Determination of heat transfer mechanisms during vacuum drying of solid-moist and liquid-viscous materials

DOI:

https://doi.org/10.15587/1729-4061.2022.268241Keywords:

vacuum drying, heat transfer mechanism, heat transfer shares, Jerusalem artichoke tubers, camel milk, mare milkAbstract

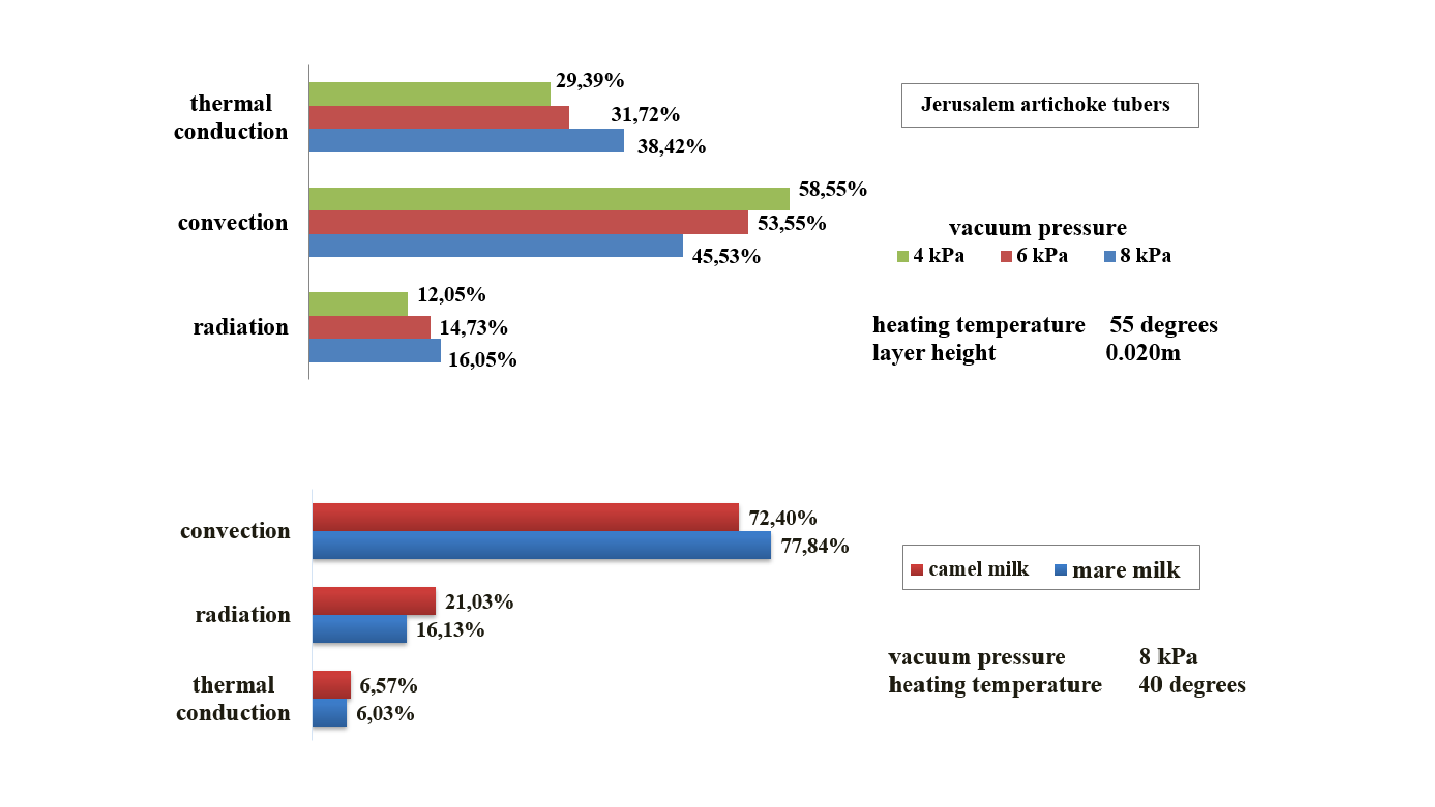

Most drying methods combine convective, conductive and radiation heat transfer processes. The share of each type of heat transfer may vary depending on the type and mode of drying, type of product, etc. In this study, the problem of determining the heat transfer mechanism of vacuum drying of solid-moist and liquid-viscous materials is solved. The objects of the study are Jerusalem artichoke tubers, camel and mare milk. The numerical values of the heat transfer components are found experimentally and their shares in the total heat flux are determined. During vacuum drying of Jerusalem artichoke at a medium pressure of 4 kPa and a temperature of 55 °C (with a layer height of 0.01 and 0.02 m), the convective component predominates (58.55 and 67.65 %). The share of thermal conduction (18.96 and 29.39 %) and radiation (13.39 and 12.05 %) is much lower. The mechanism of thermal conduction begins to prevail with an increase in the height of the material layer (0.03 and 0.04 m). The convective component is also dominant for vacuum drying of milk: at medium pressures of 6÷10 kPa and a temperature of 40 °C, its value for mare milk reaches 78.21 %, for camel milk – 73.33 %. The second most important is the share of radiation (19.45 and 22.58 %). Conductive heat transfer has the minimum indicators (5.66 and 6.17 %). The large values of the share of thermal conduction during drying of Jerusalem artichoke compared to milk are explained by the fact that heat transfer occurs inside the tubers due to conduction, and inside milk – due to convection. Insignificant shares of radiation are explained by low and medium vacuum values in the chamber. In the studied range, heat and mass transfer occurs due to molecular diffusion and convection. The results obtained can be used to formulate criterion heat transfer equations, in engineering calculations, and optimization of the vacuum dryer operation.

References

- Demarchi, S. M., Torrez Irigoyen, R. M., Giner, S. A. (2018). Vacuum drying of rosehip leathers: Modelling of coupled moisture content and temperature curves as a function of time with simultaneous time-varying ascorbic acid retention. Journal of Food Engineering, 233, 9–16. doi: https://doi.org/10.1016/j.jfoodeng.2018.03.027

- Ustinova, M. E., Yashonkov, A. A. (2021). Experimental studies into the kinetics of the process of vacuum drying of carrot chips. IOP Conference Series: Earth and Environmental Science, 640 (2), 022011. doi: https://doi.org/10.1088/1755-1315/640/2/022011

- Lima, M. M. de, Tribuzi, G., Souza, J. A. R. de, Souza, I. G. de, Laurindo, J. B., Carciofi, B. A. M. (2016). Vacuum impregnation and drying of calcium-fortified pineapple snacks. LWT - Food Science and Technology, 72, 501–509. doi: https://doi.org/10.1016/j.lwt.2016.05.016

- Sun, D.-W. (Ed.) (2005). Thermal Food Processing: New Technologies and Quality Issues. CRC Press, 664. doi: https://doi.org/10.1201/9781420027372

- Rambhatla, S., Pikal, M. J. (2003). Heat and mass transfer scale-up issues during freeze-drying, I: Atypical radiation and the edge vial effect. AAPS PharmSciTech, 4 (2), 22–31. doi: https://doi.org/10.1208/pt040214

- Ratti, С.; Chen, X. D., Mujumdar, A. S. (Eds.) (2008). Freeze and vacuum drying of foods. Drying Technologies in Food Processing. Wiley-Blackwell, 225–251. Availavble at: https://www.wiley.com/en-us/Drying+Technologies+in+Food+Processing-p-9781405157636

- Delgado, J. M. P. Q., Barbosa de Lima, A. G. (Eds.) (2014). Transport Phenomena and Drying of Solids and Particulate Materials. Advanced Structured Materials. doi: https://doi.org/10.1007/978-3-319-04054-7

- Ganguly, A., Nail, S. L., Alexeenko, A. (2013). Experimental Determination of the Key Heat Transfer Mechanisms in Pharmaceutical Freeze-Drying. Journal of Pharmaceutical Sciences, 102 (5), 1610–1625. doi: https://doi.org/10.1002/jps.23514

- Ermolaev, V. A. (2021). The development of mathematical modelof low-temperature vacuum drying of cheeses. Bulletin of KSAU, 1 (166), 134–142. doi: https://doi.org/10.36718/1819-4036-2021-1-134-142

- Novikov, P. A. (1962). Vliyanie luchistoy sostavlyayuschey na kharakter teploobmena pri sublimatsii v vakuume. Inzhenerno-fizicheskiy zhurnal, 12 (5), 80–83.

- Smol'skiy, B. M., Novikov, P. A. (1961). O mekhanizme teplo- i massoobmena pri sublimatsii tel v razrezhennoy srede. Inzhenerno-fizicheskiy zhurnal, 11 (5), 41–47.

- Abdizhapparova, B. T., Khanzharov, N. S., Ospanov, B. O., Pankina, I. A., Orymbetova, G. E. (2019). A way of vacuum-atmospheric drying of jerusalem artichoke tubers. NEWS of National Academy of Sciences of the Republic of Kazakhstan, 6 (438), 165–176. doi: https://doi.org/10.32014/2019.2518-170x.167

- Abdizhapparova, B. T., Khanzharov, N. S., Ospanov, B. O., Pankina, I. A., Kamalbek, D. K., Akhmetov, Zh. M. (2019). Investigation of vacuum-atmospheric drying of camel and mare's milk. News of the national academy of sciences of the Republic of Kazakhstan. Series chemistry and technology, 6 (438), 55–60.doi: https://doi.org/10.32014/2019.2518-1491.74

- Barinov, I. N., Volkov, V. S. (2013). Chuvstvitel'nye elementy mikromekhanicheskikh datchikov davleniy. Osnovy proektirovaniya i razrabotki. Penza, 79.

- Latyshenko, K. P. (2016). Tekhnicheskie izmereniya i pribory. Moscow: Izdatel'stvo Yurayt.

- Radovanovic, A., Stojceska, V., Plunkett, A., Jankovic, S., Milovanovic, D., Cupara, S. (2015). The use of dry Jerusalem artichoke as a functional nutrient in developing extruded food with low glycaemic index. Food Chemistry, 177, 81–88. doi: https://doi.org/10.1016/j.foodchem.2014.12.096

- Dubkova, N., Kharkov, V., Vakhitov, M. (2021). Using Jerusalem artichoke powder in functional food production. Foods and Raw Materials, 9 (1), 69–78. doi: https://doi.org/10.21603/2308-4057-2021-1-69-78

- Yang, L., He, Q. S., Corscadden, K., Udenigwe, C. C. (2015). The prospects of Jerusalem artichoke in functional food ingredients and bioenergy production. Biotechnology Reports, 5, 77–88. doi: https://doi.org/10.1016/j.btre.2014.12.004

- Al-Juboori, A. T., Mohammed, M., Rashid, J., Kurian, J., El Refaey, S. (2013). Nutritional and medicinal value of camel (Camelus dromedarius) milk. Food and Environment II. doi: https://doi.org/10.2495/fenv130201

- Hussain, H., Wattoo, F. H., Wattoo, M. H. S., Gulfraz, M., Masud, T., Shah, I., Ali, S., Alavi, S. E. (2021). Camel milk as an alternative treatment regimen for diabetes therapy. Food Science & Nutrition, 9 (3), 1347–1356. doi: https://doi.org/10.1002/fsn3.2078

- Karpenya, M. M., Shlyakhtunov, V. I., Podrez, V. N. (2015). Tekhnologiya proizvodstva moloka i molochnykh produktov. Moscow: INFRA-M, 410.

- Pieszka, M., Łuszczyński, J., Zamachowska, M., Augustyn, R., Długosz, B., Hędrzak, M. (2016). Is mare milk an appropriate food for people? – a review. Annals of Animal Science, 16 (1), 33–51. doi: https://doi.org/10.1515/aoas-2015-0041

- Guo, L., Xu, W., Li, C., Ya, M., Guo, Y., Qian, J., Zhu, J. (2019). Production technology, nutritional, and microbiological investigation of traditionally fermented mare milk (Chigee) from Xilin Gol in China. Food Science & Nutrition, 8 (1), 257–264. doi: https://doi.org/10.1002/fsn3.1298

- Dmitriev, S. M., Khrobostov, A. E. (2012). Kratkiy kurs teplomassoobmena. Noviy Novgorod: NGTU, 144. Availavble at: https://obuchalka.org/20200823124019/kratkii-kurs-teplomassoobmena-dmitriev-s-m-hrobostov-a-e-2012.html

- Ginzburg, A. S., Gromov, M. A., Krasovskaya, G. I. (1980). Teplofizicheskie kharakteristiki pischevykh produktov. Moscow: Pischevaya promyshlennost', 288.

- Emissivity Values for Metals. Availavble at: https://www.flukeprocessinstruments.com/en-us/service-and-support/knowledge-center/infrared-technology/emissivity-metals

- Altukhov, I. V. Ochirov, V. D. (2010). Analiz metodov i sredstv opredeleniya opticheskikh i termoradiatsionnykh kharakteristik sakharosoderzhaschikh korneplodov. Vestnik AltGAU, 3, 68–72.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Bakhytkul Abdizhapparova, Volodymyr Potapov, Nurlan Khanzharov, Azret Shingissov, Bayan Khanzharova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.