A time-frequency approach to ensuring stability of machining by turning

DOI:

https://doi.org/10.15587/1729-4061.2022.268637Keywords:

stability of the cutting process, stability lobes diagram, frequency stability criterion, machining by turningAbstract

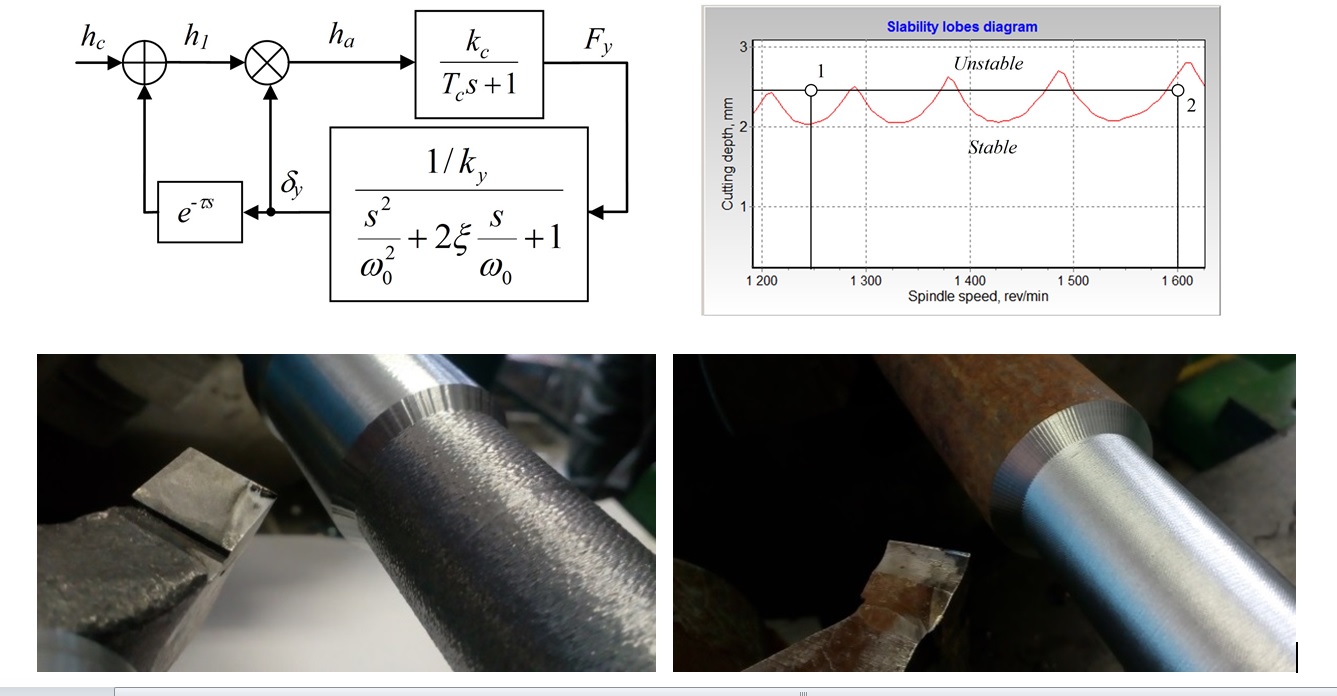

This paper reports a new approach to ensuring the stability of the turning process, which is based on the frequency-time characteristics of the technological machining system (TMS). The approach uses a mathematical model of the turning process as a single-mass system with one degree of freedom, taking into account negative feedback on the normal coordinate and positive feedback with a delay in cutting depth. A new criterion for the stability of the cutting process as a system with a delay in positive feedback is proposed, based on the analysis of frequency characteristics in the form of a Nyquist diagram. It is proved that such a system will be stable when the chart of its Nyquist diagram does not cover a point with coordinates [+1, 0] on the complex plane. The validity of the new criterion has been confirmed by comparing the simulation results in the time range with the location of the Nyquist diagram on the complex plane. Based on the new criterion of stability, an algorithm for automatic construction of a Stability Lobes Diagram (SLD) has been developed. The necessary a priori parameters of TMS, the ranges of frequency change, and the calculation step for constructing such a characteristic in the coordinates "cutting depth – spindle rotational speed" have been determined. The adequacy of the obtained results is confirmed by a full-scale experiment to assess the roughness of machined parts under cutting modes that fall into the area of stability and instability on the SLD chart. The full-scale experiment proved the possibility of a significant reduction in roughness according to the Rz parameter, from 43 µm to 18 µm, while increasing productivity by 1.28 times. The use of a stability lobes diagram is especially effective when programming CNC lathes where it is possible to select the spindle speed in a wide range.

References

- Kayhan, M., Budak, E. (2009). An experimental investigation of chatter effects on tool life. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 223 (11), 1455–1463. doi: https://doi.org/10.1243/09544054jem1506

- Quintana, G., Ciurana, J., Teixidor, D. (2008). A new experimental methodology for identification of stability lobes diagram in milling operations. International Journal of Machine Tools and Manufacture, 48 (15), 1637–1645. doi: https://doi.org/10.1016/j.ijmachtools.2008.07.006

- Tobias, S., Fishwick, W. (1958). Theory of Regenerative Machine Tool Chatter. The Engineer, 199–205. Available at: http://www.vibraction.fr/images/stories/Documents/1erePresentationLobesTobias.pdf

- Tlusty, J., Polacek, M. (1963). The Stability of Machine Tools against Self Excited Vibrations in Machining. International research in production engineering, ASME, 465–474. Available at: http://www.vibraction.fr/images/stories/Documents/2emePresentationLobesTlusty.pdf

- Budak, E., Altintas, Y. (1995). Modeling and avoidance of static form errors in peripheral milling of plates. International Journal of Machine Tools and Manufacture, 35 (3), 459–476. doi: https://doi.org/10.1016/0890-6955(94)p2628-s

- Altintas, Y., Weck, M. (2004). Chatter Stability of Metal Cutting and Grinding. CIRP Annals, 53 (2), 619–642. doi: https://doi.org/10.1016/s0007-8506(07)60032-8

- Quintana, G., Ciurana, J. (2011). Chatter in machining processes: A review. International Journal of Machine Tools and Manufacture, 51 (5), 363–376. doi: https://doi.org/10.1016/j.ijmachtools.2011.01.001

- Khasawneh, F. A. (2015). Stability Analysis of Machining Processes Using Spectral Element Approach. IFAC-PapersOnLine, 48 (12), 340–345. doi: https://doi.org/10.1016/j.ifacol.2015.09.401

- Yue, C., Gao, H., Liu, X., Liang, S. Y., Wang, L. (2019). A review of chatter vibration research in milling. Chinese Journal of Aeronautics, 32 (2), 215–242. doi: https://doi.org/10.1016/j.cja.2018.11.007

- Altintas, Y., Stepan, G., Budak, E., Schmitz, T., Kilic, Z. M. (2020). Chatter Stability of Machining Operations. Journal of Manufacturing Science and Engineering, 142 (11). doi: https://doi.org/10.1115/1.4047391

- Petrakov, Y. V. (2019). Chatter suppression technologies for metal cutting. Mechanics and Advanced Technologies, 86 (2). doi: https://doi.org/10.20535/2521-1943.2019.86.185849

- Altintas, Y., Ber, A. (2001). Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design. Applied Mechanics Reviews, 54 (5), B84–B84. doi: https://doi.org/10.1115/1.1399383

- Sipahi, R., Niculescu, S.-I., Abdallah, C.T., Michiels, W., Gu, K. (2011). Stability and Stabilization of Systems with Time Delay. IEEE Control Systems, 31 (1), 38–65. doi: https://doi.org/10.1109/mcs.2010.939135

- Petrakov, Y., Danylchenko, M., Petryshyn, A. (2019). Prediction of chatter stability in turning. Eastern-European Journal of Enterprise Technologies, 5 (1 (101)), 58–64. doi: https://doi.org/10.15587/1729-4061.2019.177291

- Szulewski, P., Śniegulska-Grądzka, D. (2017). Systems of automatic vibration monitoring in machine tools. Mechanik, 90 (3), 170–175. doi: https://doi.org/10.17814/mechanik.2017.3.37

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Yuri Petrakov, Mariia Danylchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.