Optimization of cross-section dimensions of structural members made of cold-formed profiles using compromise search

DOI:

https://doi.org/10.15587/1729-4061.2022.261037Keywords:

cold-formed profile, load-carrying capacity, flexural-torsional buckling, post-buckling behavior, parametric optimizationAbstract

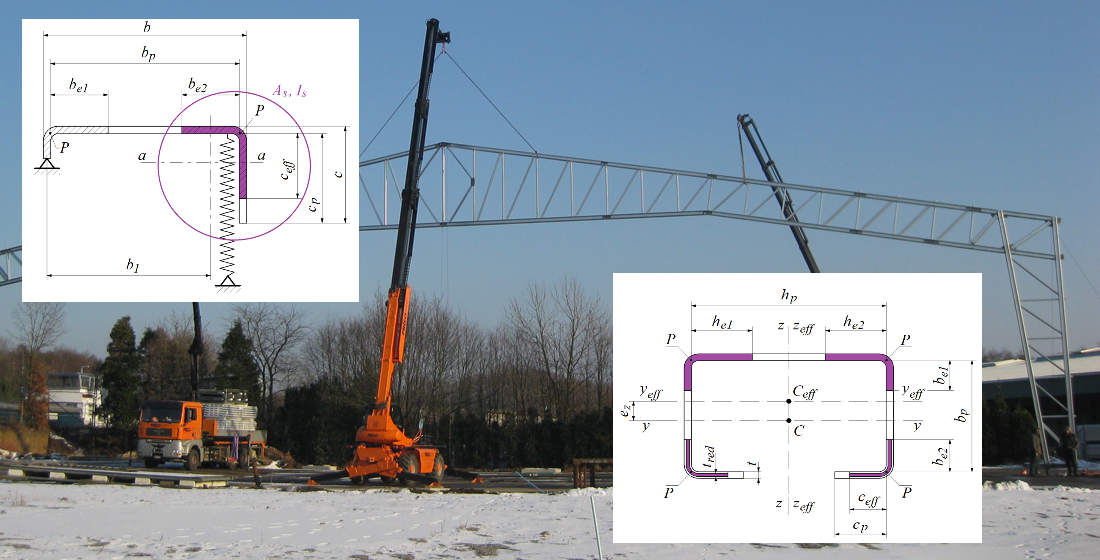

The object of this study is a structural member made from a C-shaped cold-formed profile, investigated to search for optimal cross-sectional dimensions. The parametric optimization task is stated as the problem to find the optimal cross-sectional dimensions of the structural member under axial compression conditions, taking into account its post-buckling behavior (local buckling of the web and flanges, as well as a distortional buckling of the cross-section) and structural requirements. In this case, the material consumption and mechanical characteristics of steel, as well as the design lengths of the structural member, were considered constant and predefined. The considered criterion of optimality was the maximization of the load-carrying capacity of the structural member for the overall buckling under the axial compression. The stated optimization problem is solved using the method of exhaustive search while applying the developed software. Additionally, for fixed steel consumption, compromise solutions were searched that do not depend on the thickness of the profile and the design lengths of the structural member. The resulting cold-formed C-shaped profiles with optimal cross-sectional dimensions are characterized by a higher load-carrying capacity for the overall buckling under axial compression (to 24.45 % and 22.19 %) at the same steel consumption compared to the profiles offered by the manufacturer. Analysis of the reported results made it possible to devise recommendations for optimal ratios of dimensions and geometric characteristics of the structural members made from C-shaped profiles operating under axial compression. The ratios could be used both at the stage of selection of cross-sections of structural members from cold-formed profiles, and in the development of effective assortments of cold-formed profiles

References

- Bilyk, S., Yurchenko, V. (2020). Size optimization of single edge folds for cold-formed structural members. Strength of Materials and Theory of Structures, 105, 73–86. doi: https://doi.org/10.32347/2410-2547.2020.105.73-86

- Yurchenko, V. (2019). Algorithm for shear flows in arbitrary cross-sections of thin-walled bars. Magazine of Civil Engineering, 8 (92), 3–26. doi: https://doi.org/10.18720/MCE.92.1

- Mojtabaei, S. M., Becque, J., Hajirasouliha, I. (2021). Structural Size Optimization of Single and Built-Up Cold-Formed Steel Beam-Column Members. Journal of Structural Engineering, 147 (4). doi: https://doi.org/10.1061/(asce)st.1943-541x.0002987

- Leng, J. (2016). Optimization techniques for structural design of cold-formed steel structures. Recent Trends in Cold-Formed Steel Construction, 129–151. doi: https://doi.org/10.1016/b978-0-08-100160-8.00006-2

- Ye, J., Hajirasouliha, I., Becque, J., Pilakoutas, K. (2016). Development of more efficient cold-formed steel channel sections in bending. Thin-Walled Structures, 101, 1–13. doi: https://doi.org/10.1016/j.tws.2015.12.021

- Gatheeshgar, P., Poologanathan, K., Gunalan, S., Shyha, I., Tsavdaridis, K. D., Corradi, M. (2020). Optimal design of cold-formed steel lipped channel beams: Combined bending, shear, and web crippling. Structures, 28, 825–836. doi: https://doi.org/10.1016/j.istruc.2020.09.027

- Leng, J., Li, Z., Guest, J. K., Schafer, B. W. (2014). Shape optimization of cold-formed steel columns with fabrication and geometric end-use constraints. Thin-Walled Structures, 85, 271–290. doi: https://doi.org/10.1016/j.tws.2014.08.014

- Wang, B., Gilbert, B. P., Guan, H., Teh, L. H. (2016). Shape optimisation of manufacturable and usable cold-formed steel singly-symmetric and open columns. Thin-Walled Structures, 109, 271–284. doi: https://doi.org/10.1016/j.tws.2016.10.004

- Parastesh, H., Hajirasouliha, I., Taji, H., Bagheri Sabbagh, A. (2019). Shape optimization of cold-formed steel beam-columns with practical and manufacturing constraints. Journal of Constructional Steel Research, 155, 249–259. doi: https://doi.org/10.1016/j.jcsr.2018.12.031

- Ma, W., Becque, J., Hajirasouliha, I., Ye, J. (2015). Cross-sectional optimization of cold-formed steel channels to Eurocode 3. Engineering Structures, 101, 641–651. doi: https://doi.org/10.1016/j.engstruct.2015.07.051

- Yurchenko, V., Peleshko, I. (2021). Methodology for solving parametric optimization problems of steel structures. Magazine of Civil Engineering, 107 (7), 10705. doi: https://doi.org/10.34910/MCE.107.5

- Yurchenko, V., Peleshko, I., Biliaiev, N. (2021). Application of gradient projection method to parametric optimization of steel lattice portal frame. International Journal for Computational Civil and Structural Engineering, 17 (3), 132–156. doi: https://doi.org/10.22337/2587-9618-2021-17-3-132-156

- Moharrami, M., Louhghalam, A., Tootkaboni, M. (2014). Optimal folding of cold formed steel cross sections under compression. Thin-Walled Structures, 76, 145–156. doi: https://doi.org/10.1016/j.tws.2013.11.009

- Lee, J., Kim, S.-M., Park, H.-S., Woo, B.-H. (2005). Optimum design of cold-formed steel channel beams using micro Genetic Algorithm. Engineering Structures, 27 (1), 17–24. doi: https://doi.org/10.1016/j.engstruct.2004.08.008

- EN 1993-1-3:2006: EuroCode 3: Design of steel structures - Part 1-3: General rules – Supplementary rules for cold-formed members and sheeting. Available at: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1993.1.3.2006.pdf

- EN 1993-1-5:2006: EuroCode 3: Design of steel structures - Part 1-5: General rules – Plated structural elements. Available at: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1993.1.5.2006.pdf

- EN 1993-1-1:2005: EuroCode 3: Design of steel structures - Part 1-1: General rules and rules for buildings. Available at: https://standards.iteh.ai/catalog/standards/cen/482fb48f-4de9-4e00-91eb-f0c09b3f4b87/en-1993-1-1-2005

- Perelmuter, A., Kriksunov, E., Gavrilenko, I., Yurchenko, V. (2010). Designing bolted end-plate connections in compliance with Eurocode and Ukrainian codes: consistency and contradictions. Selected papers of the 10th International Conference “Modern Building Materials, Structures and Techniques”, 733–743. Available at: https://www.researchgate.net/publication/266038627_Designing_bolted_end-plate_connections_in_compliance_with_eurocode_and_ukrainian_codes_Consistency_and_contradictions

- Karpilovsky, V., Kriksunov, E., Perelmuter, A., Yurchenko, V. (2021). Analysis and design of structural steel joints and connection: software implementation. International Journal for Computational Civil and Structural Engineering, 17 (2), 58–66. doi: https://doi.org/10.22337/2587-9618-2021-17-2-57-65

- UTSSS-014-16. Sortament kholodnoformovannykh profiley dlya legkikh stal'nykh tonkostennykh konstruktsiy proizvoditeley Ukrainy. Ukrainskiy Tsentr Stal'nogo Stroitel'stva. Available at: https://uscc.ua/uploads/section/Files/sortament-holodnoformovannyh-profilej-dlya-lstk-new2020.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Vitalina Yurchenko, Ivan Peleshko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.