Devising an approach to assessing the durability of bus body on a frame chassis

DOI:

https://doi.org/10.15587/1729-4061.2023.275656Keywords:

bus body durability, frame chassis, simulation, body corrosion, fatigue destructionAbstract

The object of this study is the processes and permissible limits of aging of bus bodies on the frame chassis during operation.

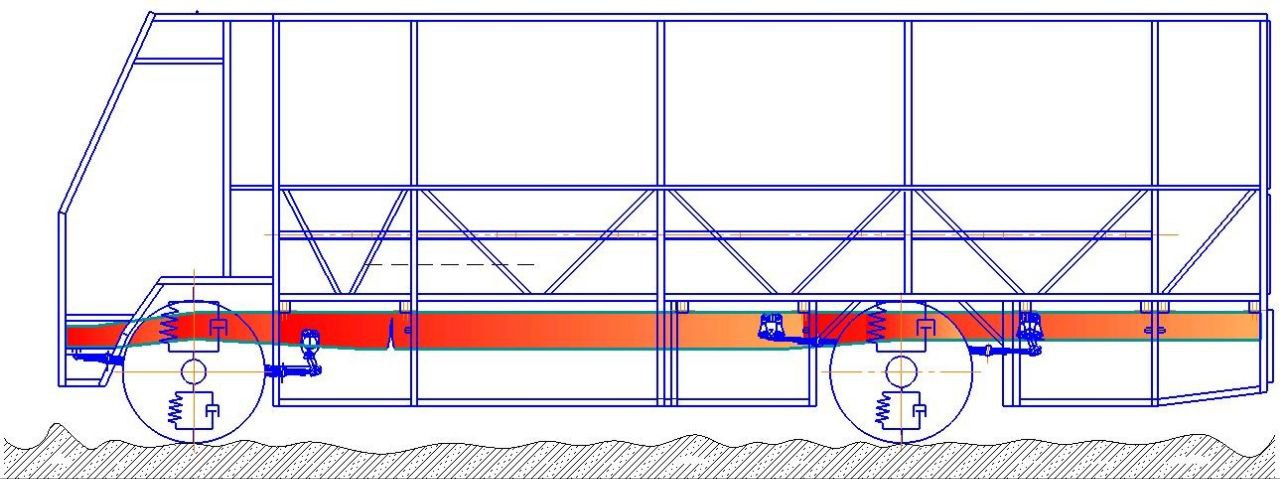

As a result of research by simulation method, the durability of the bus on the frame chassis, was determined, which is in the range from 5 to 11 years depending on the operating conditions. The study took into account the following factors: passenger occupancy, microprofile of the road, bus speed, corrosion. The durability of the bus depends primarily on the durability of the frame and body frame. Since the frame is made of alloy steels and heat-treated, it is not repaired but replaced with a new one when cracks in the frame are formed.

When determining the durability of the bus on the frame chassis, it was found that the frame has 1.5–1.8 times greater durability than the body frame itself. This is because the frame is made of alloyed materials and has an open structure. The body frame has closed cavities, which provoke the development of corrosion with the accumulation of moisture in them.

A feature of the results is that previous studies considered buses only with a load-bearing body structure.

The issue of durability of bodies on the frame chassis has been considered. As experience shows, the durability of bus bodies on a frame chassis depends on many operational factors. For operating organizations and manufacturing plants, it is important to provide for the durability of the bus depending on the operating conditions.

The results of this study will allow operating organizations to provide for scheduled repairs, as well as take measures to increase the service life of buses during operation. For manufacturing plants, the findings will make it possible to apply rational technologies and materials to form the service life of the bus body.

References

- Ruban, D., Kraynyk, L., Ruban, H., Sosyk, A., Shcherbyna, A., Dudarenko, O., Artyukh, A. (2021). Forecasting the durability of public transport bus bodies depending on operating conditions. Eastern-European Journal of Enterprise Technologies, 4 (1 (112)), 26–33. doi: https://doi.org/10.15587/1729-4061.2021.238171

- MathWorks. Available at: https://www.matlab.com/

- Ruban, D., Kraynyk, L., Ruban, H., Hrubel, M., Duzhyi, R., Babaryha, A. (2022). Development of technological principles of technical control of bus bodies during operation based on passive safety conditions. Eastern-European Journal of Enterprise Technologies, 6 (1 (120)), 91–100. doi: https://doi.org/10.15587/1729-4061.2022.268178

- Regulation No 66 of the Economic Commission for Europe of the United Nations (UN/ECE) – Uniform provisions concerning the approval of large passenger vehicles with regard to the strength of their superstructure. Available at: http://data.europa.eu/eli/reg/2011/66(2)/oj

- Farahani, B. V., Ramos, N. V., Moreira, P. M. G. P., Cunha, R., Costa, A., Maia, R., Rodrigues, R. M. (2022). Passive Safety Solutions on Transit Buses: Experimental and Numerical Analyses. Procedia Structural Integrity, 37, 668–675. doi: https://doi.org/10.1016/j.prostr.2022.01.136

- Boutar, Y., Naïmi, S., Mezlini, S., Carbas, R. J. C., da Silva, L. F. M., Ali, M. B. S. (2021). Cyclic fatigue testing: Assessment of polyurethane adhesive joints’ durability for bus structures’ aluminium assembly. Journal of Advanced Joining Processes, 3, 100053. doi: https://doi.org/10.1016/j.jajp.2021.100053

- Kepka, M., Kepka, M., Václavík, J., Chvojan, J. (2019). Fatigue life of a bus structure in normal operation and in accelerated testing on special tracks. Procedia Structural Integrity, 17, 44–50. doi: https://doi.org/10.1016/j.prostr.2019.08.007

- Kepka, M., Kepka, M., Dzugan, J., Konopik, P. (2019). Practical notes for assessing the fatigue life of bodyworks of buses and trolleybuses. Procedia Structural Integrity, 19, 595–603. doi: https://doi.org/10.1016/j.prostr.2019.12.064

- Kepka, M., Kepka, M. (2020). Accelerated fatigue testing on special tracks as new part of methodology for bus/trolleybus development. Engineering Failure Analysis, 118, 104786. doi: https://doi.org/10.1016/j.engfailanal.2020.104786

- Ruban, D. P. (2020). Mathematical Model of Forecasting Durability of Bus Bodies and Checking it for Adequacy. Visnyk of Vinnytsia Politechnical Institute, 150 (3), 81–89. doi: https://doi.org/10.31649/1997-9266-2020-150-3-81-89

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Dmytro Ruban, Lubomyr Kraynyk, Hanna Ruban, Maria Zakharova, Volodymyr Metelap, Vladyslav Khotunov, Sergiy Mykhaylyuta

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.