Research of process water of a thermal power plant

DOI:

https://doi.org/10.15587/1729-4061.2023.276486Keywords:

thermal power plant, flow rate, pressure, temperature, scale, reagents, coagulants, elements, filtration, cleaning, washingAbstract

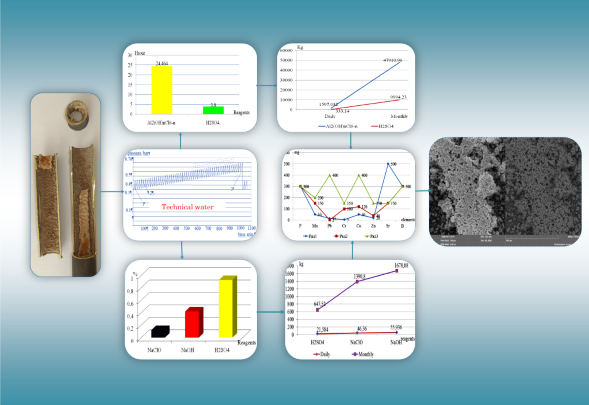

The article is devoted to the study of technical water used in thermal power plants. One of the devices of thermoelectric plant are heat exchangers, heat exchangers consist of pipes of different diameters. Heat exchangers used in production plants are made of carbon steel, suitable for high temperatures (up to 565 °C). At the same time inside the heat exchangers used for a certain period of time, a scale is formed in the form of a solid sediment, which reduces the thermal efficiency of heat carriers. Therefore, in this paper, the object of research are the heat transfer fluids of industrial heat exchangers, namely feed and process water. In order to obtain feed water at industrial thermal power plants, special water treatment processes are carried out. That is, its main purpose is to prevent the formation of solid deposits in heat exchangers. The studied water samples were taken directly from the thermal power plant from different stages of water treatment, i. e. raw water entering the chemical shop, treated water entering the deaerator, feed water entering the boiler. As a result of the study, water samples related to the formation of scale on the surfaces of heat exchangers, i. e. dosed amounts, elemental composition and particles were studied. During the study, hourly, daily and monthly dosages of reagents were determined. In addition, the elemental compositions of raw water, pure water and feed water of the thermal power plant were investigated. The results of this study allow to explore ways of economical and effective descaling formed in heat exchangers

Supporting Agency

- This research is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant no. AP14870433).

References

- Shao, W., Feng, J., Liu, J., Yang, G., Yang, Z., Wang, J. (2017) Research on the Status of Water Conservation in the Thermal Power Industry in Energy Procedia, 105, 3068–3075. doi: https://doi.org/10.1016/j.egypro.2017.03.639

- Zaharia, C., Stanciulescu, D. (2020). Process water treatment in a thermal power plant: characteristics and sediment/sludge disposal. Environmental Engineering and Management Journal, 19 (2), 255–267. doi: https://doi.org/10.30638/eemj.2020.024

- Dhokai, C., Palkar, R. R., Jain, V. (2022). Water saving in thermal power plant by use of membrane filter in cooling tower treatment. AIMS Environmental Science, 9 (3), 298–308. doi: https://doi.org/10.3934/environsci.2022020

- Kil, J. (2019). Solid state electrolytes capable of preventing backflow in raw water management of thermal power plants and its own method of manufacturing pH combination electrode. AIP Conference Proceedings. doi: https://doi.org/10.1063/1.5118119

- Lindahl, M., Svensson, N., Svensson, B. H., Sundin, E. (2013). Industrial cleaning with Qlean Water – a case study of printed circuit boards. Journal of Cleaner Production, 47, 19–25. doi: https://doi.org/10.1016/j.jclepro.2013.01.032

- DeNooyer, T. A., Peschel, J. M., Zhang, Z., Stillwell, A. S. (2016). Integrating water resources and power generation: The energy–water nexus in Illinois. Applied Energy, 162, 363–371. doi: https://doi.org/10.1016/j.apenergy.2015.10.071

- Tsubakizaki, S., Wada, T., Tokumoto, T., Ichihara, T., Kido, H., Takahashi, S. (2013). Water Quality Control Technology for Thermal Power Plants (Current Situation and Future Prospects). Mitsubishi Heavy Industries Technical Review, 50 (3). Available at: https://www.mhi.co.jp/technology/review/pdf/e503/e503022.pdf

- Tekhnologicheskie resheniya proekta 09L129 «Ustanovka t.a. st. No. 5 Vodopodgotovka podpitki teploseti s predochistkoy» razrabotany dlya AO «Institut «KazNIPIEnergoprom» (2019). Karaganda, 187.

- Kishnevskiy, V. A., Chichenin, V. V. (2014). Study on chemical control indicators for circulating cooling systems water chemistry at power plants. Eastern-European Journal of Enterprise Technologies, 4 (8 (70)), 57–62. doi: https://doi.org/10.15587/1729-4061.2014.26312

- Rudkovskaya, E. V., Omelchuk, Yu. A., Gomelya, D. (2013). Evaluation of the effectiveness of a new inhibitor to protect water-circulation cooling systems from scale formation and corrosion. Eastern European Journal of Corporate Technologies, 2 (8 (62)), 45–48.

- Shaimerdenova, K. M., Aitpaeva, Z.K., Khassenov, A. K., Bulkairova, G. A. (20117). Structural changes in electrodes and their failure on electric pulse treatment of water. Eurasian Physical Technical Journal, 1 (27), 103–108.

- Ospanova, D. A., Kutum, B. B., Nusupbekov, B. R. (2022). Features of nutrient water purification in thermal power facilities. Actual Scientific Research In The Modern World. International Science Journal, 10 (90), 138–144.

- Nussupbekov, B. R., Sakipova, S. E., Ospanova, D. A., Kutum, B. B., Shaimerdenova, K. M., Bekturganov, Zh. S. (2022). Some technological aspects of cleaning pipes of heat exchangers from solid scale deposits. Bulletin of the Karaganda University. “Physics” Series, 108 (4), 106–114. doi: https://doi.org/10.31489/2022ph4/106-114

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Bayan Kutum, Didar Ospanova, Bekbolat Nussupbekov, Yerlan Oshanov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.