Theoretical substantiation of the conditions for capture of fiber by the working drum by the knife in roller gins

DOI:

https://doi.org/10.15587/1729-4061.2022.269138Keywords:

drum surface, tightening force, knife-drum, flyer fiber, wedge gapAbstract

Roller ginning provides 2–3 times less mechanical damage to cotton fiber than saw ginning. In recent years, these positive moments have predetermined attempts to gin medium-fiber cotton on roller gins. However, the low productivity of roller gins compared to saw gins does not yet allow for a complete transition to this process.

To design high-efficiency roller gins, it is necessary to deeply study the mechanics of the basic processes of interaction of raw cotton with the working organs of the gin. It is necessary to determine the reserves for improving the efficiency of the process of capturing and tightening the fiber behind the knife, to investigate the mechanics of the process of rebounding seeds, and to find new solutions to reduce their damage.

As a result of the research reported here, a mathematical model of the roller ginning process has been built, which makes it possible to determine the impact of technological and structural parameters of the roller gin on the efficiency of the process. This allows for the reasonable application of a variable periodic friction field between the knife and working drum.

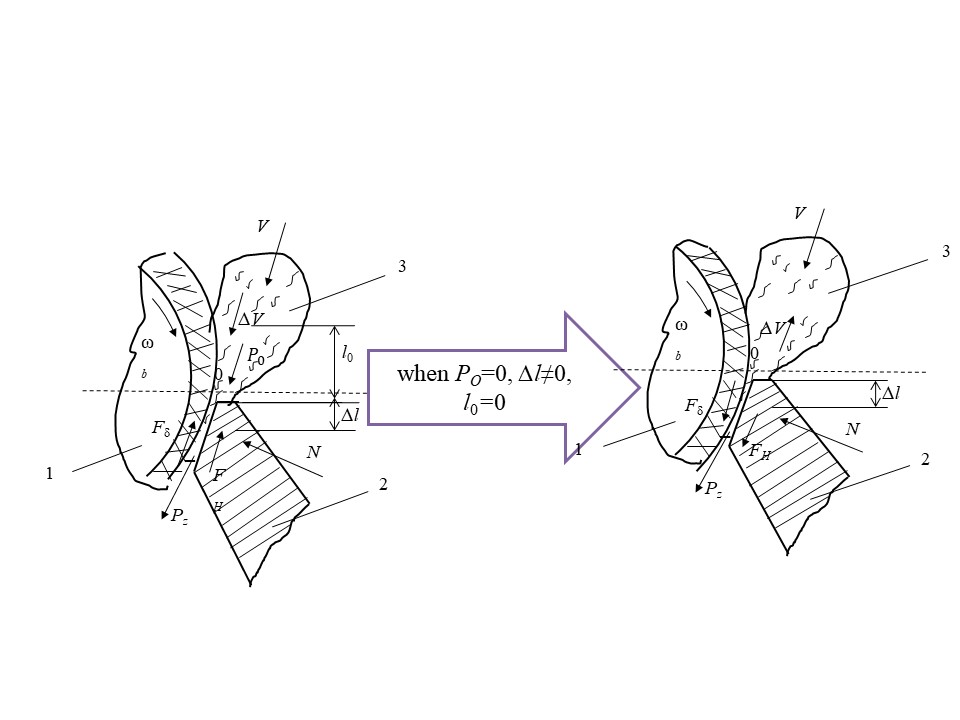

When studying the kinematics of the interaction of the surface of the working drum with the knife, dependences were established to accelerate the points of the surface of the working drum before it enters behind the knife, making it possible to determine the forces acting on the fiber when it is captured by the micro-irregularities of the drum.

In the study of the process of tightening the fiber with a pair of working drum-fixed knife, the conditions for ginning the flyer fibers and the dependence of productivity on the average pressure in the contact of the knife with the drum were determined. The study of the influence of the rigid characteristics of the working drum-knife system on the ginning capacity of a roller gin has made it possible to reveal new reserves for improving the efficiency of roller ginning

References

- Khafizov, I. K. (2007). Novyi material rabochego valika. Khlopkovaia promyshlennost, 4, 15–16.

- Khakimov, S., Makxammadiyev, Z., Khadjayeva, M. (2022). Study of durability of the clear grooves of the working drum of the roller jin. Universum: Technical Sciences, 3 (96). doi: https://doi.org/10.32743/unitech.2022.96.3.13300

- Safarov, F. M., Korabelnikov, R. V. (2006). Optimizatciia rezhimov dzhinirovaniia novogo selektcionnogo sorta dlinnovoloknistogo khlopka 9326-V. Izvestiia Vuzov. Tekhnologiia tekstilnoi promyshlennosti, 5 (293), 49–51. Available at: https://ttp.ivgpu.com/wp-content/uploads/2015/12/293_13.pdf

- Bavabekov, I. T. (1981). Vybor skorosti otboinogo organa valichnogo dzhina. Khlopkovaia promyshlennost, 2, 18–20.

- Ibrogimov, Kh. I. Korabelnikov, R. V. (2009). Parametry dvizheniia chastitc khlopka-syrtca po poverkhnosti kolkov v ochistiteliakh melkogo sora. Izvestiia Vuzov. Tekhnologiia tekstilnoi promyshlennosti, 1 (313), 34–36. Available at: https://ttp.ivgpu.com/wp-content/uploads/2015/11/313_10.pdf

- Akramov, A. (1982). Vliianie uliuchnoi kanavki na kachestvo volokna i semian pri valichnom dzhinirovanii. Khlopkovaia promyshlennost, 3, 4–5.

- Umarzhonov, A. A. (1991). Issledovanie valichnogo dzhina s ochistitelem volokna individualnogo tipa. Khlopkovaia promyshlennost, 3, 14–15.

- Novikov, E. V., Korabelnikov, R. V. (2004). Razrabotka modeli prognozirovaniia izmeneniia massovoi doli kostry v protcesse trepaniia dlinnogo volokna. Izvestiia Vuzov. Tekhnologiia tekstilnoi promyshlennosti, 6, 32–35.

- Miroshnichenko, G. I. (1972). Osnovy proektirovaniia mashin pervichnoi obrabotki khlopka. Moscow: Mashinostroenie, 486.

- Armijo, C. B., Whitelock, D. P., Thomas, J. W., Hughs, S. E., Gillum, M. N. (2017). Engineering and Ginning Roller Ginning. Journal of Cotton Science, 21 (3), 199–209. doi: https://doi.org/10.56454/vmim5000

- Korabelnikov, R. V., Ibrogimov, Kh. I. (2009). Osnovy protcessa zazhguchivaniia voloknistykh sviazei chastitc khlopka-syrtca pri netcentralnom udare kolkov. Izvestiia VUZov. Tekhnologiia tekstilnoi promyshlennosti, 4 (318), 23–28. Available at: https://ttp.ivgpu.com/wp-content/uploads/2015/11/318_6.pdf

- Zulfanov, S. Z., Safarov, F. M., Rudovskii, P. N. (2014). Vliianiia fiziko-mekhanicheskikh svoistv khlopka i tekhnologiia ego pererabotki na proizvoditelnost valichnogo dzhina. Vestnik Tadzhikskogo tekhnicheskogo universiteta im. akad. M. S. Osimi, 2 (26), 16–19. Available at: https://e.lanbook.com/journal/issue/294066

- Tursunov, Kh. K. (1990). Issledovanie vliianiia proizvoditelnosti valichnykh dzhinov na produkty pererabotki semennogo tonkovoloknistogo khlopka selektcii T-14. Khlopkovaia promyshlennost, 6, 16–19.

- Usmanov, D. A., Umarova, M. O. (2022) The process of cotton raw fine-fiber ginning. Universum: Technical Sciences, 4 (97). Availale at: https://7universum.com/ru/tech/archive/item/13494

- Kudratov, O. O. (1992). Issledovaniia zhestkosti sistemy rabochego valika nepodvizhnogo nozha valichnogo dzhina i ee vliianie na nadezhnost protcessa. Khlopkovaia promyshlennost, 3, 14–15.

- Miroshnichenko, G. I., Korabelnikov, R. V., Iakubov, D. Ia. (1992). Issledovanie plotnosti rabochego valika valichnogo dzhina i ee vliianiia na usilie zatiagivaniia za nozh. Khlopkovaia promyshlennost, 2, 7–8.

- Turakhonov, Kh. Kh. (1991). Issledovanie vliianiia konstruktivnykh parametrov otboinogo organa na tekhnologicheskie pokazateli raboty valichnogo dzhina. Khlopkovaia promyshlennost, 3, 14–15.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Fazil Veliev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.