Increasing energy efficiency and enabling the process of vacuum mode stabilization during the operation of milking equipment

DOI:

https://doi.org/10.15587/1729-4061.2022.267799Keywords:

machine milking, milking equipment, vacuum system, pulsation rate, nipple rubber, resource forecastingAbstract

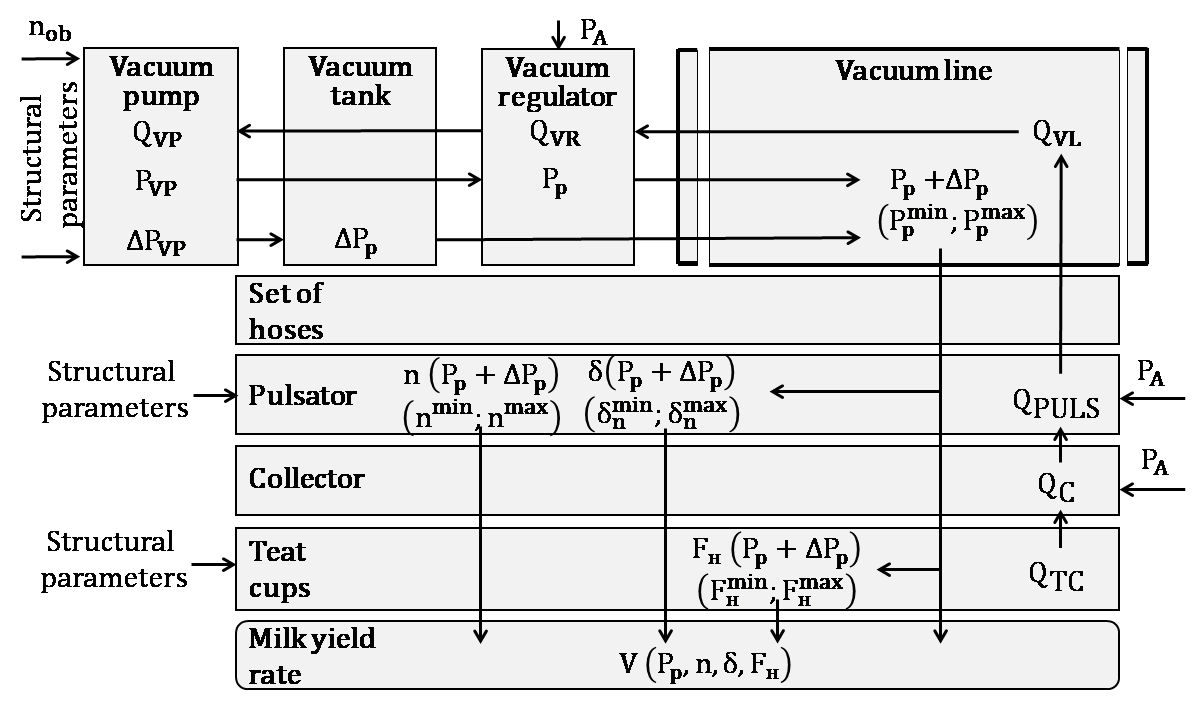

A scientific hypothesis has been put forward, according to which an increase in the efficiency of using a vacuum system of milking equipment with an upper milk line with mechanical pulsators can be achieved by predicting its residual resource. As well as with the subsequent planning of maintenance and the identification of patterns and dependences characterizing these processes.

As a result of experimental studies of changes in the technical and technological parameters of the vacuum system of milking equipment with an upper milk line with mechanical pulsators, the theoretical dependences obtained with their correlation coefficient r=0.971–0.972 were empirically confirmed. Namely, the magnitude of the working vacuum, the pulsation rate, the ratio of pulsations, and the tension force of the nipple rubber, depending on the time of operation. It was established that after 175 hours of operation of the milking stationary installation, the value of the working vacuum decreased by 4 %, the pulsation frequency – 14 %, the ratio of pulsations – 16 %, and the tension force of nipple rubber – 21 %.

On the basis of the obtained dependences included in the procedure for forecasting the resource of the vacuum system of milk-milking equipment with an upper milk line with mechanical pulsators, the software package «Alt viewer 1.0» was developed. It is designed to display and automatically process the measurement results of the technical and technological parameters of milking equipment using the designed Tester of milking machines, v.2.0. The software performs the following main functions: reading the measurement results from the memory card, decoding them, displaying them in tabular and graphical forms. As well as the calculation of the parameters of pulsations and the formation of a report, forecasting the resource of the nodes of the vacuum system. The program also provides for the storage of information on the calibration coefficients of pressure sensors, air flow meter, as well as the frequency of polling sensors when measuring pulsations and fluctuations of the working vacuum

References

- Vtoryi, V. F., Vtoryi, S. V. (2020). Diagnostic method of milking systems using digital technologies. Taurida herald of the agrarian sciences, 4 (24), 20–28. doi: https://doi.org/10.33952/2542-0720-2020-4-24-20-28

- Aliiev, E., Paliy, A., Kis, V., Milenin, A., Ishchenko, K., Paliy, A. et al. (2022). Justifying parameters for the automatic servo control system of a rotary plate vacuum pump in the milking machine. Eastern-European Journal of Enterprise Technologies, 4 (1 (118)), 80–89. doi: https://doi.org/10.15587/1729-4061.2022.262215

- Kucheruk, V., Palamarchuk, Y., Kulakov, P., Gnes, T. (2014). The statistical model of mechanical milking duration of farmyard milking installation. Eastern-European Journal of Enterprise Technologies, 2 (4 (68)), 31–37. doi: https://doi.org/10.15587/1729-4061.2014.23120

- Enokidani, M., Shinozuka, Y., Kawai, K. (2019). Analysis of results from 21 years of milking system inspections in Japanese dairy farms. Animal Science Journal, 91 (1). doi: https://doi.org/10.1111/asj.13315

- Paliy, A. P. (2019). Doslidzhennia roboty pulsatoriv doilnykh aparativ ta vplyv yikh robochykh parametriv na pokaznyky molokovyvedennia u koriv. Ahrarna nauka ta kharchovi tekhnolohiyi, 3 (106), 83–90.

- Lutsenko, M., Halai, O., Legkoduh, V., Lastovska, I., Borshch, O., Nadtochii, V. (2021). Milk production process, quality and technological properties of milk for the use of various types of milking machines. Acta Scientiarum. Animal Sciences, 43, e51336. doi: https://doi.org/10.4025/actascianimsci.v43i1.51336

- Paliy, A., Aliiev, E., Paliy, A., Ishchenko, K., Lukyanov, I., Dobrovolsky, V. et al. (2021). Revealing changes in the technical parameters of the teat cup liners of milking machines during testing and production conditions. EUREKA: Physics and Engineering, 6, 102–111. doi: https://doi.org/10.21303/2461-4262.2021.002056

- Abdel-Hamid, S. El., Fattah, D. M. A., Ghanem, H. M., Manaa, E. A.-A. (2017). Temperament during Milking Process and its Effect on Behavioral, Productive Traits and Biochemical Parameters in Friesian Dairy Cows. Advances in Animal and Veterinary Sciences, 5 (12). doi: https://doi.org/10.17582/journal.aavs/2017/5.12.508.513

- Náglová, Z., Rudinskaya, T. (2021). Factors Influencing Technical Efficiency in the EU Dairy Farms. Agriculture, 11 (11), 1114. doi: https://doi.org/10.3390/agriculture11111114

- Tse, C., Barkema, H. W., DeVries, T. J., Rushen, J., Pajor, E. A. (2018). Impact of automatic milking systems on dairy cattle producers’ reports of milking labour management, milk production and milk quality. Animal, 12 (12), 2649–2656. doi: https://doi.org/10.1017/s1751731118000654

- Aliiev, E., Paliy, A., Dudin, V., Kis, V., Paliy, A., Ostapenko, V. et al. (2022). Establishing an interconnection between the technical and technological parameters of milking equipment based on the movement of a milk-air mixture in a milking machine. Eastern-European Journal of Enterprise Technologies, 2 (1 (116)), 35–46. doi: https://doi.org/10.15587/1729-4061.2022.253978

- Kubina, Ľ., Kováč, Š. (2002). Decreasing energetic demands of vacuum pumps being used in machine milking with utilization of a frequency convertor. Res. Agr. Eng., 48, 103–111.

- Aliiev, E., Paliy, A., Kis, V., Paliy, A., Petrov, R., Plyuta, L. et al. (2022). Establishing the influence of technical and technological parameters of milking equipment on the efficiency of machine milking. Eastern-European Journal of Enterprise Technologies, 1 (1 (115)), 44–55. doi: https://doi.org/10.15587/1729-4061.2022.251172

- Odorčić, M., Rasmussen, M. D., Paulrud, C. O., Bruckmaier, R. M. (2019). Review: Milking machine settings, teat condition and milking efficiency in dairy cows. Animal, 13, s94–s99. doi: https://doi.org/10.1017/s1751731119000417

- Nørstebø, H., Rachah, A., Dalen, G., Rønningen, O., Whist, A. C., Reksen, O. (2018). Milk-flow data collected routinely in an automatic milking system: an alternative to milking-time testing in the management of teat-end condition? Acta Veterinaria Scandinavica, 60 (1). doi: https://doi.org/10.1186/s13028-018-0356-x

- Meyer, D., Haeussermann, A., Hartung, E. (2021). Relationship between dairy cows' hind leg activity and vacuum records during milking. Animal, 15 (4), 100186. doi: doi: https://doi.org/10.1016/j.animal.2021.100186

- Stauffer, C., Feierabend, M., Bruckmaier, R. M. (2020). Different vacuum levels, vacuum reduction during low milk flow, and different cluster detachment levels affect milking performance and teat condition in dairy cows. Journal of Dairy Science, 103 (10), 9250–9260. doi: https://doi.org/10.3168/jds.2020-18677

- Paliy, A., Aliiev, E., Nanka, A., Bogomolov, O., Bredixin, V., Paliy, A. et al. (2021). Identifying changes in the technical parameters of milking rubber under industrial conditions to elucidate their effect on the milking process. Eastern-European Journal of Enterprise Technologies, 3 (1 (111)), 21–29. doi: https://doi.org/10.15587/1729-4061.2021.231917

- Tuor, M., Jenni, B., Wellnitz, O., Bruckmaier, R. M. (2022). Reduced liner-open phase and vacuum instead of prestimulation increase parlor efficiency in dairy cows. Journal of Dairy Science, 105 (2), 1533–1541. doi: https://doi.org/10.3168/jds.2021-21170

- Aliiev, E. B. (2011). Teoretychne doslidzhennia vplyvu tekhnichnykh parametriv doilnoi ustanovky na shvydkist molokoviddachi. Visnyk Kharkivskoho Natsionalnoho tekhnichnoho universytetu silskoho hospodarstva imeni Petra Vasylenka: Suchasni problemy vdoskonalennia tekhnichnykh system i tekhnolohiy u tvarynnytstvi, 108, 92–98. Available at: http://aliev.in.ua/doc/stat/2011/stat_1.pdf

- Besier, J., Bruckmaier, R. M. (2016). Vacuum levels and milk-flow-dependent vacuum drops affect machine milking performance and teat condition in dairy cows. Journal of Dairy Science, 99 (4), 3096–3102. doi: https://doi.org/10.3168/jds.2015-10340

- Reinemann, D. J., van den Borne, B. H. P., Hogeveen, H., Wiedemann, M., Paulrud, C. O. (2021). Effects of flow-controlled vacuum on milking performance and teat condition in a rotary milking parlor. Journal of Dairy Science, 104 (6), 6820–6831. doi: https://doi.org/10.3168/jds.2020-19418

- Kucheruk, V., Palamarchuk, Y., Kulakov, P. (2014). The statistical models of machinery milking duration by group milking machines. Eastern-European Journal of Enterprise Technologies, 4 (4 (70)), 13–17. doi: https://doi.org/10.15587/1729-4061.2014.26287

- Dmytriv, V. T., Dmytriv, I. V., Horodetskyy, I. M., Yatsunskyi, P. P. (2020). Adaptive cyber-physical system of the milk production process. INMATEH Agricultural Engineering, 61 (2), 199–208. doi: https://doi.org/10.35633/inmateh-61-22

- Paliy, A., Aliiev, E., Paliy, A., Ishchenko, K., Shkromada, O., Musiienko, Y. et al. (2021). Development of a device for cleansing cow udder teats and testing it under industrial conditions. Eastern-European Journal of Enterprise Technologies, 1 (1 (109)), 43–53. doi: https://doi.org/10.15587/1729-4061.2021.224927

- Medvedskyi, O., Achkevych, O., Achkevych, V. (2019). Dynamics of the vacuummetric pressure of the dairy chamber of the collector of milking machine. Scientific Horizons, 5 (78), 51–57. doi: https://doi.org/10.33249/2663-2144-2019-78-5-51-57

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Andriy Paliy, Elchyn Aliiev, Anatoliy Paliy, Viktor Kis, Artur Levkin, Yana Kotko, Iruna Levchenko, Maryna Shkurko, Sofiia Svysenko, Vitalii Sevastianov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.