, for Technomelt GE3636 thermal glue, 0.913–0.940. The developed simulation model of the processes of deformation of the root polymer plate makes it possible to determine the mechanism of interaction of the elements of the root part of the book blocks and predict the durability of the product

References

- Kyrychok, P., Paliukh, O., Oliynyk, V. (2020). Determining the influence of the thickness of an adhesive layer on a change in the angles of contact and tangent angles. Eastern-European Journal of Enterprise Technologies, 3 (1 (105)), 52–67. doi: https://doi.org/10.15587/1729-4061.2020.203439

- Shtefan, E., Pashchenko, B., Blagenko, S., Yastreba, S. (2018). Constitutive Equation for Numerical Simulation of Elastic-Viscous – Plastic Disperse Materials Deformation Process. Advances in Design, Simulation and Manufacturing Proceedings of the International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, DSMIE-2018. Springer International Publishing AG. Part of Springer Nature, 1, 356–363. doi: https://doi.org/10.1007/978-3-319-93587-4_37

- Petković, G., Pasanec Preprotić, S., Vukoje, M. (2018). The quality assessment of bookbinding strength for polyvinyl acetate adhesive (PVAc) and nano-modified PVAc adhesives. Proceedings of 9th International Symposium on Graphic Engineering and Design. doi: https://doi.org/10.24867/grid-2018-p13

- Mukhurova, E. A., Gaiduk, S. S., Shetko, S. V. (2014). Uvelichenie prochnosti kleevogo soedineniia aktiviruiushchei obrabotkoi poverkhnostei skleivaniia. Trudy BGTU, 2 (166), 125–127.

- Jaafar, J., Siregar, J. P., Mohd Salleh, S., Mohd Hamdan, M. H., Cionita, T., Rihayat, T. (2019). Important Considerations in Manufacturing of Natural Fiber Composites: A Review. International Journal of Precision Engineering and Manufacturing-Green Technology, 6 (3), 647–664. doi: https://doi.org/10.1007/s40684-019-00097-2

- Kaushik, V. K., Kumar, A., Kalia, S. (2013). Effect of Mercerization and Benzoyl Peroxide Treatment on Morphology, Thermal Stability and Crystallinity of Sisal Fibers. International Journal of Textile Science, 1 (6), 101–105. doi: https://doi.org/10.5923/j.textile.20120106.07

- Slotska, L. S., Zatserkovna, R. S. (2018). The research of adhesive films’ physical-mechanical features during gluing of spines of book blocks, sewn with threads. Printing and Publishing, 2 (76), 20–26. doi: https://doi.org/10.32403/0554-4866-2018-2-76-20-26

- Karthikeyan, S., Rajini, N., Jawaid, M., Winowlin Jappes, J., Thariq, M., Siengchin, S., Sukumaran, J. (2017). A review on tribological properties of natural fiber based sustainable hybrid composite. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 231 (12), 1616–1634. doi: https://doi.org/10.1177/1350650117705261

- Suriani, M. J., Rapi, H. Z., Ilyas, R. A., Petrů, M., Sapuan, S. M. (2021). Delamination and Manufacturing Defects in Natural Fiber-Reinforced Hybrid Composite: A Review. Polymers, 13 (8), 1323. doi: https://doi.org/10.3390/polym13081323

- Mohammed, L., Ansari, M. N. M., Pua, G., Jawaid, M., Islam, M. S. (2015). A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. International Journal of Polymer Science, 2015, 1–15. doi: https://doi.org/10.1155/2015/243947

- Khalid, M. Y., Imran, R., Arif, Z. U., Akram, N., Arshad, H., Al Rashid, A., García Márquez, F. P. (2021). Developments in Chemical Treatments, Manufacturing Techniques and Potential Applications of Natural-Fibers-Based Biodegradable Composites. Coatings, 11 (3), 293. doi: https://doi.org/10.3390/coatings11030293

- Abral, H., Ariksa, J., Mahardika, M., Handayani, D., Aminah, I., Sandrawati, N. et. al. (2020). Transparent and antimicrobial cellulose film from ginger nanofiber. Food Hydrocolloids, 98, 105266. doi: https://doi.org/10.1016/j.foodhyd.2019.105266

- Petryashvyly, H. H. (2007). Matematycheskaia model napriazhenno-deformyrovannoho sostoianyia kleevoho soedynenyia knyzhnoho bloka. Polihrafiia i vydavnycha sprava, 1 (45), 181–185.

- Havenko, S. F., Lohaziak, I. Yu., Turiab, L. V. (2012). Doslidzhennia faktoriv vplyvu na kuty rozkryvannia knyzhkovykh blokiv. Tekhnolohiia i tekhnika drukarstva, 1, 67–73. Available at: http://nbuv.gov.ua/UJRN/Titd_2012_1_12

- Kyrychok, P., Paliukh, O. (2020). Simulation of Deformation of the Adhesive Layer of the Spine of the Book Back of the Thread-Stitched Book Block. Mechanics, 26 (2), 114–119. doi: https://doi.org/10.5755/j01.mech.26.2.25854

- Hetman, I. A., Vasylieva, L. V. (2017). Tekhnolohii proektuvannia informatsiinykh system. Computer Sciences and System Sciences (CS&SS-2017), 76–79. Available at: http://dspace.puet.edu.ua/bitstream/123456789/5499/1/09%20%D0%93%D0%B5%D1%82%D1%8C%D0%BC%D0%B0%D0%BD%20%D0%92%D0%B0%D1%81%D0%B8%D0%BB%D1%8C%D1%94%D0%B2%D0%B0.pdf

- Senkivskyi, V. M., Pikh, I. V., Senkivska, N. Ye. (2016). Theoretical bases of quality assurance of publishing and printing processes (Part 1: introduction general principles). Naukovi zapysky Ukrainska akademiia drukarstva, 1 (52), 22–31.Available at: http://nbuv.gov.ua/UJRN/Nz_2016_1_4

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Oleksandr Paliukh, Petro Kyrychok, Yevheniy Shtefan, Andrii Titov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.