Establishment of regularities of isothermal flow and mixture formation in microjet burners with three-row jet fuel supply

DOI:

https://doi.org/10.15587/1729-4061.2022.267891Keywords:

microjet burners, flow structure, mixture formation of fuel and oxidizer, jet fuel supplyAbstract

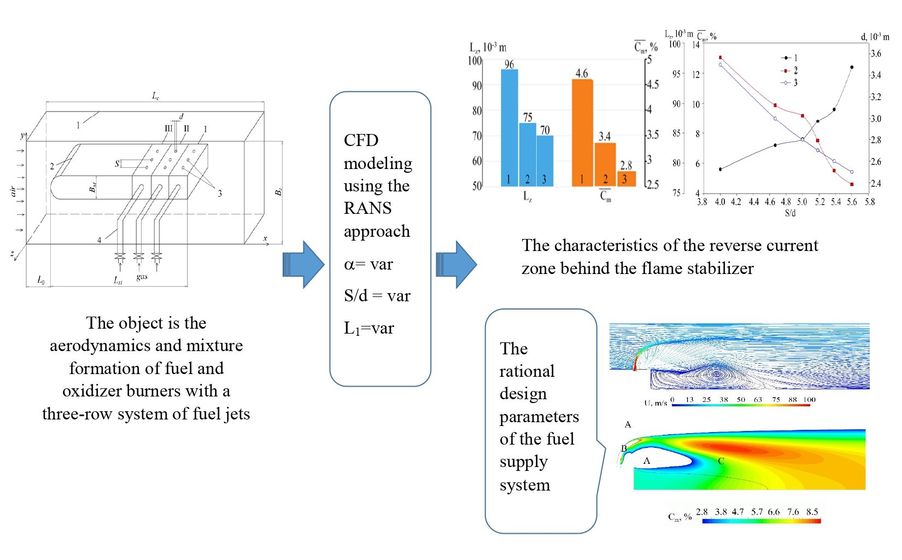

The object of this research is the aerodynamics and mixture formation of fuel and oxidizer in stabilizer-type burners with a three-row system of fuel jets, focused on operation at coefficients of excess air 1.1...1.5. The study was conducted on the basis of CFD modeling using the RANS (Reynolds Averaged Navier-Stokes) approach.

The analysis of the basic regularities of the course of these processes in the proposed microjet burners was carried out. In this case, special attention was paid to the consideration of the characteristics of flow and mixture formation in the aft region of the flame stabilizer, where vortex structures are formed that are responsible for stabilizing the torch.

The regularities of influence on the flow and mixture formation in the proposed burner devices of such factors as the row number NR of the jet fuel supply, the relative pitch, S/d, of the location of gas supply holes and the coefficient of excess air, α, have been investigated. The presence of noticeable differences in the structure of flow and mixture formation in burners during fuel supply to different rows of gas supply holes has been established. It is shown that aerodynamics and the pattern of mixing fuel and oxidizer undergo significant changes when varying the value of S/d.

For the considered burner devices, rational design parameters of the fuel supply system have been determined, at which favorable conditions for mixture formation in the field of flame stabilization are ensured. In particular, it is shown that the rational S/d values are 5.4; 5.6; and 5.8, respectively, for the first, second, and third sections of the fuel supply.

The results can be widely used in energy practice for objects operated under conditions of variable values of the coefficient of excess air

References

- Warnatz, J., Maas, U., Dibble, R. W. (2003). Combustion. Physical and Chemical Fundamentals, Modeling and Simulation, Experiments, Pollutant Formation. Springer, 299. doi: https://doi.org/10.1007/978-3-662-04508-4

- Tran, A., Aguirre, A., Durand, H., Crose, M., Christofides, P. D. (2017). CFD modeling of a industrial-scale steam methane reforming furnace. Chemical Engineering Science, 171, 576–598. doi: https://doi.org/10.1016/j.ces.2017.06.001

- Gianetti, G., Sforza, L., Lucchini, T., D’Errico, G., Soltic, P., Rojewski, J., Hardy, G. (2019). CFD modeling of natural gas engine combustion with a flame area evolution model. AIP Conference Proceedings. doi: https://doi.org/10.1063/1.5138820

- van Oijen, J. A., Donini, A., Bastiaans, R. J. M., ten Thije Boonkkamp, J. H. M., de Goey, L. P. H. (2016). State-of-the-art in premixed combustion modeling using flamelet generated manifolds. Progress in Energy and Combustion Science, 57, 30–74. doi: https://doi.org/10.1016/j.pecs.2016.07.001

- Perpignan, A. A. V., Talboom, M. G., Levy, Y., Rao, A. G. (2018). Emission Modeling of an Interturbine Burner Based on Flameless Combustion. Energy & Fuels, 32 (1), 822–838. doi: https://doi.org/10.1021/acs.energyfuels.7b02473

- Hosseini, S. E., Wahid, M. A. (2014). Investigation of bluff-body micro-flameless combustion. Energy Conversion and Management, 88, 120–128. doi: https://doi.org/10.1016/j.enconman.2014.08.023

- Askarova, A. S., Messerle, V. E., Bolegenova, S. A., Maksimov, V. Yu., Bolegenova, S. A., Nugymanova, A. O. (2022). Influence of the method of air-fuel mixture supply on the main characteristics of heat and mass transfer processes. Thermophysics and Aeromechanics, 29 (1), 107–124. doi: https://doi.org/10.1134/s0869864322010097

- Stefanizzi, M., Stefanizzi, S., Ceglie, V., Capurso, T., Torresi, M., Camporeale, S. M. (2021). Analysis of the partially premixed combustion in a labscale swirl-stabilized burner fueled by a methane-hydrogen mixture. E3S Web of Conferences, 312, 11004. doi: https://doi.org/10.1051/e3sconf/202131211004

- Fialko, N., Prokopov, V., Sherenkovskii, J., Aleshko, S., Meranova, N. (2021). Influence of the primary and secondary air consumption ratio on the microjet burner devices efficiency. Chap. 10.2. Technical research and development. Boston, 430–434. Available at: https://isg-konf.com/wp-content/uploads/2021/04/Monograph-USA-Technical-2021-I-isg-konf.pdf

- Fialko, N., Prokopov, V., Sherenkovskiy, J., Tymoshchenko, O., Polozenko, N., Kutnyak, O. et al. (2020). Analysis of the possibilities of regulating the process of mixture formation in microjet burners with cylindrical flame stabilizers. International Scientific Journal “Internauka,” 12. doi: https://doi.org/10.25313/2520-2057-2020-12-6215

- Jones, W. P., Marquis, A. J., Wang, F. (2015). Large eddy simulation of a premixed propane turbulent bluff body flame using the Eulerian stochastic field method. Fuel, 140, 514–525. doi: https://doi.org/10.1016/j.fuel.2014.06.050

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Nataliia Fialko, Nataliia Meranova, Julii Sherenkovskii, Sergey Aleshko, Michael Abdulin, Vitalii Babak, Volodymyr Korzhyk, Vasyl Zhelykh, Roman Dinzhos, Vladyslav Khaskin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.