Development of an untraditional technique to control the structure of the output flow from a vortex chamber

DOI:

https://doi.org/10.15587/1729-4061.2022.268516Keywords:

vortex chamber, thermoanemometer, control, vortex structure, speed profile, pulsation intensityAbstract

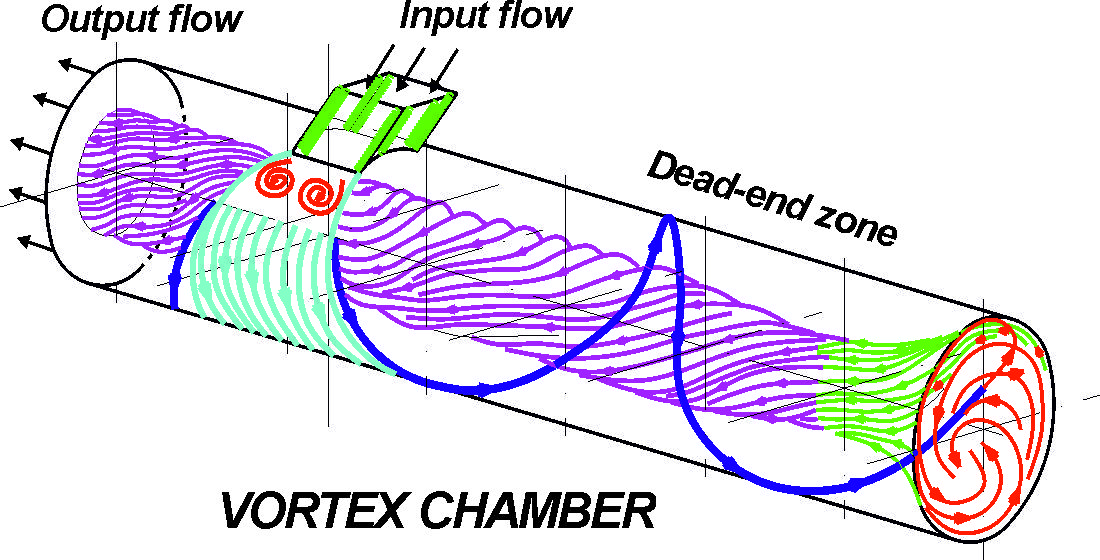

A technique of using coherent vortex formations of the dead-end zone of the vortex chamber of the end type as a controlling factor influencing the structure and characteristics of the output flow has been developed. The kinematic parameters of the flow relative to chambers with elongated and extremely short dead-end parts in the range of Reynolds numbers according to the parameters of the nozzle Re=47080–86530 were investigated. The reaction of the flow structure in the output sections of the vortex chambers was determined experimentally using thermoanemometry. Profiles of time-averaged transversal and axial velocity projections, as well as corresponding values of the relative intensity of velocity pulsations, were obtained. It was found that at Re=86530, the elongation of the dead-end part of the chamber leads to a decrease in the initial cross-section of the transversal component by 15 % with an increase in the axial component by 19.7 %, and, at Re=47080, to a decrease in the transversal component by 21 % with an increase in the axial component by 8.5 %. This indicates the redistribution of kinetic energy from transversal to axial energy motion, which is confirmed by the analysis of the corresponding intensity profiles of the velocity pulsations in the output section of the chamber in the near-wall and near-axis zones of the flow. The integral intensity of the velocity pulsations along the initial cross-section of comparable chamber designs increases in a chamber with an elongated dead-end part with almost no additional energy losses. The obtained results form the basis of a rational method of controlling the macro- and microstructure of flows, which determines the efficiency of mass exchange and heat exchange processes in vortex chambers of the end type. Such designs are characteristic of vortex mixers, burners of industrial furnaces, furnace devices of hot water and steam boilers, and other technological and power equipment

References

- Alekseenko, S. V., Kuybin, P. A., Okulov, V. L. (2005). Vvedenie v teoriyu kontsentrirovannykh vikhrey. Moscow-Izhevsk: Institut komp'yuternykh issledovaniy, 504.

- KHalatov, A. A., Avramenko, A. A., Shevchuk, I. V. (2000). Teploobmen i gidrodinamika v polyakh tsentrobezhnykh massovykh sil. Vol. 3. Kyiv: In-t tekhn. teplofiziki NAN Ukrainy, 474.

- Khalatov, A. A., Romanov, V. V., Borisov, I. I., Dashevskiy, Yu. Ya., Severin, S. D. (2010). Teploobmen i gidrodinamika v polyakh tsentrobezhnykh massovykh sil. Vol. 9. Kyiv: In-t tekhn. teplofiziki NAN Ukrainy, 474.

- Wormley, D. N. (1969). An Analytical Model for the Incompressible Flow in Short Vortex Chambers. Journal of Basic Engineering, 91 (2), 264–272. doi: https://doi.org/10.1115/1.3571091

- Babenko, V. V., Chun, H. H., Li, I. (2013). Boundary layer flow over elastic surfaces. Butterworth-Heinemann. doi: https://doi.org/10.1016/C2011-0-06221-X

- Babenko, V. (2021). Experimental Hydrodynamics for Flow Around Bodies. Academic Press. doi: https://doi.org/10.1016/C2019-0-04933-3

- Ferziger, J. H., Perić, M., Street, R. L. (2020). Computational methods for fluid dynamics. Springer, 614.

- Wei, X. G., Li, J., He, G. Q. (2018). Swirl Characteristics of Vortex Valve Variable-Thrust Solid Rocket Motor. Journal of Applied Fluid Mechanics, 11 (1), 205–215. doi: https://doi.org/10.29252/jafm.11.01.27658

- Wang, C., Zhao, J., Li, X. (2019). Effect of chamber diameter of vortex gripper on maximum suction force and flow field. Advances in Mechanical Engineering, 11 (3), 168781401983740. doi: https://doi.org/10.1177/1687814019837401

- Rogovyi, A., Korohodskyi, V., Khovanskyi, S., Hrechka, I., Medvediev, Y. (2021). Optimal design of vortex chamber pump. Journal of Physics: Conference Series, 1741 (1), 012018. doi: https://doi.org/10.1088/1742-6596/1741/1/012018

- Merzliakov, I., Pavlenko, I., Ochowiak, M., Ivanov, V., Agarwal, P. (2022). Flow Modeling in a Vortex Chamber of a Liquid–Steam Jet Apparatus. Processes, 10 (5), 984. doi: https://doi.org/10.3390/pr10050984

- Sharma, G., Majdalani, J. (2021). Effects of nozzle inlet size and curvature on the flow development in a bidirectional vortex chamber. Physics of Fluids, 33 (9), 093607. doi: https://doi.org/10.1063/5.0066121

- Sharma, G., Majdalani, J. (2022). Effects of various inlet parameters on the computed flow development in a bidirectional vortex chamber. Physics of Fluids, 34 (4), 043607. doi: https://doi.org/10.1063/5.0089443

- Babenko, V. V., Turick, V. N. (2008). Maket vikhrevykh struktur pri techenii potoka v vikhrevoy kamere. Prykladna hidromekhanika, 10 (82 (3)), 3–19.

- Turick, V., Kochin, V., Kochina, M. (2018). Examining the technique to control the structure of current in vortex chambers by wing vortex generators. Eastern-European Journal of Enterprise Technologies, 1 (5 (91)), 28–38. doi: https://doi.org/10.15587/1729-4061.2018.121962

- Marsden, Dzh. E., Chorin, A. (2004). Matematicheskie osnovy mekhaniki zhidkosti. Moscow-Izhevsk: NITS «Regulyarnaya i khaoticheskaya dinamika», 204.

- Chaplygin, S. A., Golubev, V. V. (1934). K teorii produvki tsilindrov dvigateley vnutrennego sgoraniya. Trudy TsAGI, 175, 3–46.

- Dyban, E. P., Epik, E. Ya. (1985). Teplomassoobmen i gidrodinamika turbulizirovannykh potokov. Kyiv: Nauk. dumka, 296.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Volodymyr Turyk, Viktor Kochin, Volodymyr Moroz, Dmytro Miliukov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.