Determining patterns in the formation of cordierite phase during the synthesis of density-sintered low-temperature ceramics based on glasses of the MgO–Al2O3–SiO2 system

DOI:

https://doi.org/10.15587/1729-4061.2022.268140Keywords:

cordierite ceramics, eutectic glass, MgO–Al2O3–SiO2 system, thermodynamic analysis, X-ray phase analysisAbstract

The search for effective modifiers of the structure of densely baked cordierite ceramics to reduce the firing temperature is a relevant task but typically requires a large amount of experimental research. The object of this study is the reaction of the formation of the cordierite phase with the participation of glass components of the eutectic compositions of the MgO– Al2O3–SiO2 system under low-temperature firing conditions. In this case, thermodynamic analysis was used as a tool to assess the probability of chemical reactions. Thermodynamic analysis can significantly reduce the volume of the experimental sample.

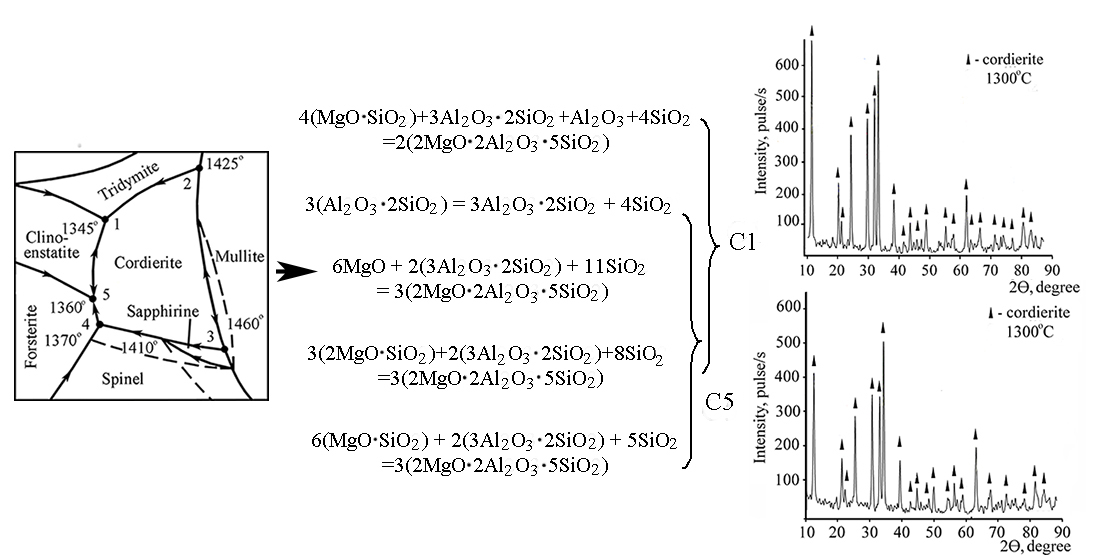

This paper reports the results of theoretical and experimental studies into the features of the course of chemical reactions with the participation of glass components of eutectic compositions of the MgO–Al2O3–SiO2 system. It was revealed that once the stoichiometric ratio is maintained, the resulting product of the interaction between the components of eutectic glasses of the MgO–Al2O3–SiO2 system with charging components is cordierite. Changes in the mineralogical composition of cordierite compositions depending on the firing temperature have been determined. The formation of the cordierite phase is preceded by the process of transformation of meta kaolinite Al2O3·2SiO2, which is a product of kaolin dehydration, into mullite 3Al2O3·2SiO2. Subsequently, the formation of cordierite (in addition to crystallizing directly from eutectic glasses) occurs with the participation of the mullite phase. The formation of the cordierite phase occurs in several stages and is completed at a temperature of 1300 °C. The established features of the reactions of cordierite formation make it possible to determine the most optimal compositions for glasses of the MgO–Al2O3–SiO2 system to obtain low-temperature cordierite ceramics with a high degree of sintering. At the same time, it is also possible to control the phase composition of ceramics and its properties

References

- Zanotto, E. D. (2010). A Bright future for glass-ceramics. American Ceramic Society Bulletin, 89 (8), 19–27. Available at: https://ceramics.org/wp-content/uploads/2010/09/bulletin_oct-nov2010.pdf

- Sebastian, M. T., Ubic, R., Jantunen, H. (2015). Low-loss dielectric ceramic materials and their properties. International Materials Reviews, 60 (7), 392–412. doi: https://doi.org/10.1179/1743280415y.0000000007

- Pivinskii, Yu. E. (2017). The half of a century period of the domestic ceramics technology development. Part I. Novye ogneupory (New Refractories), 3, 105–112. doi: https://doi.org/10.17073/1683-4518-2017-3-105-112

- Zaychuk, A.V., Amelina, A.A. (2017). Search for the ways to improve the physical and technical parameters of quartz ceramics. Voprosy Khimii i Khimicheskoi Tekhnologii, 6, 63–67. Available at: http://nbuv.gov.ua/UJRN/Vchem_2017_6_12

- Khomenko, E. S. (2018). Quartz ceramics modified by nanodispersed silica additive. Functional Materials, 25 (3), 613–618. doi: https://doi.org/10.15407/fm25.03.613

- Lutpi, H. A., Mohamad, H., Abdullah, T. K., Ismail, H. (2021). Effect of sintering treatment time on the sintering behaviour and thermal shock resistance of Li2O-Al2O3-SiO2 glass-ceramics. Journal of Asian Ceramic Societies, 9 (2), 507–518. doi: https://doi.org/10.1080/21870764.2021.1896094

- Zaichuk, A. V., Amelina, A. A., Khomenko, Y. S., Baskevich, A. S., Kalishenko, Y. R. (2020). Heat-resistant ceramics of b-eucryptite composition: peculiarities of production, microstructure and properties. Voprosy Khimii i Khimicheskoi Tekhnologii, 2, 52–59. doi: https://doi.org/10.32434/0321-4095-2020-129-2-52-59

- Zaichuk, A. V., Kalishenko, Y. R., Amelina, A. A., Hordieiev, Y. S., Halushka, S. A., Savchenko, O. S., Nahornyi, M. V. (2022). Features of formation of the celsian phase during firing of heat-resistant ceramics in the system BaO–Al2O3–SiO2. Voprosy Khimii i Khimicheskoi Tekhnologii, 3, 26–32. doi: https://doi.org/10.32434/0321-4095-2022-142-3-26-32

- Sung, Y. M., Kim, S. (2000). Sintering and crystallization of off-stoichiometric SrO•Al2O3•2SiO2 glasses. Journal of Materials Science, 35 (17), 4293–4299. doi: https://doi.org/10.1023/A:1004880201847

- Sung, Y.-M., Kwak, W.-C. (2002). Influence of various heating procedures on the sintered density of Sr-celsian glass-ceramic. Journal of materials science letters, 21 (11), 841–843. doi: https://doi.org/10.1023/a:1015710309425

- Ptáček, P., Šoukal, F., Opravil, T., Bartoníčková, E., Wasserbauer, J. (2016). The formation of feldspar strontian (SrAl2Si2O8) via ceramic route: Reaction mechanism, kinetics and thermodynamics of the process. Ceramics International, 42 (7), 8170–8178. doi: https://doi.org/10.1016/j.ceramint.2016.02.024

- López-Badillo, C. M., López-Cuevas, J., Gutiérrez-Chavarría, C. A., Rodríguez-Galicia, J. L., Pech-Canul, M. I. (2013). Synthesis and characterization of BaAl2Si2O8 using mechanically activated precursor mixtures containing coal fly ash. Journal of the European Ceramic Society, 33 (15-16), 3287–3300. doi: https://doi.org/10.1016/j.jeurceramsoc.2013.05.014

- Zaichuk, A. V., Amelina, A. A., Hordieiev, Yu. S., Kalishenko, Y. R., Sribniak, N. N. (2020). Synthesis and characteristic of celsian ceramics with the use of glass in the system Li2O-Al2O3-B2O3-SiO2. Functional Materials, 27, 827–835. doi: https://doi.org/10.15407/fm27.04.827

- Zaichuk, A. V. (2019). Radio-transparent ceramic materials of spodumene-cordierite composition. Functional Materials, 26 (1), 174–181. doi: https://doi.org/10.15407/fm26.01.174

- Zaichuk, O., Amelina, A., Hordieiev, Y., Kalishenko, Y., Sribniak, N., Halushka, S. et al. (2020). Patternsin the synthesis processes, the microstructure and properties of strontium-anorthite ceramics modified by glass of spodumene composition. Eastern-European Journal of Enterprise Technologies, 6 (6 (108)), 15–26. doi: https://doi.org/10.15587/1729-4061.2020.216754

- Shamsudin, Z., Hodzic, A., Soutis, C., Hand, R. J., Hayes, S. A., Bond, I. P. (2011). Characterisation of thermo-mechanical properties of MgO–Al2O3–SiO2 glass ceramic with different heat treatment temperatures. Journal of Materials Science, 46 (17), 5822–5829. doi: https://doi.org/10.1007/s10853-011-5538-0

- Poteshkina, A. A., Uvarenkova, J. A., Ivanova, V. I., Ivanov, D. M. (2015). Ceramic dielectrics with low dielectric constant for microwave application. Vestnik SPbGU, 4 (2 (60)), 285–293.

- Aşkın, A., Tatar, İ., Kılınç, Ş., Tezel, Ö. (2017). The Utilization of Waste Magnesite in the Production of the Cordierite Ceramic. Energy Procedia, 107, 137–143. doi: https://doi.org/10.1016/j.egypro.2016.12.151

- Chainikova, A. S., Vaganova, M. L., Shchegoleva, N. E., Lebedeva, Yu. E. (2015). Technological aspects of fabrication of radiotransparent glass-ceramic materials based on high-temperature aluminosilicate systems (review). Proceedings of VIAM, 11, 4–4. doi: https://doi.org/10.18577/2307-6046-2015-0-11-4-4

- Stoch, L., Lelatko, J. (2008). Mechanisms of crystal structure organization in magnesium aluminosilicate glass: HREM and analytical study. European Journal of Glass Science and Technology, 48, 183–188.

- Guignard, M., Cormier, L., Montouillout, V., Menguy, N., Massiot, D., Hannon, A. C. (2009). Environment of titanium and aluminum in a magnesium alumino-silicate glass. Journal of Physics: Condensed Matter, 21 (37), 375107. doi: https://doi.org/10.1088/0953-8984/21/37/375107

- Reda, A. E., Abd-El-Raoof, F., Ahmed, S. E., Abdel Aziz, D. A., Mahani, R. (2020). Sintering and dielectric behavior for doped cordierite by xCuO within MgO (1-x)–Al2O3–SiO2 ceramics. Materials Chemistry and Physics, 243, 122616. doi: https://doi.org/10.1016/j.matchemphys.2019.122616

- Torres, F. J., Rodríguez-Mendoza, U. R., Lavín, V., de Sola, E. R., Alarcón, J. (2007). Evolution of the structural and optical properties from cobalt cordierite glass to glass-ceramic based on spinel crystalline phase materials. Journal of Non-Crystalline Solids, 353 (44-46), 4093–4101. doi: https://doi.org/10.1016/j.jnoncrysol.2007.06.014

- Zalapa-Garibay, M. A., Torres-Torres, D., Arizmendi-Morquecho, A. M., Reyes-López, S. Y. (2019). Effect of NiO and MoO3 addition on the crystallinity and mechanical properties of α-cordierite and β-cordierite in the MgO-Al2O3-SiO2 system. Results in Physics, 13, 102227. doi: https://doi.org/10.1016/j.rinp.2019.102227

- Banjuraizah, J., Mohamad, H., Ahmad, Z. A. (2011). Effect of impurities content from minerals on phase transformation, densification and crystallization of α-cordierite glass-ceramic. Journal of Alloys and Compounds, 509 (28), 7645–7651. doi: https://doi.org/10.1016/j.jallcom.2011.04.129

- Obradović, N., Đorđević, N., Filipović, S., Nikolić, N., Kosanović, D., Mitrić, M. et al. (2012). Influence of mechanochemical activation on the sintering of cordierite ceramics in the presence of Bi2O3 as a functional additive. Powder Technology, 218, 157–161. doi: https://doi.org/10.1016/j.powtec.2011.12.012

- Ivanov, D. M., Luk'yanova, N. A., Ivanova, V. I., Petukhova, V. V. (2009). Sintez kordierita dlya vysokochastotnogo primeneniya. Vestn. S.-Peterb. un-ta. Fizika, khimiya, 4, 77–82.

- Zaichuk, A., Amelina, A., Kalishenko, Y., Hordieiev, Y., Saltykov, D., Sribniak, N. et al. (2021). Aspects of development and properties of densely sintered of ultra-high-frequency radio-transparent ceramics of cordierite composition. Journal of the Korean Ceramic Society, 58 (4), 483–494. doi: https://doi.org/10.1007/s43207-021-00125-5

- Belyankin, D. S., Lapin, V. V., Toropov, N. A. (1954). Fiziko-khimicheskie sistemy silikatnoy tekhnologi. Moscow: Promstroyizdat, 506.

- Gui, H., Li, C., Lin, C., Zhang, Q., Luo, Z., Han, L. et al. (2019). Glass forming, crystallization, and physical properties of MgO-Al2O3-SiO2-B2O3 glass-ceramics modified by ZnO replacing MgO. Journal of the European Ceramic Society, 39 (4), 1397–1410. doi: https://doi.org/10.1016/j.jeurceramsoc.2018.10.002

- Minakova, N. A., Zaichuk, A. V., Belyi, Ya. I. (2008). The structure of borate glass. Glass and Ceramics, 65 (3-4), 70–73. doi: https://doi.org/10.1007/s10717-008-9017-2

- Bobkova, N. M., Silich, L. M., Tereschenko, I. M. (1990). Sbornik zadach po fizicheskoy khimii silikatov i tugoplavkikh soedineniy. Minsk: Universitetskoe, 175.

- Binnewies, M., Milke, E. (2002). Thermochemical Data of Elements and Compounds, 2rd Edition, Wiley-VCH Verlag GmbH. doi: https://doi.org/10.1002/9783527618347

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Oleksandr Zaichuk, Aleksandra Amelina, Yuliia Kalishenko, Yurii Hordieiev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.