Revealing the influence of structural and operational parameters of a wooden hydrostatic bearing on its performance

DOI:

https://doi.org/10.15587/1729-4061.2022.269703Keywords:

wooden bearing, specific pressure, thermal regime, bearing capacity, operational parametersAbstract

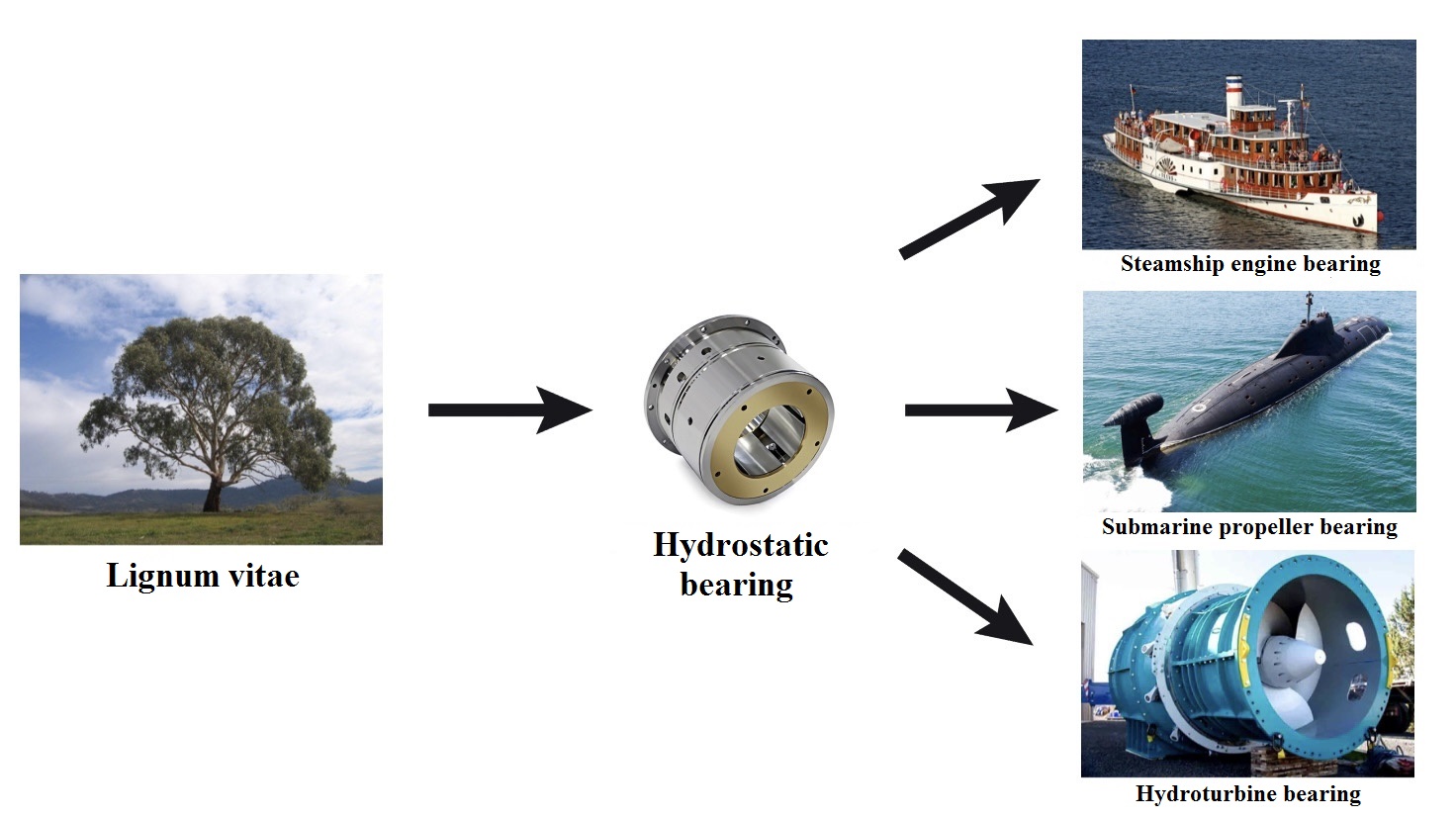

Wooden bearings, lubricated with water and other low-viscosity lubricants, have been used for centuries. In steamship engines, turbines of hydroelectric power plants and propellers of submarines, it is proposed to use wooden hydrostatic bearings, which are guaranteed to provide liquid friction and have high reliability.

The object of this study is hydrostatic and thermal processes in sliding supports with wooden hydrostatic bearings. The influence of the design and operational parameters of a wooden hydrostatic bearing on its performance was tackled. Theoretical dependences are given, making it possible to determine the bearing capacity and temperature increase in the hydrostatic bearing. Quantitative values of specific pressures on the working surface of the bearing and an increase in the temperature of the working fluid due to friction and pumping losses were established.

It was found that the specific pressures of the liquid do not exceed the tensile strength of the bearing material. The reduction in load capacity due to an increase in the temperature of the working fluid was 10.95 %, owing to the small change in the temperature of the working fluid in hydrostatic bearings. The results of the study make it possible to establish the permissible boundaries for the purpose of the design and operational parameters of the hydrostatic bearing ensuring its operability.

For the effective use of hydrostatic wooden bearings at the listed facilities, it is necessary to have a system for supplying lubricant to the bearing under high pressure. The system should include filters to clean the lubricant from impurities. The theoretical dependences built allow designers of hydrostatic bearings to use them in practical calculations

References

- Chandra, P. N., Reddy, P. P. S., Vinayak, K., Shukla, S. R., Rao, A. K. P. (2022). Wear of Wooden Journal Bearings. Biotribology, 29, 100205. doi: https://doi.org/10.1016/j.biotri.2021.100205

- Wetzk, V. (2006). Entwicklung der Brückenlager – Geschichtlicher Überblick. Bautechnik, 83 (10), 721–732. doi: https://doi.org/10.1002/bate.200610063

- Masaki, N., Takeuchi, S., Hirata, H. (2003). Dynamic Characteristics of a Sliding Bearing Using Lubricant Material for Base Isolation of Light Structures. Seismic Engineering. doi: https://doi.org/10.1115/pvp2003-2101

- Shamaev, V. A., Parinov, D. A., Polilov, A. N. (2018). Study of the Plain Bearings of Modified Wood for Heavy-Loaded Friction Assemblies. Journal of Machinery Manufacture and Reliability, 47 (2), 168–172. doi: https://doi.org/10.3103/s1052618818020115

- Anikeyeva, M. V., Vrublevskaya, V. I. (2020). Antifrictional Characteristics of Sliding Bearings from Modified Pressed Wood. Journal of Friction and Wear, 41 (5), 453–458. doi: https://doi.org/10.3103/s1068366620050025

- Tsubata, S., Sakai, S., Tanaka, S., Morita, T., Nishiya, T., Yamanobe, K., Kanayama, K. (2022). Influence of Thermal Softening of Wood on the Fundamental Performance of Drift Pin Joints I. Mokuzai Gakkaishi, 68 (1), 8–16. doi: https://doi.org/10.2488/jwrs.68.8

- Stoyanov, V. V., Zhgalli, S. (2016). Load Bearing Capacity of Wooden Bending Elements. Bulletin of Higher Educational Institutions. Lesnoi Zhurnal (Forestry Journal), 1, 115–121. doi: https://doi.org/10.17238/issn0536-1036.2016.1.115

- Sathre, R., Gorman, T. (2005). Improving the performance of wooden journal bearings. Forest Products Journal, 55 (11), 41–47. Available at: https://rogersathre.com/Sathre&Gorman_2005_wooden_bearings.pdf

- Dong, C., Yang, Y., Yuan, C., Bai, X., Guo, Z. (2022). Effects of anisotropy of lignum vitae wood on its tribological performances. Composites Part B: Engineering, 228, 109426. doi: https://doi.org/10.1016/j.compositesb.2021.109426

- Kim, S. S., Yu, H. N., Hwang, I. U., Lee, D. G. (2008). Characteristics of wood–polymer composite for journal bearing materials. Composite Structures, 86 (1-3), 279–284. doi: https://doi.org/10.1016/j.compstruct.2008.03.011

- Chi, K., Kang, J., Zhang, X., Xiao, S., Die, X. (2019). Experimental application of stochastic resonance based on Wood–Saxon potential on fault diagnosis of bearing and planetary gearbox. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 41 (11). doi: https://doi.org/10.1007/s40430-019-1999-x

- Wu, Z., Guo, Z., Yuan, C. (2022). Insight into the influence of the anatomical properties of wood on the tribological properties. Journal of Cleaner Production, 330, 129800. doi: https://doi.org/10.1016/j.jclepro.2021.129800

- Emtsev, B. T. (1978). Tekhnicheskaya gidromekhanika. Moscow: Mashinostroenie, 463.

- Uskov, M. S., Maksimov, V. A. (1985). Gidrodinamicheskaya teoriya smazki. Moscow: Nauka, 147.

- Tipey, N., Konstantinesku, V. N., Nika, A., Bitse, O. (1964). Podshipniki skol'zheniya (raschet, proektirovanie, smazka). Buharest, 457.

- Bogdanov, O. N., D'yachenko, S. K. (1966). Raschet opor skol'zheniya. Kyiv: Tekhnika, 242.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Vladimir Nazin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.