Determining changes in the mineral composition of concrete due to chemical corrosion in a sulfate environment

DOI:

https://doi.org/10.15587/1729-4061.2022.268627Keywords:

sulfate technology, X-ray diffraction, thermoprogrammed mass spectrometry, X-ray fluorescence analysis, electron microscopyAbstract

The object of this study was the concrete structures of a chemical enterprise for the production of titanium dioxide. In this case, the ore is decomposed with sulfate acid according to the sulfate production technology. In an aggressive environment, chemical corrosion of concrete occurs, prolonged over time.

Using X-ray diffraction and X-ray fluorescence analysis methods, the mineral composition of two prototypes of concrete was determined. It was found that the sample obtained from the workshop for processing ore with sulfate acid showed an increased content of sulfur oxide (SO2) on the surface, by 33 %, with a reduced content of carbonates (CaCO3) on the surface, by 52.9 %, at a depth of 2 cm – by 53.65, compared to another (control) sample. At the same time, iron oxide (Fe2O3) was found on the surface in a sample of concrete from the ore storage room (control), the content of which decreased by 10.4 % at a depth of 2 cm, and by 12.4 % at a depth of 4 cm.

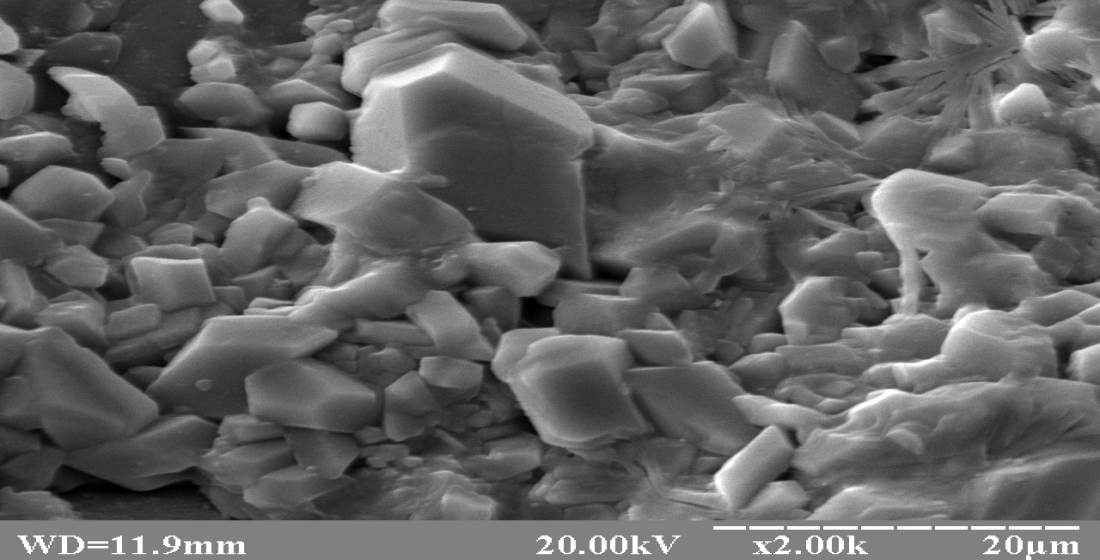

The results of electron microscopy show sulfur crystals on the surface of a concrete sample. It was also found that the microstructure of concrete was changed under the influence of sulfate corrosion, depending on the intensity of the exposure to a depth of 2 to 4 cm. By the method of thermoprogrammed mass spectrometry, it was established that when a sample of concrete exposed to sulfate acid is heated to a temperature of 400 °C, sulfur dioxide SO2 is released mainly from the surface. From the surface of the control sample, which contains a significant amount of CaCO3, which is easily destroyed by sulfate acid, there is probably a smaller amount of the product of thermal destruction of calcium carbonate carbon dioxide (CO2).

The results of the experiment can be used to study the mechanism of development of sulfate corrosion of concrete prolonged over time.

References

- Siryi, A. Yu. (2020). Vyrobnytstvo pihmentnoho dvookysu tytanu sulfatnym sposobom. Rozrobyty ta modernizuvaty vakuum-vyparnyi aparat dlia kontsentruvannia rozchynu tytanilsulfatu. Sumy: SumDU, 76. Available at: https://essuir.sumdu.edu.ua/handle/123456789/82160

- Niu, D., Lv, Y., Liu, X., Chen, L., Chen, G., Zhang, B. (2020). Study on the Sulfuration Mechanism of Concrete: Microstructure and Product Analysis. Materials, 13 (15), 3386. doi: https://doi.org/10.3390/ma13153386

- Shkromada, O., Paliy, A., Yurchenko, O., Khobot, N., Pikhtirova, A., Vysochin, I. et al. (2020). Influence of fine additives and surfactants on the strength and permeability degree of concrete. EUREKA: Physics and Engineering, 2, 19–29. doi: https://doi.org/10.21303/2461-4262.2020.001178

- Landa-Sánchez, A., Bosch, J., Baltazar-Zamora, M. A., Croche, R., Landa-Ruiz, L., Santiago-Hurtado, G. et al. (2020). Corrosion Behavior of Steel-Reinforced Green Concrete Containing Recycled Coarse Aggregate Additions in Sulfate Media. Materials, 13 (19), 4345. doi: https://doi.org/10.3390/ma13194345

- Zhou, Y., Tian, H., Sui, L., Xing, F., Han, N. (2015). Strength Deterioration of Concrete in Sulfate Environment: An Experimental Study and Theoretical Modeling. Advances in Materials Science and Engineering, 2015, 1–13. doi: https://doi.org/10.1155/2015/951209

- Zhao, G., Shi, M., Fan, H., Cui, J., Xie, F. (2020). The influence of multiple combined chemical attack on cast-in-situ concrete: Deformation, mechanical development and mechanisms. Construction and Building Materials, 251, 118988. doi: https://doi.org/10.1016/j.conbuildmat.2020.118988

- Li, X., O’Moore, L., Song, Y., Bond, P. L., Yuan, Z., Wilkie, S. et al. (2019). The rapid chemically induced corrosion of concrete sewers at high H2S concentration. Water Research, 162, 95–104. doi: https://doi.org/10.1016/j.watres.2019.06.062

- Marquez-Peñaranda, J. F., Sanchez-Silva, M., Husserl, J., Bastidas-Arteaga, E. (2015). Effects of biodeterioration on the mechanical properties of concrete. Materials and Structures, 49 (10), 4085–4099. doi: https://doi.org/10.1617/s11527-015-0774-4

- Stawiski, B., Kania, T. (2019). Examining the Distribution of Strength across the Thickness of Reinforced Concrete Elements Subject to Sulphate Corrosion Using the Ultrasonic Method. Materials, 12 (16), 2519. doi: https://doi.org/10.3390/ma12162519

- Shkromada, O., Fotina, T., Petrov, R., Nagorna, L., Bordun, O., Barun, M. et al. (2021). Development of a method of protection of concrete floors of animal buildings from corrosion at the expense of using dry disinfectants. Eastern-European Journal of Enterprise Technologies, 4 (6 (112)), 33–40. doi: https://doi.org/10.15587/1729-4061.2021.236977

- Liu, D., Gong, C., Tang, Y., Jian, Y., Cao, K., Chen, H. (2022). Evaluation of Corrosion Damage in Sulfate-Attacked Concrete by CT, Ultrasonic Pulse Velocity Testing and AHP Methods. Sensors, 22 (8), 3037. doi: https://doi.org/10.3390/s22083037

- Ariza-Figueroa, H. A., Bosch, J., Baltazar-Zamora, M. A., Croche, R., Santiago-Hurtado, G., Landa-Ruiz, L. et al. (2020). Corrosion Behavior of AISI 304 Stainless Steel Reinforcements in SCBA-SF Ternary Ecological Concrete Exposed to MgSO4. Materials, 13 (10), 2412. doi: https://doi.org/10.3390/ma13102412

- Li, T., Huang, H.-H. (2021). Probabilistic quantitative analysis on the contents of sulfate corrosion products in concrete. Construction and Building Materials, 275, 122134. doi: https://doi.org/10.1016/j.conbuildmat.2020.122134

- Murphy, C. J., Ardy Nugroho, F. A., Härelind, H., Hellberg, L., Langhammer, C. (2020). Plasmonic Temperature-Programmed Desorption. Nano Letters, 21 (1), 353–359. doi: https://doi.org/10.1021/acs.nanolett.0c03733

- Bozhokin, M. S., Bozhkova, S. A., Rubel, A. A., Sopova, J. V., Nashchekina, Y. A., Bildyug, N. B., Khotin, M. G. (2021). Specificities of Scanning Electron Microscopy and Histological Methods in Assessing Cell-Engineered Construct Effectiveness for the Recovery of Hyaline Cartilage. Methods and Protocols, 4 (4), 77. doi: https://doi.org/10.3390/mps4040077

- Calvin, J. J., Kaufman, T. M., Sedlak, A. B., Crook, M. F., Alivisatos, A. P. (2021). Observation of ordered organic capping ligands on semiconducting quantum dots via powder X-ray diffraction. Nature Communications, 12 (1). doi: https://doi.org/10.1038/s41467-021-22947-x

- Shkromada, O., Fotina, T., Dudnyk, Y., Petrov, R., Levytska, V., Chivanov, V. et al. (2022). Reducing the biogenic corrosion of concrete in a pigsty by using disinfectants. Eastern-European Journal of Enterprise Technologies, 4 (6 (118)), 57–66. doi: https://doi.org/10.15587/1729-4061.2022.263310

- Shkromada, O., Pikhtirova, A., Chivanov, V., Ivchenko, V., Sribniak, N., Shvets, O., Litsman, Y. (2022). Detection of the synergetic influence of chemical and microbiological factors on the properties of concrete constructions at chemical plants during the long-term service. EUREKA: Physics and Engineering, 4, 114–126. doi: https://doi.org/10.21303/2461-4262.2022.002485

- Tan, Y., Yu, H., Ma, H., Zhang, Y., Wu, C. (2017). Study on the micro-crack evolution of concrete subjected to stress corrosion and magnesium sulfate. Construction and Building Materials, 141, 453–460. doi: https://doi.org/10.1016/j.conbuildmat.2017.02.127

- Gu, Y., Martin, R.-P., Omikrine Metalssi, O., Fen-Chong, T., Dangla, P. (2019). Pore size analyses of cement paste exposed to external sulfate attack and delayed ettringite formation. Cement and Concrete Research, 123, 105766. doi: https://doi.org/10.1016/j.cemconres.2019.05.011

- Zhao, W., Fan, Z., Li, X., Kong, L., Zhang, L. (2022). Characterization and Comparison of Corrosion Layer Microstructure between Cement Mortar and Alkali-Activated Fly Ash/Slag Mortar Exposed to Sulfuric Acid and Acetic Acid. Materials, 15 (4), 1527. doi: https://doi.org/10.3390/ma15041527

- Zhao, G., Shi, M., Guo, M., Fan, H. (2020). Degradation Mechanism of Concrete Subjected to External Sulfate Attack: Comparison of Different Curing Conditions. Materials, 13 (14), 3179. doi: https://doi.org/10.3390/ma13143179

- Li, J., Zhao, G., Shi, M. (2020). Degradation and life prediction model for piles due to crystallisation attack in sulfate saline area. Advances in Cement Research, 32 (4), 181–195. doi: https://doi.org/10.1680/jadcr.18.00147

- Zhao, G., Li, J., Han, F., Shi, M., Fan, H. (2019). Sulfate-induced degradation of cast-in-situ concrete influenced by magnesium. Construction and Building Materials, 199, 194–206. doi: https://doi.org/10.1016/j.conbuildmat.2018.12.022

- Shkromada, O., Ivchenko, V., Chivanov, V., Tsyhanenko, L., Tsyhanenko, H., Moskalenko, V. et al. (2021). Defining patterns in the influence exerted by the interelated biochemical corrosion on concrete building structures under the conditions of a chemical enterprise. Eastern-European Journal of Enterprise Technologies, 2 (6 (110)), 52–60. doi: https://doi.org/10.15587/1729-4061.2021.226587

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Oksana Shkromada, Viktoriia Ivchenko, Vadym Chivanov, Olha Shvets, Volodymir Moskalenko, Alexander Kochenko, Olena Babenko, Yuliya Kharchenko, Alina Pikhtirova, Oksana Yurchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.