Створення методики визначення інтенсивності випарування вологи при вакуумному сушінні фруктів

DOI:

https://doi.org/10.15587/1729-4061.2023.273709Ключові слова:

коефіцієнт опору випаровуванню, випаровування вологи, активність води, вакуумне сушіння, ультразвукАнотація

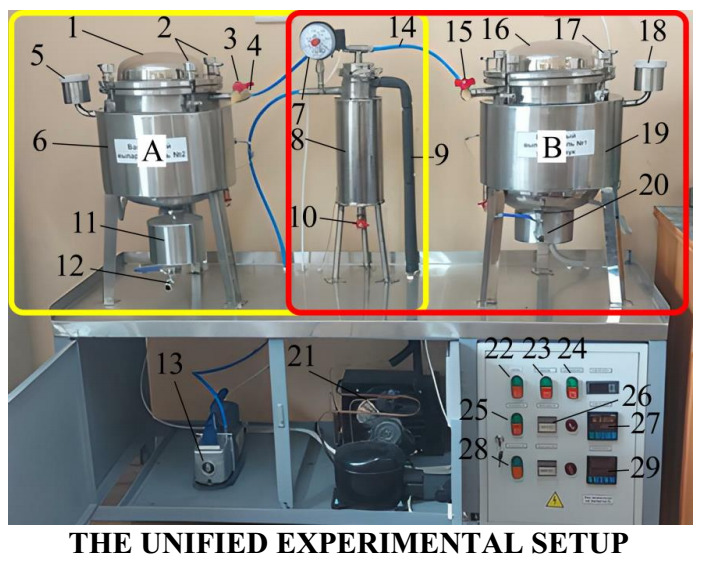

Об’єктами дослідження були сорти яблуні селекції Республіки Казахстан: «Байтерек», «Саркит» і «Сая», а також сорти груші: «Силик», «Жаздик» і «Нагіма». Суттєве значення в збереженні харчової цінності має вивчення процесу випаровування вологи при вакуумній сушінні плодів. В основному, випаровуваність продукту характеризується коефіцієнтом опору випаровуванню ‒ µ. Також під час відведення вологи змінюється термодинамічний стан вологи, що описується показником активності води ‒ aw. Експериментальне визначення цих параметрів дозволяє проаналізувати випаровування вологи в процесі вакуумного сушіння. Дослідженнями встановлено такі коефіцієнти випаровування: µ=2,03±0,07 для сортів яблук і µ=2,3±0,05 для сортів груш. Або активність води знижується з 1,0 до 0,62±0,01 для сортів яблук і з 1,0 до 0,65±0,04 для сортів груш. Виявлено два періоди сушіння. Перший період сушіння: 5,45–6,10 год для сортів яблук; та 6.12–6.25 год. для сортів груші. Тривалість другого періоду сушіння: 4,15–3,50 год для сортів яблук; і 4,35–4,48 год для сортів груші. Критична вологість: 27,1±2,1 % для сортів яблук; і 30,1±2,5 % для сортів груші. Порівняльний аналіз розрахункових та експериментальних даних показує максимальні відхилення 22,5 % для сортів яблуні та 23 % для сортів груші. Запропоноване рівняння для розрахунку швидкості випаровування вологи з урахуванням властивостей продукту та гігроскопічних параметрів повітря може бути використане на практиці для дослідження динаміки випаровування вологи з поверхні продукту. Результати досліджень дозволяють підібрати оптимальний режим вакуумного сушіння сортів яблук і груш з метою збереження харчової цінності та виробництва біологічно активних добавок для харчової промисловості

Спонсор дослідження

- The authors gratefully acknowledge the “Ministry of Agriculture of the Republic of Kazakhstan” for the financial support of the research project “Development of technology for processing promising varieties of fruit, berry crops and grapes of domestic selection in order to obtain biologically active substances and fruit and berry powders for use in the food industry” within the framework of Programme Targeted Funding No. BR10764977.

Посилання

- Shingisov, A. U., Alibekov, R. S., Yerkebayeva, S. U., Mailybayeva, E. U., Kadeyeva, M. S. (2022). Study of the polyphenols content in the various apples sorts of the Kazakhstan selection. News of the National Academy of Sciences of the Republic of Kazakhstan, Series Chemistry and Technology, 2 (451), 169–179. Available at: https://journals.nauka-nanrk.kz/chemistry-technology/article/view/3116/3285

- Alibekov, R. S., Utebaeva, A. A., Nurseitova, Z. T., Konarbayeva, Z. K., Khamitova, B. M. (2021). Cottage cheese fortified by natural additives. Food Research, 5 (S1), 152–159. doi: https://doi.org/10.26656/fr.2017.5(s1).013

- Shingisov, A. U., Alibekov, R. S., Yerkebayeva, S. U., Gabrilyants, E. A., Tastemirova, U. U. (2022). Vacuum Drying of Apple, Pear and Raspberry Varieties Growing in the Southern Regions of the Republic of Kazakhstan. The Journal of Almaty Technological University, 4, 19–25. doi: https://doi.org/10.48184/2304-568x-2022-4-19-25

- Radojčin, M., Pavkov, I., Bursać Kovačević, D., Putnik, P., Wiktor, A., Stamenković, Z. et al. (2021). Effect of Selected Drying Methods and Emerging Drying Intensification Technologies on the Quality of Dried Fruit: A Review. Processes, 9 (1), 132. doi: https://doi.org/10.3390/pr9010132

- Liu, Y., Sabadash, S., Duan, Z., Deng, C. (2022). The influence of different drying methods on the quality attributes of beetroots. Eastern-European Journal of Enterprise Technologies, 3 (11 (117)), 60–68. doi: https://doi.org/10.15587/1729-4061.2022.258049

- Lim, J., Taip, F. S., Ab Aziz, N., Ibrahim, M. N., How, M. S. (2021). Effects of drying methods on the physicochemical properties of powder made from different parts of pumpkin. Food Research, 5 (S1), 160–167. doi: https://doi.org/10.26656/fr.2017.5(s1).058

- Shingisov, A. U. (2010). Scientific and practical bases for improving the technique and technology of vacuum-freeze drying of national fermented milk products [Nauchno-prakticheskie osnovy sovershenstvovanija tehniki i tehnologii vakuum-sublimacionnoy sushki nacional'nyh kislomolochnyh produktov]. Semei, 424.

- Burova, N., Kislitsina, N., Gryazina, F., Pashkova, G., Kuzminykh, A. (2017). A review of techniques for drying food products in vacuum drying plants and methods for quality control of dried samples (Technical note). Revista Espacios, 38 (52). Available at: https://www.revistaespacios.com/a17v38n52/a17v38n52p35.pdf

- Shingisov, A. U., Alibekov, R. S. (2016). Analysis of the moisture evaporation process during vacuum freeze-drying of koumiss and shubat. Heat and Mass Transfer, 53 (5), 1571–1578. doi: https://doi.org/10.1007/s00231-016-1920-4

- Islam Shishir, M. R., Taip, F. S., Aziz, N. Ab., Talib, R. A., Hossain Sarker, Md. S. (2016). Optimization of spray drying parameters for pink guava powder using RSM. Food Science and Biotechnology, 25 (2), 461–468. doi: https://doi.org/10.1007/s10068-016-0064-0

- Tastemirova, U., Mukhtarkhanova, R., Alimardanova, M., Alibekov, R., Shingisov, A. (2022). Impact of vacuum freeze-drying on the reconstituted camel milk composition. Food Science and Technology, 42. doi: https://doi.org/10.1590/fst.61722

- Gaman, L. V., Shtannikov, A. V., Isaev, D. I. (2019). On the question of the method for determining the amount of evaporation from the surfaces of freshwater ice and snow in the conditions of the high-latitude Arctic [K voprosu o metodike opredeleniya velichiny ispareniya s poverhnostey presnovodnogo l'da i snega v usloviyah vysokoshirotnoy Arktiki]. In Problems of the Arctic region. Proceedings of the XVIII International Scientific Conference of Students and Postgraduates. Murmansk, 45–51.

- Erlihman, V. N., Fatyhov, Y. A. (2018). Methodology for calculating the rate of drying of a food product depending on the activity of water in the processes of refrigeration technology [Metodika rascheta skorosti usushki pishhevogo produkta v zavisimosti ot aktivnosti vody v processah holodil'noy tehnologii]. Bulletin of the International Academy of Refrigeration, 4, 10–14.

- Gusak, A. V., Krasnova, A. A., Filippov, V. I. (2017). Freezing shrinkage of multi-layer semi-finished products [Usushka pri zamorazhivanii mnogoslojnyh polufabrikatov]. New technologies, 3, 32–37.

- Pakhomov, A. N., Gatapova, N. T., Pakhomova, Yu. V. (2016). Modeling and calculation of the kinetics of drying liquid dispersed products on substrates [Modelirovanie i raschet kinetiki sushki zhidkih dispersnyh produktov na podlozhkah]. Tomsk, 160.

- Sen, N. Т., Nurgmanov, А. H., Arabova, Z. M., Nugmanova, А. А. (2019). Calculation of energy for the evaporation of bound moisture from a jackfruit [Vychislenie energii na isparenie svyazannoy vlagi iz dzhekfruta]. News of KSTU, 55, 214–225.

- Nadi, F., Tzempelikos, D. (2018). Vacuum drying of apples (cv. Golden Delicious): drying characteristics, thermodynamic properties, and mass transfer parameters. Heat and Mass Transfer, 54 (7), 1853–1866. doi: https://doi.org/10.1007/s00231-018-2279-5

- Dondokova, S. A., Bitueva, E. B., Antipov, A. V. (2016). The use of freeze drying in the production of meat products [Ispol’zovaniye sublimatsionnoy sushki v proizvodstve myasnykh produktov]. Scientific Review. Technical science [Nauchnoe obozrenie. Tehnicheskie nauki], 4, 37–48.

- Kremenevskaya, M. I. (2019). Scientific foundations of technologies for deep processing of collagen-containing raw materials to obtain products with desired properties [Nauchnye osnovy tehnologiy glubokoy pererabotki kollagensoderzhashhego syr'ya dlya polucheniya produktov s zadannymi svoystvami]. Moscow, 34.

- Nowak, D., Lewicki, P. P. (2004). Infrared drying of apple slices. Innovative Food Science & Emerging Technologies, 5 (3), 353–360. doi: https://doi.org/10.1016/j.ifset.2004.03.003

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2023 Azret Shingisov, Ravshanbek Alibekov, Victoriia Evlash, Saparkul Yerkebayeva, Elvira Mailybayeva, Ukilim Tastemirova

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.