Determining patterns in the formation of a polymer shell by powder paint on wood surface

DOI:

https://doi.org/10.15587/1729-4061.2023.273364Keywords:

wood structure change, powder paints, thermal polymerization, pyrolysis and wood degassingAbstract

An issue related to using wood and wood products for building structures is to ensure their stability and durability during operation within wide limits. Therefore, the object of this study was a change in the properties of the polymer shell of powder paint on wood during thermal modification.

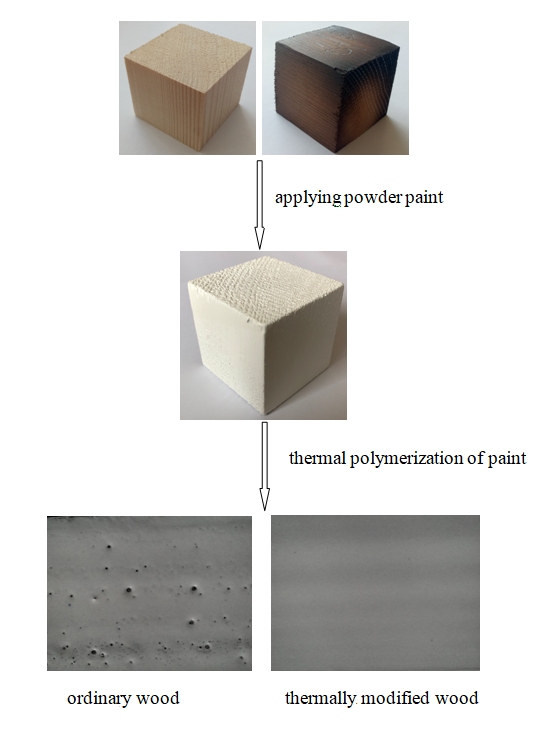

It is proved that in the process of thermal modification of wood, its structure changes, and accordingly, during the polymerization of powder paint, degassing occurs, which affects the polymer shell. Namely, during the thermal polymerization of powder paint at a temperature of 180 °C for untreated wood, shallow bubbles and craters are characteristic of the formed polymer shell. Instead, a smooth surface is marked for a sample of thermally modified wood. Thermogravimetric analysis data show thermogravimetric curves characterized by the loss of mass of the sample of the original wood with increasing temperature due to the processes of dehydration, destruction of hemicellulose and lignin. This is dehydration, accompanied by the destruction of the pyranose cycle, and carbonization to form a carbon residue and a complex mixture of volatile products. Due to this, bubbles and craters are formed in the polymer shell of the coating. Based on the obtained results of adhesion of the polymer shell on wood, which is treated with a mixture of epoxy polyester system with functional additives and a polymerization temperature of 180 °C, the adhesion level is 2.1 MPa. Reducing the polymerization temperature of a mixture of the epoxy polyester system with functional additives to 130 °C increases adhesion by 1.75 times, and the nature of the destruction passes through the polymer shell. For thermally modified wood, the level of adhesion is within 2.1 MPa, and the destruction takes place through the wood. This is due to the increased fragility of the surface after thermal modification of wood

References

- Ding, T., Yan, X., Zhao, W. (2022). Effect of Urea–Formaldehyde Resin–Coated Colour–Change Powder Microcapsules on Performance of Waterborne Coatings for Wood Surfaces. Coatings, 12 (9), 1289. doi: https://doi.org/10.3390/coatings12091289

- Ayrilmis, N. (2022). A review on electrostatic powder coatings for the furniture industry. International Journal of Adhesion and Adhesives, 113, 103062. doi: https://doi.org/10.1016/j.ijadhadh.2021.103062

- Akkus, M., Akbulut, T., Candan, Z. (2019). Application of electrostatic powder coating on wood composite panels using a cooling method. Part 1: Investigation of water intake, abrasion, scratch resistance, and adhesion strength. BioResources, 14 (4), 9557–9574. Available at: https://bioresources.cnr.ncsu.edu/resources/application-of-electrostatic-powder-coating-on-wood-composite-panels-using-a-cooling-method-part-1-investigation-of-water-intake-abrasion-scratch-resistance-and-adhesion-strength/

- Bai, J., Li, Y., Jiang, S., Guan, H. (2022). Preparation of wood furniture cooling coatings based on phase change microcapsules and its performance study. BioResources, 17 (1), 1319–1337. doi: https://doi.org/10.15376/biores.17.1.1319-1337

- Yan, X., Qian, X., Chang, Y., Lu, R., Miyakoshi, T. (2019). The Effect of Glass Fiber Powder on the Properties of Waterborne Coatings with Thermochromic Ink on a Chinese Fir Surface. Polymers, 11 (11), 1733. doi: https://doi.org/10.3390/polym11111733

- Yan, X., Wang, L., Qian, X. (2019). Influence of Thermochromic Pigment Powder on Properties of Waterborne Primer Film for Chinese Fir. Coatings, 9 (11), 742. doi: https://doi.org/10.3390/coatings9110742

- Hazir, E., Koc, K. H. (2019). Evaluation of wood surface coating performance using water based, solvent based and powder coating. Maderas. Ciencia y Tecnología, ahead, 21 (4). doi: https://doi.org/10.4067/s0718-221x2019005000404

- Cui, J., Li, W., Wang, Y., Yu, H., Feng, X., Lou, Z. et al. (2021). Ultra‐Stable Phase Change Coatings by Self‐Cross‐Linkable Reactive Poly(ethylene glycol) and MWCNTs. Advanced Functional Materials, 32 (10), 2108000. doi: https://doi.org/10.1002/adfm.202108000

- Ayrilmis, N., Akkuş, M., Yılmaz, S. N. (2021). Effect of thermal modification on the surface quality of a coating applied to wood via the electrostatic spray deposition technique. BioResources, 16 (4), 7355–7366. doi: https://doi.org/10.15376/biores.16.4.7355-7366

- Tsapko, Y., Horbachova, O., Mazurchuk, S., Bondarenko, O. P. (2022). Specific Aspects of the Study of the Surface Properties of Plywood. Materials Science Forum, 1066, 175–182. doi: https://doi.org/10.4028/p-b15jpx

- Ayrilmis, N. (2020). Surface properties of oriented strand board coated by electrostatic dry powder spray deposition technique. BioResources, 15 (1), 1521–1530. Available at: https://bioresources.cnr.ncsu.edu/resources/surface-properties-of-oriented-strand-board-coated-by-electrostatic-dry-powder-spray-deposition-technique/

- Köhler, R., Sauerbier, P., Ohms, G., Viöl, W., Militz, H. (2019). Wood Protection through Plasma Powder Deposition – An Alternative Coating Process. Forests, 10 (10), 898. doi: https://doi.org/10.3390/f10100898

- Wuzella, G., Kandelbauer, A., Mahendran, A. R., Müller, U., Teischinger, A. (2014). Influence of thermo-analytical and rheological properties of an epoxy powder coating resin on the quality of coatings on medium density fibreboards (MDF) using in-mould technology. Progress in Organic Coatings, 77 (10), 1539–1546. doi: https://doi.org/10.1016/j.porgcoat.2013.10.016

- Tsapko, Y., Horbachova, O., Tsapko, А., Mazurchuk, S., Zavialov, D., Buiskykh, N. (2021). Establishing regularities in the propagation of phase transformation front during timber thermal modification. Eastern-European Journal of Enterprise Technologies, 1 (10 (109)), 30–36. doi: https://doi.org/10.15587/1729-4061.2021.225310

- Tsapko, Y., Sirko, Z., Vasylyshyn, R., Melnyk, O., Tsapko, А., Bondarenko, O., Karpuk, A. (2021). Establishing patterns of mass transfer under the action of water on the hydrophobic coating of the fire-retardant element of a tent. Eastern-European Journal of Enterprise Technologies, 4 (10 (112)), 45–51. doi: https://doi.org/10.15587/1729-4061.2021.237884

- D4541-22 - Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers. Available at: https://www.en-standard.eu/astm-d4541-22-standard-test-method-for-pull-off-strength-of-coatings-using-portable-adhesion-testers/?gclid=EAIaIQobChMIyOjNk7v0_AIVzwN7Ch2tuw9xEAAYAiAAEgKBAvD_BwE

- Broido, A. (1969). A simple, sensitive graphical method of treating thermogravimetric analysis data. Journal of Polymer Science Part A-2: Polymer Physics, 7 (10), 1761–1773. doi: https://doi.org/10.1002/pol.1969.160071012

- Tsapko, Y., Bondarenko, O., Horbachova, O., Mazurchuk, S., Buyskikh, N. (2021). Research activation energy in thermal modification of wood. E3S Web of Conferences, 280, 07009. doi: https://doi.org/10.1051/e3sconf/202128007009

- Tsapko, Y., Buiskykh, N., Likhnyovskyi, R., Horbachova, O., Tsapko, А., Mazurchuk, S. et al. (2022). Establishing regularities in the application of dry pine wood. Eastern-European Journal of Enterprise Technologies, 4 (10 (118)), 51–59. doi: https://doi.org/10.15587/1729-4061.2022.262203

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yuriy Tsapko, Ruslan Likhnyovskyi, Nataliia Buiskykh, Oleksandra Horbachova, Serhii Mazurchuk, Oles Lastivka, Аleksii Tsapko, Kostiantyn Sokolenko, Andrii Matviichuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.