Application of paper mill sludge and additional chemical substances in the production of container cardboard

DOI:

https://doi.org/10.15587/1729-4061.2022.265112Keywords:

fiber sludge, container cardboard, wastepaper processing, flocculant, Praestol, Percol, PoliminAbstract

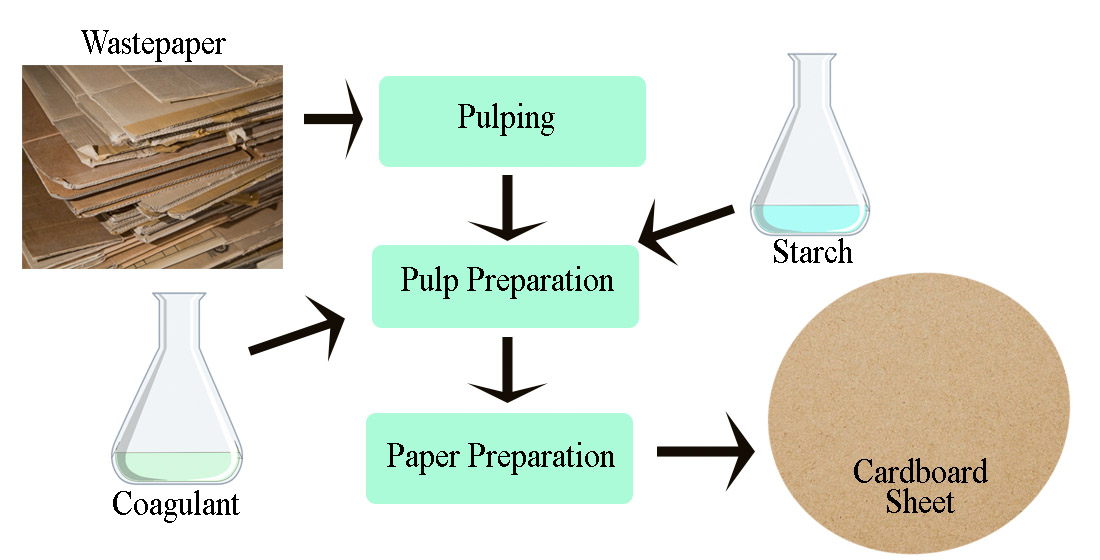

The possibility to dispose of paper mill sludge as part of a composition of container cardboard from secondary raw materials has been investigated. The fractional composition of the sludge was studied and it was shown that the main part of the fibers is represented by small particles with a size of up to 1.2 mm. Studying the processes of formation of container cardboard when using paper mill sludge showed that an increase in the consumption of fibrous-inorganic waste leads to a deterioration in the physical and mechanical properties of cardboard. However, the increase in sludge consumption does not affect the surface absorption of water during one-sided wetting. The value of these indicators is within the normal range and is 25 and 70 g/m2, respectively. In addition, an increase in sludge consumption from 10 to 50 % in the manufacture of cardboard leads to a decrease in the degree of fiber retention on the grid from 86.3 to 82.1 %. Regularities of using strengthening additives, namely industrial cationic and anionic flocculants, as well as native corn and modified starches for the strength of cardboard and the quality of sub-grid waters, have been established. Research results show that the effect of flocculants is quite ambiguous. On the one hand, there is a clearly observed positive impact on the quality of the sub-grid waters. This is due to the reduction of their turbidity due to smaller fiber washes. Nevertheless, the positive effect on physical and mechanical parameters is minimal, and in some cases, there is a decrease in strength indicators. The greater the efficiency of keeping fine fiber on the grid when using flocculants, the lower the values of physical and mechanical indicators. In general, when using sludge in the composition of cardboard in combination with flocculants and starch, the indicators were achieved that are considered standard for waste paper container cardboard of grade KT-1 according to TU U 17.1-41085075-002:2017

References

- Liu, M., Tan, S., Zhang, M., He, G., Chen, Z., Fu, Z., Luan, C. (2020). Waste paper recycling decision system based on material flow analysis and life cycle assessment: A case study of waste paper recycling from China. Journal of Environmental Management, 255, 109859. doi: https://doi.org/10.1016/j.jenvman.2019.109859

- Abdollahbeigi, M. (2020). An overview of the paper recycling process in Iran. Journal of Chemical Reviews, 3 (1), 1–19. doi: https://doi.org/10.22034/JCR.2021.118054

- Yang, X., Berglund, L. A. (2019). Recycling without Fiber Degradation – Strong Paper Structures for 3D Forming Based on Nanostructurally Tailored Wood Holocellulose Fibers. ACS Sustainable Chemistry & Engineering, 8 (2), 1146–1154. doi: https://doi.org/10.1021/acssuschemeng.9b06176

- Meyer, T., Amin, P., Allen, D. G., Tran, H. (2018). Dewatering of pulp and paper mill biosludge and primary sludge. Journal of Environmental Chemical Engineering, 6 (5), 6317–6321. doi: https://doi.org/10.1016/j.jece.2018.09.037

- Hovey, G., Allen, D. G., Tran, H. (2017). Drying characteristics of biosludge from pulp and paper mills. TAPPI Journal, 16 (08), 465–473. doi: https://doi.org/10.32964/tj16.8.465

- Tawalbeh, M., Rajangam, A. S., Salameh, T., Al-Othman, A., Alkasrawi, M. (2021). Characterization of paper mill sludge as a renewable feedstock for sustainable hydrogen and biofuels production. International Journal of Hydrogen Energy, 46 (6), 4761–4775. doi: https://doi.org/10.1016/j.ijhydene.2020.02.166

- Zhang, L., Li, W., Lu, J., Li, R., Wu, Y. (2021). Production of platform chemical and bio-fuel from paper mill sludge via hydrothermal liquefaction. Journal of Analytical and Applied Pyrolysis, 155, 105032. doi: https://doi.org/10.1016/j.jaap.2021.105032

- Frías, M., Rodríguez, O., Sánchez de Rojas, M. I. (2015). Paper sludge, an environmentally sound alternative source of MK-based cementitious materials. A review. Construction and Building Materials, 74, 37–48. doi: https://doi.org/10.1016/j.conbuildmat.2014.10.007

- Starokadomsky, D., Halysh, V., Starokadomska, A., Nikolaychuk, A., Shulga, S., Sigareva, N. (2020). Restorative biocompatible polymer composites on the base of epoxy-resin filled by surface-modified disperse utilizated solid waste of industrial paper products. Journal of Applied Surfaces and Interfaces, 8 (1-3). doi: https://doi.org/10.48442/IMIST.PRSM/jasi-v8i1-3.23321

- Soucy, J., Koubaa, A., Migneault, S., Riedl, B. (2014). The potential of paper mill sludge for wood–plastic composites. Industrial Crops and Products, 54, 248–256. doi: https://doi.org/10.1016/j.indcrop.2014.01.013

- Fahim, S., Nisar, N., Ahmad, Z., Asghar, Z., Said, A., Atif, S. et. al. (2018). Managing Paper and Pulp Industry By-Product Waste Utilizing Sludge as a Bio-Fertilizer. Polish Journal of Environmental Studies, 28 (1), 83–90. doi: https://doi.org/10.15244/pjoes/83614

- Deykun, I., Halysh, V., Barbash, V. (2018). Rapeseed straw as an alternative for pulping and papermaking. Cellulose Chemistry and Technology, 52 (9-10), 833–839. Available at: https://www.cellulosechemtechnol.ro/pdf/CCT9-10(2018)/p.833-839.pdf

- Adamopoulos, S., Passialis, C., Voulgaridis, E., Oliver Villanueva, J. V. (2014). Grammage and structural density as quality indexes of packaging grade paper manufactured from recycled pulp. Drewno: prace naukowe, doniesienia, komunikaty, 57 (191), 145–151. doi: https://doi.org/10.12841/wood.1644-3985.053.11

- Pandey, N., Thakur, C. (2020). Study on treatment of paper mill wastewater by electrocoagulation and its sludge analysis. Chemical Data Collections, 27, 100390. doi: https://doi.org/10.1016/j.cdc.2020.100390

- Todorova, D. A., Bencheva, S. P. (2015). Investigation on the influence of chemical additives over the behavior of paper furnish from recycled newspaper fiber material. Bulgarian Chemical Communications, 47, 45–50.

- Kuňa, V., Balberčák, J., Opálená, E., Pažitný, A., Russ, A., Schwartz, J. (2016). The effect of multi-component retention systems on the properties of the paper suspensions. Wood Research, 61 (5), 767–776.

- Peretz, R., Mamane, H., Wissotzky, E., Sterenzon, E., Gerchman, Y. (2020). Making Cardboard and Paper Recycling More Sustainable: Recycled Paper Sludge For Energy Production and Water-Treatment Applications. Waste and Biomass Valorization, 12 (3), 1599–1608. doi: https://doi.org/10.1007/s12649-020-01117-y

- Veluchamy, C., Raju, V. W., Kalamdhad, A. S. (2018). Electrohydrolysis pretreatment for enhanced methane production from lignocellulose waste pulp and paper mill sludge and its kinetics. Bioresource Technology, 252, 52–58. doi: https://doi.org/10.1016/j.biortech.2017.12.093

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Vita Halysh, Inna Trus, Iaroslav Radovenchyk, Tetyana Shabliy, Anna Ivanchenko, Alina Nikolaichuk, Nikolai Gomelya

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.