Applying multi-criteria decision-making methods for cutting oil selection

DOI:

https://doi.org/10.15587/1729-4061.2023.275717Keywords:

cutting oil, MCDM methods, CURLI method, PIV method, weight methodAbstract

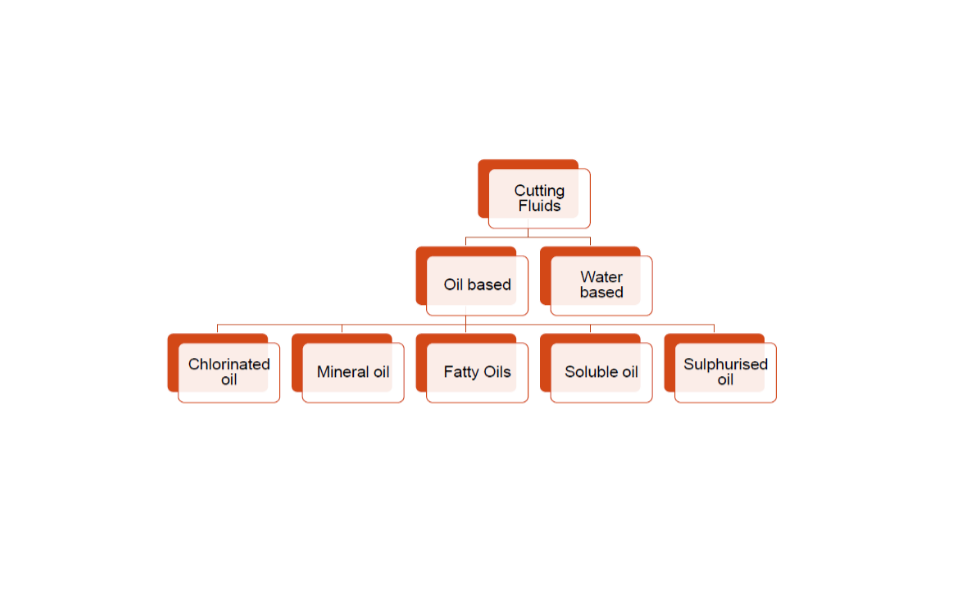

Many machining processes would not be possible without the presence of cutting oils. There are many different types of cutting oils on the market today, each with different properties. The difference of oils is manifested in many parameters such as viscosity, combustion temperature, recyclability, pollution tendency, stability, price, etc. Choosing the best oil is a difficult and tedious task for customers. In this work, we present the results of a study on the selection of cutting oil using multicriteria decisionmaking (MCDM) methods. The selection of the best oil is made on the basis of ranking of seven different types. Two MCDM methods used in this study are Proximity Indexed Value (PIV) and Collaborative Unbiased Rank List Integration (CURLI). This two methods have been used to rank cutting oils. These are two methods with completely different characteristics. When using the PIV method, it is necessary to standardize the data and determine the weights for the criteria. Meanwhile, if using the CURLI method, these two tasks are not needed. In addition, three different weight methods were also used to calculate the weights for the criteria including EQUAL, Rank Order Centroid weight (ROC weight) and Rank Sum weight (RS weight). These three methods have been used to determine the weights for the criteria of cutting oil. The PIV method was used three times corresponding to three different weight methods. The results showed that out of the four ranking results (three using the PIV method and one using the CURLI method), the same best oil was unanimously identified. It is recommended that the CURLI method should be used if weighting of criteria and data normalization are not desired

References

- Nguyen, H. S., Vo, N. U. T. (2022). Multi-Objective Optimization in Turning Process Using RIM Method. Applied Engineering Letters : Journal of Engineering and Applied Sciences, 7 (4), 143–153. doi: https://doi.org/10.18485/aeletters.2022.7.4.2

- Petković, D., Madić, M., Radovanović, M., Gečevska, V. (2017). Application of the performance selection index method for solving machining mcdm problems. Facta Universitatis, Series: Mechanical Engineering, 15 (1), 97. doi: https://doi.org/10.22190/fume151120001p

- Madić, M., Radovanović, M., Manić, M. (2016). Application of the ROV method for the selection of cutting fluids. Decision Science Letters, 245–254. doi: https://doi.org/10.5267/j.dsl.2015.12.001

- Jagadish, Ray, A. (2014). Cutting Fluid Selection for Sustainable Design for Manufacturing: An Integrated Theory. Procedia Materials Science, 6, 450–459. doi: https://doi.org/10.1016/j.mspro.2014.07.058

- Sen, B., Gupta, M., Mia, M., Pimenov, D., Mikołajczyk, T. (2021). Performance Assessment of Minimum Quantity Castor-Palm Oil Mixtures in Hard-Milling Operation. Materials, 14 (1), 198. doi: https://doi.org/10.3390/ma14010198

- Deshamukhya, T., Ray, A. (2014). Selection of cutting fluid for greenmanufacturing using Analytical Hierarchy Process (AHP): A CASE STUDY. International Journal of Mechanical Engineering and Robotics Research, 3 (1), 173–182. Available at: http://www.ijmerr.com/v3n1/ijmerr_v3n1_20.pdf

- Goswami, S. S., Behera, D. K. (2021). Implementation of COPRAS and ARAS MCDM Approach for the Proper Selection of Green Cutting Fluid. Current Advances in Mechanical Engineering, 975–987. doi: https://doi.org/10.1007/978-981-33-4795-3_90

- Jayant, A., Neeru, Singh, P. (2018). A decision-making framework model of cutting fluid selection for green manufacturing: A synthesis of 3 MCDM approaches, 2018, 1st International Conference on Advances in Engineering and Technology. Quetta. Available at: https://www.researchgate.net/publication/323748301_A_DECISION-MAKING_FRAMEWORK_MODEL_OF_CUTTING_FLUID_SELECTION_FOR_GREEN_MANUFACTURING_A_SYNTHESIS_OF_3_MCDM_APPROACHES

- Jagadish, Ray, A. (2014). Green cutting fluid selection using moosra method. International Journal of Research in Engineering and Technology, 03 (03), 559–563. doi: https://doi.org/10.15623/ijret.2014.0315105

- Duc Trung, D. (2021). A combination method for multi-criteria decision making problem in turning process. Manufacturing Review, 8, 26. doi: https://doi.org/10.1051/mfreview/2021024

- Trung, D. D. (2021). Application of EDAS, MARCOS, TOPSIS, MOORA and PIV Methods for Multi-Criteria Decision Making in Milling Process. Strojnícky Časopis - Journal of Mechanical Engineering, 71 (2), 69–84. doi: https://doi.org/10.2478/scjme-2021-0019

- Do, T. (2021). The Combination of Taguchi – Entropy – WASPAS - PIV Methods for Multi-Criteria Decision Making when External Cylindrical Grinding of 65G Steel. Journal of Machine Engineering, 21 (4), 90–105. doi: https://doi.org/10.36897/jme/144260

- Do, T. (2021). Application of TOPSIS an PIV Methods for Multi - Criteria Decision Making in Hard Turning Process. Journal of Machine Engineering, 21 (4), 57–71. doi: https://doi.org/10.36897/jme/142599

- Trung, D. D. (2022). Comparison R and CURLI methods for multi-criteria decision making. Advanced Engineering Letters, 1 (2), 46–56. doi: https://doi.org/10.46793/adeletters.2022.1.2.3

- Tran, D. V. (2022). Application of the Collaborative Unbiased Rank List Integration Method to Select the Materials. Applied Engineering Letters : Journal of Engineering and Applied Sciences, 7 (4), 133–142. doi: https://doi.org/10.18485/aeletters.2022.7.4.1

- Dua, T. V. (2023). Combination of symmetry point of criterion, compromise ranking of alternatives from distance to ideal solution and collaborative unbiased rank list integration methods for woodworking machinery selection for small business in Vietnam. EUREKA: Physics and Engineering, 2, 83–96. doi: https://doi.org/10.21303/2461-4262.2023.002763

- Nguyen, A.-T. (2023). The Improved CURLI Method for Multi-Criteria Decision Making. Engineering, Technology & Applied Science Research, 13 (1), 10121–10127. doi: https://doi.org/10.48084/etasr.5538

- Dung, H. T., Do, D. T., Nguyen, V. T. (2022). Comparison of Multi-Criteria Decision Making Methods Using The Same Data Standardization Method. Strojnícky Časopis - Journal of Mechanical Engineering, 72 (2), 57–72. doi: https://doi.org/10.2478/scjme-2022-0016

- Son, N. H., Hieu, T. T. (2023). Selection of welding robot by multi-criteria decision-making method. Eastern-European Journal of Enterprise Technologies, 1 (3 (121)), 66–72. doi: https://doi.org/10.15587/1729-4061.2023.269026

- Mufazzal, S., Muzakkir, S. M. (2018). A new multi-criterion decision making (MCDM) method based on proximity indexed value for minimizing rank reversals. Computers & Industrial Engineering, 119, 427–438. doi: https://doi.org/10.1016/j.cie.2018.03.045

- Kiger, J. R., Annibale, D. J. (2016). A new method for group decision making and its application in medical trainee selection. Medical Education, 50 (10), 1045–1053. doi: https://doi.org/10.1111/medu.13112

- Trung, D. D. (2022). Development of data normalization methods for multi-criteria decision making: applying for MARCOS method. Manufacturing Review, 9, 22. doi: https://doi.org/10.1051/mfreview/2022019

- Podvezko, V. (2009). Application of AHP Technique. Journal of Business Economics and Management, 10 (2), 181–189. doi: https://doi.org/10.3846/1611-1699.2009.10.181-189

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Hoang Xuan Thinh, Nguyen Trong Mai, Nguyen Truong Giang, Vu Van Khiem

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.