Determining the thermoplastic deformation mechanism of titanium reduction reactors and recommendations to increase the reactor service life

DOI:

https://doi.org/10.15587/1729-4061.2022.265577Keywords:

titanium sponge, titanium tetrachloride reduction reactor, reactor thermoplastic deformation process simulation, finite-element methodAbstract

The object of research reported in this paper is the stressed-strained state of reactors when producing titanium sponge by the magnesium thermal method, taking into consideration the conditions of their operation and the physical and mechanical properties of the materials.

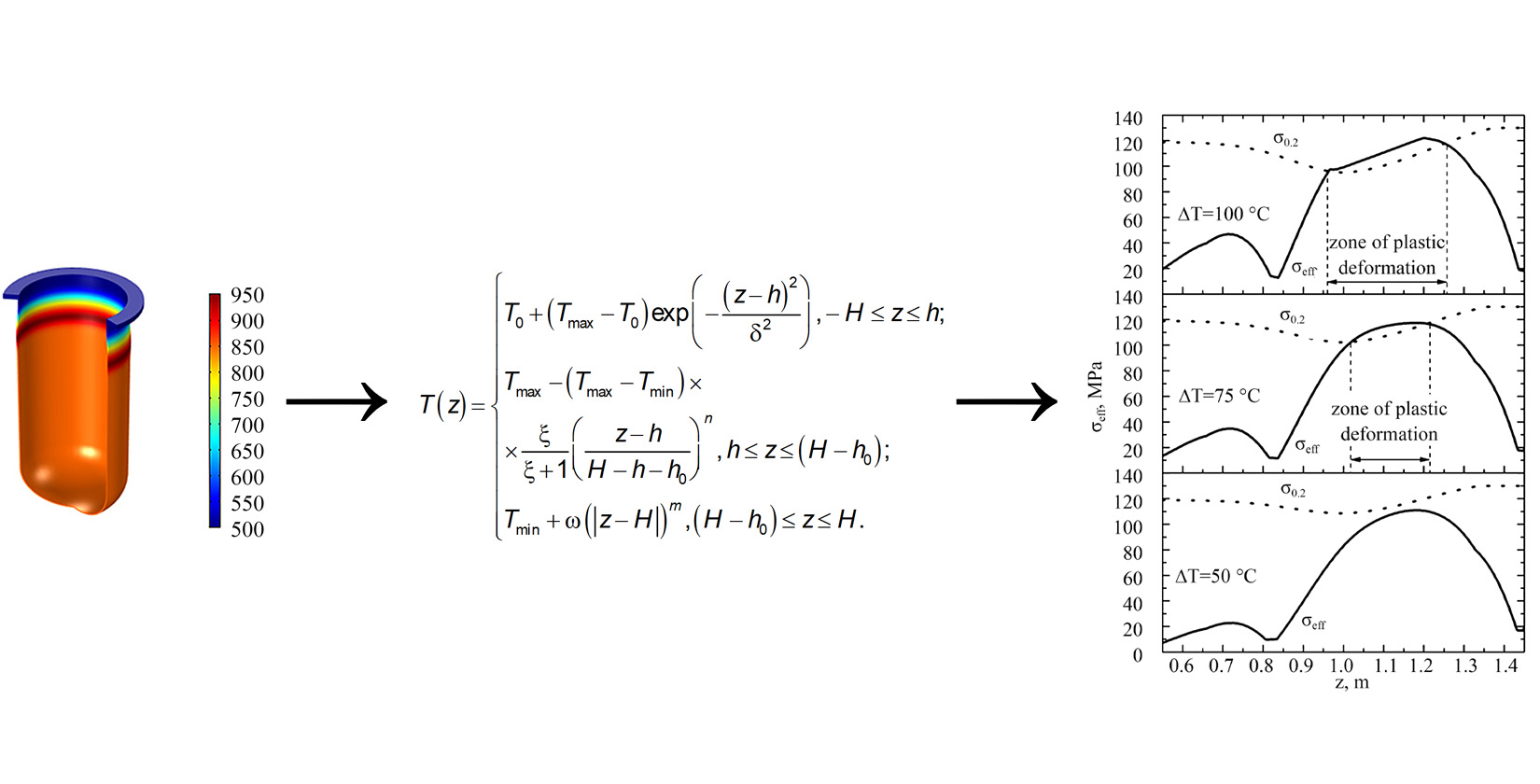

The problem considered is the plastic deformation of the reactor in the process of reducing titanium tetrachloride. To solve this task, an axisymmetric geometric model of the reactor was built using a CAD module of the Comsol Multiphysics software package. For the calculation, the Nonlinear Structural Materials module was used. Owing to the method of finite elements, the critical parameters for the formation of the plastic deformation band of the reactor were determined.

Modeling the process of thermoplastic deformation of the reactor under the conditions of obtaining titanium sponge has made it possible to determine the temperature gradient in the upper part of the reactor wall, which leads to local plastic deformation of the wall. The solution to the problem of continuing the reactor service would be to prevent overheating (overcooling) of the reactor wall within the resulting temperature. The physical and mechanical parameters of the material of the reactor wall, necessary to prevent the occurrence of an annular band of plastic deformation, have also been determined. It was shown that at ∆T˃∆Tcrit=60 °C, the walls of a 10-ton reactor during the reduction of titanium tetrachloride with magnesium perceive plastic deformation whose maximum value can reach

Deformation mechanisms that lead to a change in the shape of the side wall of reactors of magnesium-thermal production of sponge titanium under the action of a heterogeneous temperature field have been determined. The proposed technological solutions are to eliminate local changes in diameter in the upper part of the reactor wall. This will make it possible not only to increase the life of the reactors but will reduce the flow of alloy components into the titanium sponge of nickel, chromium, and iron

References

- Mishchenko, V. H., Yevsieieva, N. O. (2012). Vplyv povzuchosti metalu na termin ekspluatatsii reaktoriv mahniietermichnoho vyrobnytstva tytanu. Fizyko-khimichna mekhanika materialiv, 2, 119–122.

- Tytan hubchastyi. Available at: https://ztmc.zp.ua/uk/титан-губчастий/ Last accessed: 11.04.2022

- Tekhnolohiia vyrobnytstva tytanovoi hubky. Available at: https://ztmc.zp.ua Last accessed:16.05.2022

- Mamutova, A. T., Ultarakova, A. A., Kuldeev, E. I., Esengaziev, A. M. (2018). Modern condition and proposed solutions for processing chloride waste of titanium-magnesium production. Complex Use of Mineral Resources/Mineraldik Shikisattardy Keshendi Paidalanu, 307 (4), 173–180. doi: https://doi.org/10.31643/2018/6445.44

- Tankeev, V. P., Riaposov, Iu. A., Rymkevich, D. A. (2009). Stanovlenie i razvitie proizvodstva gubchatogo titana v gorode Berezniki. Titan, 2 (24), 4–7.

- Myshchenko, V. H., Tverdokhleb, S. V., Omelchenko, O. S. (2004). Razvytye razrushenyia apparatov vosstanovlenyia y prymesy v hubchatom tytane. Visnyk dvyhunobuduvannia, 3, 135–137.

- Putina, A. O., Kochergin, V. P., Nechaev, N. P. (1984). Izmenenie svoistv stali 12Kh18N10T v protcesse ekspluatatcii v magnietermicheskom proizvodstve i ee zashchita. Zashchita metallov, 20 (5), 772–775.

- Fuwa, A., Takaya, S. (2005). Producing titanium by reducing TiCl2-MgCl2 mixed salt with magnesium in the molten state. JOM, 57 (10), 56–60. doi: https://doi.org/10.1007/s11837-005-0153-7

- Mishchenko, V. G., Evseeva, N. A. (2012). Polzuchest kak opredeliaiushchii faktor uvelicheniia sroka ekspluatatcii reaktorov magnietermicheskogo proizvodstva titana. Fіziko-khіmіchna mekhanіka materіalіv, 48 (2), 119–122.

- Shejko, S., Sukhomlin, G., Mishchenko, V., Shalomeev, V., Tretiak, V. (2018). Formation of the Grain Boundary Structure of Low-Alloyed Steels in the Process of Plastic Deformatio. Materials Science and Technology Conference and Exhibition 2018, MS and T 2018, 1, 746–753. doi: https://doi.org/10.7449/2018/mst_2018_746_753

- Sposoby proizvodstva iz poroshkovogo titana. Available at: https://extxe.com/5918/sposoby-proizvodstva-iz-poroshkovogo-titana/ Last accessed: 08.05.2022

- Sidorenko, S. A. (2017). Аbout the complex processing of chloride waste from the titanium tetrachloride production. Іntellectual potential of the xxi century. Intellectual potential of the XXI century ‘2017. Available at: https://www.sworld.education/konferu7-317/74.pdf

- Comsol Multiphysics-programnaia sreda. Available at: https://www.comsol.com/products Last accessed: 29.05.2022

- Lunov, V. V., Bielikov, S. B., Ulitenko, O. M., Yevsieieva, N. O. (2011). Fizyko-matematychna model ta alhorytm rozrakhunku teplofizychnykh protsesiv tverdinnia zlyvka u vylyvnytsi. Teoryia y praktyka metallurhyy, 1-2, 26–32.

- Kobayashi, S., Oh, S., Altan, T. (1989). Metalforming and the Finite-Element Method. Oxford University Press, 377. doi: http://doi.org/10.1093/oso/9780195044027.001.0001

- Jiang, Z., Xie, H. (2018). Application of Finite Element Analysis in Multiscale Metal Forming Process. Finite Element Method – Simulation, Numerical Analysis and Solution Techniques. doi: https://doi.org/10.5772/intechopen.71880

- Golovanov, A. P., Tiuleneva, O. N., Shigabutdinov, A. F. (2006). Metod konechnykh elementov v statike i dinamike tonkostennykh konstruktcii. Moscow: Mir, 392.

- Rumiantcev, A. V. (1995). Metod konechnykh elementov v zadachakh teploprovodnosti. Kaliningradskii Gosudarstvennyi Universitet, 170.

- Hot and corrosion-resistant steel (2010). Pat. Application Publication Pub.: No. US 2010/0008813 A1 Pub. Date: 14.01.2010.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Valeriy Mishchenko, Stephan Loskutov, Alona Kripak

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.