Influence of the mold type on the mechanical properties of the piston alloy with nano alumina in casting and metal mold

DOI:

https://doi.org/10.15587/1729-4061.2022.266263Keywords:

casting-mold, mechanical-properties, piston-alloy, alumina, sand-casting, powder, ductile, fracture, hardness, grainAbstract

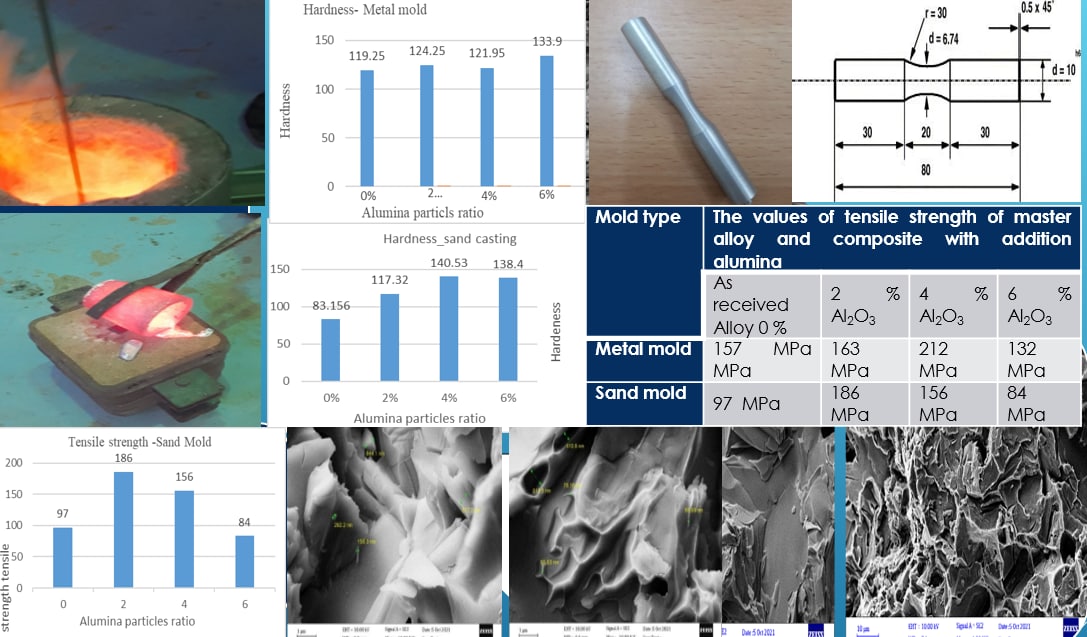

This research is an experimental comparison study to show the influence of mold type casting on mechanical properties. The study considers the aluminum alloy of a gasoline engine piston with nanoparticles alumina Al2O3 size 25 nm manufactured in two types of molds. Sand mold and cast-iron mold were selected to cast the aluminum composite components. A systematic comparative study of tensile strength and hardness properties of cast aluminum components is made on sand and metal molds production. The nano powder can add to enhance the mechanical properties must not exceed 4 % for metal and sand mold casting. According to data for hardness, adding nano alumina powder has minimal impact on metal mold casting, but it significantly improves sand casting. From a financial standpoint, metal casting provides higher economic values for making piston aluminum castings. The hardness rises as the alumina content does in two molds as compared to the obtained specimen. It demonstrates that the highest hardness occurs at 4 % alumina in the sand-casting mold and at 6 % alumina in the metal. When the compositions of the casting materials are the same, a comparison of the fracture morphology between sand and mold casting reveals more ductile fractures for metal molds compared to brittle fractures in sand cast by large silicon separation grains because of higher grain growth in sand casting by longer solidification time. The same is seen in mold casting, which exhibits reduced ductility due to the alumina nanoparticles' dispersion strengthening process in the aluminum matrix. This arises as a result of nano alumina dispersion acting as barriers to dislocation motions in the aluminum matrix, enhancing strength but reducing ductility.

Supporting Agency

- The authors would like to thank the training and workshop center for the help to do the experments in the casting workshop.

References

- Javidani, M., Larouche, D. (2014). Application of cast Al–Si alloys in internal combustion engine components. International Materials Reviews, 59 (3), 132–158. doi: https://doi.org/10.1179/1743280413y.0000000027

- Samal, P., Babu, D. M., Kiran, S. V., Surekha, B., Vundavilli, P. R., Mandal, A. (2020). Study of Microstructural and Machining Characteristics of Hypereutectic Al-Si Alloys Using Wire-EDM for Photovoltaic Application. Silicon, 13 (12), 4407–4419. doi: https://doi.org/10.1007/s12633-020-00742-5

- Faraji, M., Yousefzadeh, S., Nassar, M. F., Zahra, M. M. A. (2022). MnCo2O4/N-doped graphene quantum dot vigorously coupled to MXene nanosheet: A bifunctional Oxygen electrocatalyst outperforms Pt/IrO2 benchmark electrocatalysts in metal-air batteries. Journal of Alloys and Compounds, 927, 167115. doi: https://doi.org/10.1016/j.jallcom.2022.167115

- Ali, M., Alshalal, I., Al Zubaidi, F. N., Yousif, A. R. (2020). Improvement of Corrosion and Erosion Resistance Properties for Cast Iron. IOP Conference Series: Materials Science and Engineering, 881 (1), 012068. doi: https://doi.org/10.1088/1757-899x/881/1/012068

- Baghani, A., Davami, P., Varahram, N., Shabani, M. O. (2014). Investigation on the Effect of Mold Constraints and Cooling Rate on Residual Stress During the Sand-Casting Process of 1086 Steel by Employing a Thermomechanical Model. Metallurgical and Materials Transactions B, 45 (3), 1157–1169. doi: https://doi.org/10.1007/s11663-013-0015-6

- Jadayil, W. M. A. (2011). Studying the effects of varying the pouring rate on the casting defects using nondestructive testing techniques. JJMIE, 5 (6), 521–526. Available at: http://jjmie.hu.edu.jo/files/v5n6/JJMIE%20-207-10.pdf

- Ali, M., Alshalal, I., Abtan, A. A., Yousif, A. R., Mohmmed, J. H. (2021). Effect of nano-sized SiO2 particles addition on the surface roughness and micro hardness of copper-based friction materials. Journal of Mechanical Engineering Research and Developments, 44 (2), 104–111. Available at: https://jmerd.net/Paper/Vol.44,No.2(2021)/104-111.pdf

- Al-Furjan, M. S. H., Hajmohammad, M. H., Shen, X., Rajak, D. K., Kolahchi, R. (2021). Evaluation of tensile strength and elastic modulus of 7075-T6 aluminum alloy by adding SiC reinforcing particles using vortex casting method. Journal of Alloys and Compounds, 886, 161261. doi: https://doi.org/10.1016/j.jallcom.2021.161261

- Salur, E., Acarer, M., Şavkliyildiz, İ. (2021). Improving mechanical properties of nano-sized TiC particle reinforced AA7075 Al alloy composites produced by ball milling and hot pressing. Materials Today Communications, 27, 102202. doi: https://doi.org/10.1016/j.mtcomm.2021.102202

- Rashnoo, K., Sharifi, M. J., Azadi, M., Azadi, M. (2020). Influences of reinforcement and displacement rate on microstructure, mechanical properties and fracture behaviors of cylinder-head aluminum alloy. Materials Chemistry and Physics, 255, 123441. doi: https://doi.org/10.1016/j.matchemphys.2020.123441

- Ibrahim Al-Zuhairi, H. M., Hamza, A. K., Mahdi, B. S., Al-Alkawi, H. J. M. (2020). Effect of Heat Treatment on Toughness and Fatigue Behavior Strength of Steel CK45. IOP Conference Series: Materials Science and Engineering, 881 (1), 012069. doi: https://doi.org/10.1088/1757-899x/881/1/012069

- Baumeister, G., Okolo, B., Rögner, J. (2008). Microcasting of Al bronze: influence of casting parameters on the microstructure and the mechanical properties. Microsystem Technologies, 14 (9-11), 1647–1655. doi: https://doi.org/10.1007/s00542-008-0605-4

- Sajjadi, S. A., Ezatpour, H. R., Torabi Parizi, M. (2012). Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Materials & Design, 34, 106–111. doi: https://doi.org/10.1016/j.matdes.2011.07.037

- Lal, S., kumar, A., Kumar, S., Gupta, N. (2021). Characterization of A356/B4C composite fabricated by electromagnetic stir-casting process with vacuum. Materials Today: Proceedings, 34, 832–841. doi: https://doi.org/10.1016/j.matpr.2020.05.830

- Fialko, N., Dinzhos, R., Sherenkovskii, J., Meranova, N., Prokopov, V., Babak, V. et al. (2022). Influence on the thermophysical properties of nanocomposites of the duration of mixing of components in the polymer melt. Eastern-European Journal of Enterprise Technologies, 2 (5 (116)), 25–30. doi: https://doi.org/10.15587/1729-4061.2022.255830

- Al-Zuhairi, H. M. I., Alshalal, I. (2020). Enhancement of Mechanical Properties of Aluminum Piston Alloy Using Al2O3 Material. 2020 6th International Engineering Conference “Sustainable Technology and Development" (IEC). doi: https://doi.org/10.1109/iec49899.2020.9122921

- Khenyab, A. Y., Abed, R. M., Hassan, A. R., Al-Alkawi, H. J. M. (2022). Improving the property of wear rate and hardness by adding hybrid nanomaterials to AA7075. Eastern-European Journal of Enterprise Technologies, 2 (12 (116)), 30–36. doi: https://doi.org/10.15587/1729-4061.2022.255331

- Mae, H., Teng, X., Bai, Y., Wierzbicki, T. (2008). Comparison of ductile fracture properties of aluminum castings: Sand mold vs. metal mold. International Journal of Solids and Structures, 45 (5), 1430–1444. doi: https://doi.org/10.1016/j.ijsolstr.2007.10.016

- Fauzi, A., Lalasari, L. H., Sofyan, N., Ferdiansyah, A., Dhaneswara, D., Yuwono, A. H. (2022). Synthesis of titanium dioxide nanotube derived from ilmenite mineral through post-hydrothermal treatment and its photocatalytic performance. Eastern-European Journal of Enterprise Technologies, 2 (12 (116)), 15–29. doi: https://doi.org/10.15587/1729-4061.2022.255145

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Haitham Mohammed, Iqbal Alshalal, Auday Awad, Baha Sami, Muna Khalil

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.