Establishing changes in the parameters of teat rubber for milking machines during testing and under industrial conditions

DOI:

https://doi.org/10.15587/1729-4061.2023.272030Keywords:

teat rubber, rubber characteristic, rubber parameters, composite materials, rubber wear, closing vacuumAbstract

The teat rubber of milking machines is the only structural component of all milking and dairy equipment that is in contact with animals. During operation, the rubber article’s original quality characteristics are compromised. This is due to mechanical wear during operation.

The task of the research is to establish changes in the parameters of the teat rubber of milking machines during testing and under industrial conditions. The object of research was the teat rubber of milking machines from various manufacturers, made of various composite materials.

A scientific hypothesis put forward assumed that an increase in the efficiency of milking and dairy equipment could be achieved by establishing changes in the parameters of the teat rubber with subsequent maintenance planning. This would provide an opportunity to identify patterns and dependences that characterize these processes.

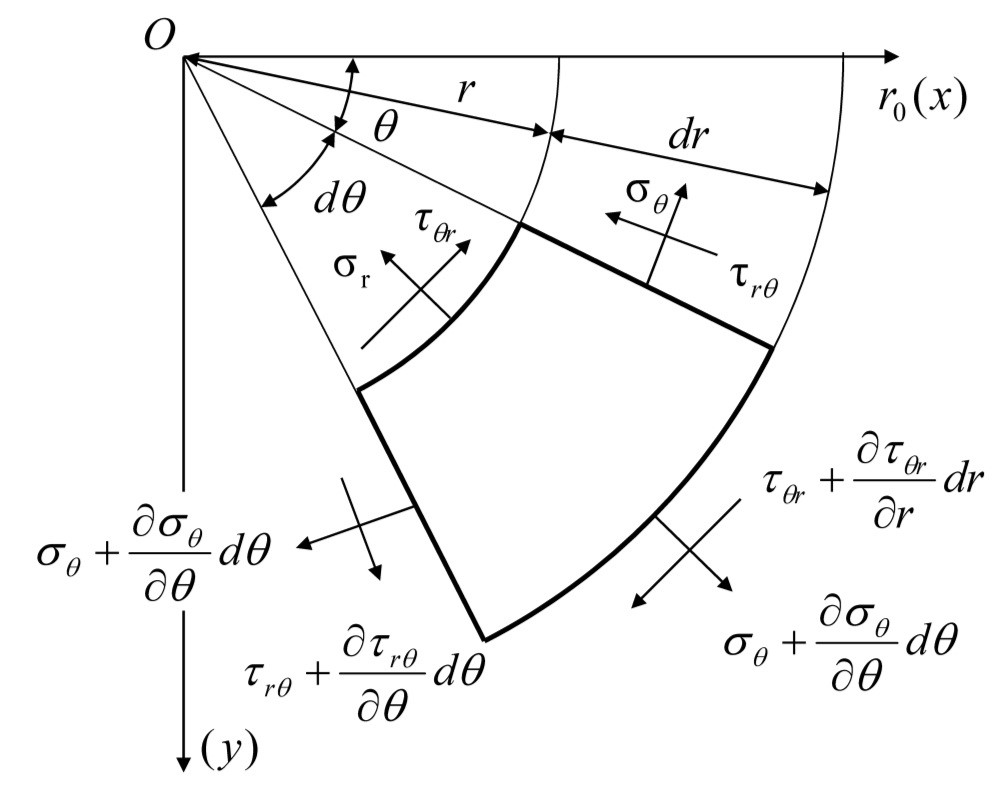

In the course of research, theoretical dependences were derived to determine the operation of teat rubber in idle mode and the theoretical time of its operation. It was established that the theoretical wear period of the teat rubber is about 120–170 hours.

It was determined that in the environment of SZHR-3, the coefficient of aging in terms of intensity was >2 times higher compared to Skydrol LD-4. The volume under similar conditions of exposure of liquids on samples exceeded by more than 3 times. It is proved that the change in the mass of rubber under the influence of SZHR-3 exceeds more than 2.5 times the indicators obtained from the effects of Skydrol LD-4.

It was established that during long-term operation the teat rubber undergoes changes in its physical and mechanical properties. Thus, hardness and elasticity increase, elasticity decreases due to the destruction of the internal structure of rubber due to the formation of microcracks, the vacuum of closing the walls increases.

Knowledge of the quality characteristics of the teat rubber would make it possible to find the optimal solution for the choice of rubber articles

References

- Lüdi, I., Bruckmaier, R. M. (2022). The teat cup detachment level affects milking performance in an automatic milking system with teat cleaning and milking in the same teat cup. Journal of Dairy Research, 89 (3), 279–284. doi: https://doi.org/10.1017/s0022029922000528

- Aliiev, E., Paliy, A., Kis, V., Paliy, A., Petrov, R., Plyuta, L. et al. (2022). Establishing the influence of technical and technological parameters of milking equipment on the efficiency of machine milking. Eastern-European Journal of Enterprise Technologies, 1 (1 (115)), 44–55. doi: https://doi.org/10.15587/1729-4061.2022.251172

- Neuheuser, A.-L., Belo, C., Bruckmaier, R. M. (2017). Technical note: Reduced pulsation chamber vacuum at normal pulsation rate and ratio provides adequate prestimulation to induce oxytocin release and milk ejection while simultaneous milk flow is prevented. Journal of Dairy Science, 100 (10), 8609–8613. doi: https://doi.org/10.3168/jds.2017-12937

- Odorčić, M., Rasmussen, M. D., Paulrud, C. O., Bruckmaier, R. M. (2019). Review: Milking machine settings, teat condition and milking efficiency in dairy cows. Animal, 13, s94–s99. doi: https://doi.org/10.1017/s1751731119000417

- Paliy, A., Aliiev, E., Paliy, A., Ishchenko, K., Lukyanov, I., Dobrovolsky, V. et al. (2021). Revealing changes in the technical parameters of the teat cup liners of milking machines during testing and production conditions. EUREKA: Physics and Engineering, 6, 102–111. doi: https://doi.org/10.21303/2461-4262.2021.002056

- Nørstebø, H., Rachah, A., Dalen, G., Rønningen, O., Whist, A. C., Reksen, O. (2018). Milk-flow data collected routinely in an automatic milking system: an alternative to milking-time testing in the management of teat-end condition? Acta Veterinaria Scandinavica, 60 (1). doi: https://doi.org/10.1186/s13028-018-0356-x

- Paliy, A. P. (2016). Modern aspects of operation liner teat cups. Scientific Messenger of LNU of Veterinary Medicine and Biotechnologies, 18 (2). doi: https://doi.org/10.15421/nvlvet6736

- Palii, А. P., Handola, Yu. M., Shevchenko, I. O., Stotskyi, A. O., Stotskyi, O. G., Sereda, A. I. et al. (2020). Assessment of cow lactation and milk parameters when applying various milking equipment. Ukrainian Journal of Ecology, 10 (4), 195–201. Available at: https://www.ujecology.com/articles/assessment-of-cow-lactation-and-milk-parameters-when-applying-various-milking-equipment.pdf

- Aliiev, E. B. (2011). Teoretychne doslidzhennia vplyvu tekhnichnykh parametriv doilnoi ustanovky na shvydkist molokoviddachi. Visnyk Kharkivskoho Natsionalnoho tekhnichnoho universytetu silskoho hospodarstva imeni Petra Vasylenka: Suchasni problemy vdoskonalennia tekhnichnykh system i tekhnolohiy u tvarynnytstvi, 108, 92–98. Available at: http://aliev.in.ua/doc/stat/2011/stat_1.pdf

- Moon, B., Lee, J., Park, S., Seok, C.-S. (2018). Study on the Aging Behavior of Natural Rubber/Butadiene Rubber (NR/BR) Blends Using a Parallel Spring Model. Polymers, 10 (6), 658. doi: https://doi.org/10.3390/polym10060658

- Penry, J. F., Upton, J., Leonardi, S., Thompson, P. D., Reinemann, D. J. (2018). A method for assessing teatcup liner performance during the peak milk flow period. Journal of Dairy Science, 101 (1), 649–660. doi: https://doi.org/10.3168/jds.2017-12942

- Paliy, A., Nanka, A., Marchenko, M., Bredykhin, V., Paliy, A., Negreba, J. et al. (2020). Establishing changes in the technical parameters of nipple rubber for milking machines and their impact on operational characteristics. Eastern-European Journal of Enterprise Technologies, 2 (1 (104)), 78–87. doi: https://doi.org/10.15587/1729-4061.2020.200635

- Vtoryi, V. F., Vtoryi, S. V. (2020). Diagnostic method of milking systems using digital technologies. Taurida herald of the agrarian sciences, 4 (24), 20–28. doi: https://doi.org/10.33952/2542-0720-2020-4-24-20-28

- Shkromada, O., Skliar, O., Pikhtirova, A., Inessa, G. (2019). Pathogens transmission and cytological composition of cow’s milk. Acta Veterinaria Eurasia, 45, 73–79. doi: https://doi.org/10.26650/actavet.2019.19004

- Paliy, A., Aliiev, E., Nanka, A., Bogomolov, O., Bredixin, V., Paliy, A. et al. (2021). Identifying changes in the technical parameters of milking rubber under industrial conditions to elucidate their effect on the milking process. Eastern-European Journal of Enterprise Technologies, 3 (1 (111)), 21–29. doi: https://doi.org/10.15587/1729-4061.2021.231917

- Gálik, R., Boďo Š Staroňová, L. (2016). Monitoring the inner surface of teat cup liners made from different materials. Research in Agricultural Engineering, 61, S74–S78. doi: https://doi.org/10.17221/50/2015-rae

- ISO 1817:2022. Rubber, vulcanized or thermoplastic – Determination of the effect of liquids. Available at: https://www.iso.org/standard/79904.html

- ISO 37:2017. Rubber, vulcanized or thermoplastic – Determination of tensile stress-strain. Available at: https://www.iso.org/standard/68116.html

- ISO 815-2:2019. Rubber, vulcanized or thermoplastic – Determination of compression set – Part 2: At low temperatures. Available at: https://www.iso.org/standard/74944.html

- Lee, S. Y., Eom, S. B., Won, J. S., Bae, J. W., Park, S. H., Lee, S. G. (2021). Evaluation of Aging Behavior of Nitrile Butadiene Rubbers via Oxygen-consumption Experiments. Fibers and Polymers, 22 (3), 639–646. doi: https://doi.org/10.1007/s12221-021-0345-y

- Aliiev, E., Paliy, A., Kis, V., Milenin, A., Ishchenko, K., Paliy, A. et al. (2022). Justifying parameters for the automatic servo control system of a rotary plate vacuum pump in the milking machine. Eastern-European Journal of Enterprise Technologies, 4 (1 (118)), 80–89. doi: https://doi.org/10.15587/1729-4061.2022.262215

- Aliiev, E. B. (2010). Doslidzhennia spratsovanosti diynoi humy doilnoho aparatu z urakhuvanniam teoriyi starinnia na osnovi ploskoi zadachi. Zbirnyk naukovykh prats IMT NAAN “Mekhanizatsiya, ekolohizatsiya ta konvertatsiya biosyrovyny u tvarynnytstvi”, 1 (5,6), 233–242. Available at: http://aliev.in.ua/doc/stat/2010/stat_3.pdf

- Fahim, A., Kamboj, M. L., Sirohi, A. S., Bhakat, M., Prasad, S., Gupta, R. (2018). Milking machine induced teat reactions in crossbred cows milked in automated herringbone milking parlour. The Indian Journal of Animal Sciences, 88 (12), 1412–1415. doi: https://doi.org/10.56093/ijans.v88i12.85809

- Dmytriv, V., Dmytriv, I., Lavryk, Y., Horodeckyy, I. (2018). Models of adaptation of the milking machines systems. BIO Web of Conferences, 10, 02004. doi: https://doi.org/10.1051/bioconf/20181002004

- Wieland, M., Virkler, P. D., Borkowski, A. H., Älveby, N., Wood, P., Nydam, D. V. (2019). An observational study investigating the association of ultrasonographically assessed machine milking-induced changes in teat condition and teat-end shape in dairy cows. Animal, 13 (2), 341–348. doi: https://doi.org/10.1017/s1751731118001246

- Tse, C., Barkema, H. W., DeVries, T. J., Rushen, J., Pajor, E. A. (2018). Impact of automatic milking systems on dairy cattle producers’ reports of milking labour management, milk production and milk quality. Animal, 12 (12), 2649–2656. doi: https://doi.org/10.1017/s1751731118000654

- Wang, J., Lovarelli, D., Rota, N., Shen, M., Lu, M., Guarino, M. (2022). The Potentialities of Machine Learning for Cow-Specific Milking: Automatically Setting Variables in Milking Machines. Animals, 12 (13), 1614. doi: https://doi.org/10.3390/ani12131614

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Andriy Paliy, Elchyn Aliiev, Anatoliy Paliy, Katerina Ishchenko, Ivan Rybalko, Olena Pavlichenko, Mikola Prihodko, Vjacheslav Popsui, Larisa Bondarchuk, Tetyana Chernyavskaya

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.