Development of risk-based inspection of 28-years-old subsea sales gas pipelines to support the energy demand

DOI:

https://doi.org/10.15587/1729-4061.2023.277256Keywords:

risk-based Inspection, sales gas pipelines, ILI, Risk of FailureAbstract

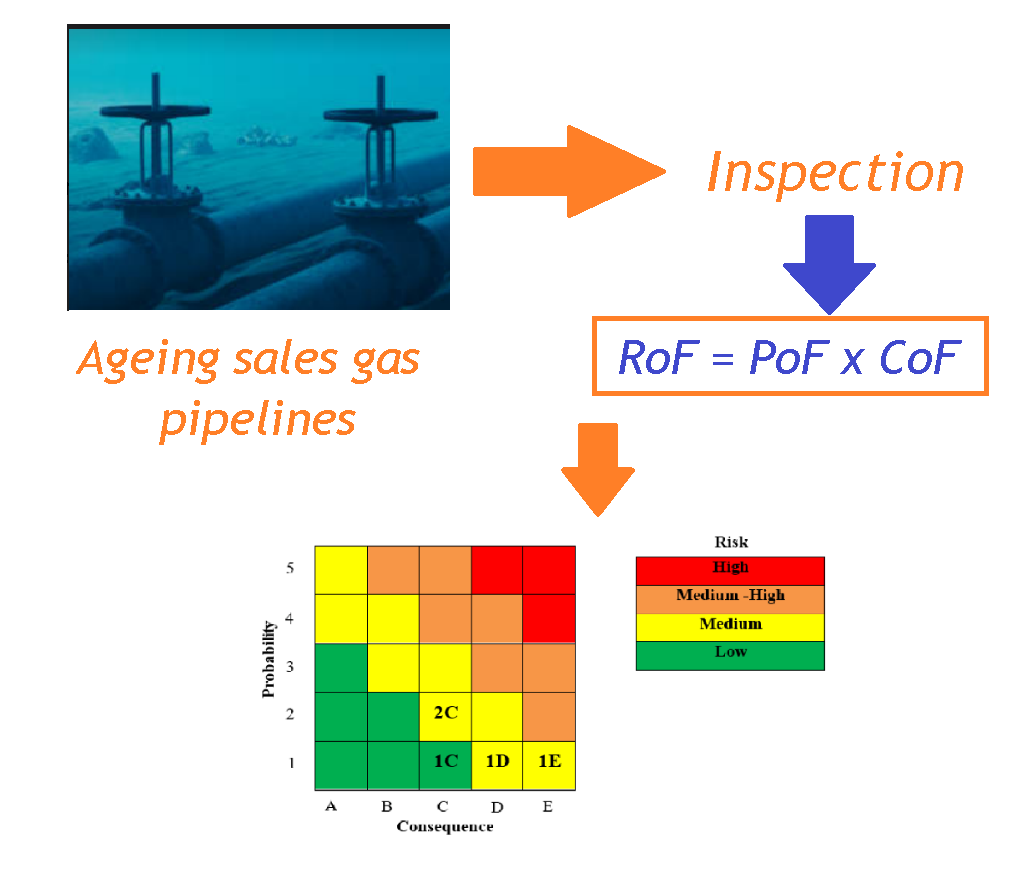

In the oil and gas industry, maintaining the integrity of production equipment is critical to ensuring the industry’s sustainability. Failure to maintain the integrity of production equipment can result in financial losses for the business. The management of production equipment nearing the end of its design life faces an increasing cost of Inspection, Maintenance, and Repair (IMR). As a result, a strategy to improve the efficiency of IMR is essential. Recent IMR management practices include predictive Risk-Based Inspection (RBI), which is more efficient than Time-Based Inspection (TBI). The research intends to evaluate the 28-year-old subsea sales gas pipeline using API 581 standard quantitative methodology by utilizing the Inline Inspection (ILI). Specifically, the study focuses on measuring the Probability and Consequence Failure of inspected pipelines. The inspection interval is determined based on the minimum allowable thickness. The risk calculation indicates that 12 pipeline segments are at a medium risk level (3 segments, 1D and 1E, and 2C). The remaining nine segments remain at lower risk (1C). Based on the result, segment nine is accepted as the highest PoF value of 1.04E-4 failures per year due to high depletion values due to the higher CoF value at the leak location. The calculation of the inspection interval indicates that the forthcoming Inspection will be due 20 years post the previous assessment. Another method using the Estimated Repair Factor (ERF) thickness limit approach produces the same results. However, assessment using ASME B31.8S provides different results of 10 years intervals when using the same ILI inspection method. This work can be used as a standard guideline to assess the risk of pipelines over a decade in service

References

- Adi, A. C. et al. (2018). 2018 Handbook Of Energy & Economic Statistics Of Indonesia. Minist. Energy Miner. Resour. Available at: https://www.esdm.go.id/assets/media/content/content-handbook-of-energy-and-economic-statistics-of-indonesia-2018.pdf

- Henao, F. A. (2021). Risk-based decisions: Implementing the asset integrity program. Process Safety Progress, 40 (S1). doi: https://doi.org/10.1002/prs.12287

- Aditiyawarman, T., Kaban, A. P. S., Soedarsono, J. W. (2022). A Recent Review of Risk-Based Inspection Development to Support Service Excellence in the Oil and Gas Industry: An Artificial Intelligence Perspective. ASCE-ASME J Risk and Uncert in Engrg Sys Part B Mech Engrg, 9 (1). doi: https://doi.org/10.1115/1.4054558

- Alfon, P., Soedarsono, J. W., Priadi, D., Sulistijono (2013). Application of Hoop Stress Limit State and Predicted Corrosion Rate in Underground Gas Transmission Pipeline Inspection Plan. Applied Mechanics and Materials, 328, 942–949. doi: https://doi.org/10.4028/www.scientific.net/amm.328.942

- Eckert, R. B. (2015). Are we learning from the past? Opportunities for continuous improvement of internal corrosion management programs.

- Aditiyawarman, T., Soedarsono, J. W., Kaban, A. P. S., Riastuti, R., Rahmadani, H. (2022). The Study of Artificial Intelligent in Risk-Based Inspection Assessment and Screening: A Study Case of Inline Inspection. ASCE-ASME J Risk and Uncert in Engrg Sys Part B Mech Engrg, 9 (1). doi: https://doi.org/10.1115/1.4054969

- Risk-Based Inspection Methodology (2016). American Petroleum Institutes (API).

- Seo, J. K., Cui, Y., Mohd, M. H., Ha, Y. C., Kim, B. J., Paik, J. K. (2015). A risk-based inspection planning method for corroded subsea pipelines. Ocean Engineering, 109, 539–552. doi: https://doi.org/10.1016/j.oceaneng.2015.07.066

- Ma, Q., Tian, G., Zeng, Y., Li, R., Song, H., Wang, Z. et al. (2021). Pipeline In-Line Inspection Method, Instrumentation and Data Management. Sensors, 21 (11), 3862. doi: https://doi.org/10.3390/s21113862

- Zhang, H., Zhang, S., Wang, Y., Liu, Y., Yang, Y., Zhou, T., Bian, H. (2021). Subsea pipeline leak inspection by autonomous underwater vehicle. Applied Ocean Research, 107, 102321. doi: https://doi.org/10.1016/j.apor.2020.102321

- Alfon, P., Soedarsono, J. W., Priadi, D., Sulistijono, S. (2011). Pipeline Material Reliability Analysis Regarding to Probability of Failure Using Corrosion Degradation Model. Advanced Materials Research, 422, 705–715. doi: https://doi.org/10.4028/www.scientific.net/amr.422.705

- Azmi, M. F., Soedarsono, J. W. (2018). Study of corrosion resistrance of pipeline API 5L X42 using green inhibitor bawang dayak (Eleutherine americanna Merr.) in 1M HCl. IOP Conference Series: Earth and Environmental Science, 105, 012061. doi: https://doi.org/10.1088/1755-1315/105/1/012061

- Paul Setiawan Kaban, A., Mayangsari, W., Syaiful Anwar, M., Maksum, A., Riastuti, R., Aditiyawarman, T., Wahyuadi Soedarsono, J. (2022). Experimental and modelling waste rice husk ash as a novel green corrosion inhibitor under acidic environment. Materials Today: Proceedings, 62, 4225–4234. doi: https://doi.org/10.1016/j.matpr.2022.04.738

- Kaban, A. P. S., Soedarsono, J. W., Mayangsari, W., Anwar, M. S., Maksum, A., Ridhova, A., Riastuti, R. (2023). Insight on Corrosion Prevention of C1018 in 1.0 M Hydrochloric Acid Using Liquid Smoke of Rice Husk Ash: Electrochemical, Surface Analysis, and Deep Learning Studies. Coatings, 13 (1), 136. doi: https://doi.org/10.3390/coatings13010136

- Ismail, W. M. M. W., Napiah, M. N. M. A., Zabidi, M. Z. M., Tuselim, A. S. M. (2020). Managing Risk: Effective Use of Structural Reliability Assessment (SRA) and Quantitative Risk Assessment (QRA) for Sabah-Sarawak Gas Pipeline (SSGP). Pipeline Integrity Management Under Geohazard Conditions (PIMG), 387–394. doi: https://doi.org/10.1115/1.861998_ch41

- Taha, W., Abou-Khousa, M., Haryono, A., AlShehhi, M., Al-Wahedi, K., Al-Durra, A. et al. (2020). Field demonstration of a microwave black powder detection device in gas transmission pipelines. Journal of Natural Gas Science and Engineering, 73, 103058. doi: https://doi.org/10.1016/j.jngse.2019.103058

- González-Arévalo, N. E., Velázquez, J. C., Díaz-Cruz, M., Cervantes-Tobón, A., Terán, G., Hernández-Sanchez, E., Capula-Colindres, S. (2021). Influence of aging steel on pipeline burst pressure prediction and its impact on failure probability estimation. Engineering Failure Analysis, 120, 104950. doi: https://doi.org/10.1016/j.engfailanal.2020.104950

- Zhang, P., Su, L., Qin, G., Kong, X., Peng, Y. (2019). Failure probability of corroded pipeline considering the correlation of random variables. Engineering Failure Analysis, 99, 34–45. doi: https://doi.org/10.1016/j.engfailanal.2019.02.002

- Ghavami, S. M., Borzooei, Z., Maleki, J. (2020). An effective approach for assessing risk of failure in urban sewer pipelines using a combination of GIS and AHP-DEA. Process Safety and Environmental Protection, 133, 275–285. doi: https://doi.org/10.1016/j.psep.2019.10.036

- Hou, P., Yi, X., Dong, H. (2020). A Spatial Statistic Based Risk Assessment Approach to Prioritize the Pipeline Inspection of the Pipeline Network. Energies, 13 (3), 685. doi: https://doi.org/10.3390/en13030685

- Hameed, H., Bai, Y., Ali, L. (2020). A risk-based inspection planning methodology for integrity management of subsea oil and gas pipelines. Ships and Offshore Structures, 1–13. doi: https://doi.org/10.1080/17445302.2020.1747751

- API RP 581 - Risk-based Inspection Methodology (2016). American Petroleum Institute, 652.

- Shi, Y., Zhang, C., Li, R., Cai, M., Jia, G. (2015). Theory and Application of Magnetic Flux Leakage Pipeline Detection. Sensors, 15 (12), 31036–31055. doi: https://doi.org/10.3390/s151229845

- Sabry, H. (2014). Effective Asset Integrity Management through an Effective Risk Based Inspection Program- ADGAS’ Experience. Day 3 Wed, November 12, 2014. doi: https://doi.org/10.2118/171959-ms

- Corroded Pipelines, DNV-RP-F101 (2010). DNV.

- ASME B31G-2009: manual for determining the remaining strength of corroded pipelines (2009). ASME.

- Dehghani, A., Bahlakeh, G., Ramezanzadeh, B. (2019). A detailed electrochemical/theoretical exploration of the aqueous Chinese gooseberry fruit shell extract as a green and cheap corrosion inhibitor for mild steel in acidic solution. Journal of Molecular Liquids, 282, 366–384. doi: https://doi.org/10.1016/j.molliq.2019.03.011

- BS 7910. Guide to methods for assessing the acceptability of flaws in metallic structures (2013). BSI Stand. Publ.

- API RP 581: Risk-based inspection technology (2008). American Petroleum Institute.

- Bhatia, K., Khan, F., Patel, H., Abbassi, R. (2019). Dynamic risk-based inspection methodology. Journal of Loss Prevention in the Process Industries, 62, 103974. doi: https://doi.org/10.1016/j.jlp.2019.103974

- Matthews, C. (2009). An Introduction to API 570. A Quick Guide to API 570 Certified Pipework Inspector Syllabus, 10–18. doi: https://doi.org/10.1533/9781845696849.1.10

- NACE MR0175/ISO 15156-1. Petroleum and natural gas industries – Materials for use in H2S-containing Environments in oil and gas production – Part 1: General principles for selection of cracking-resistant materials.

- Scott, R. A. A. (2001). Multi-Service Vessels for Deepwater Subsea Well Interventions. All Days. doi: https://doi.org/10.4043/12947-ms

- Leuvinadrie, L. P., Soedarsono, J. W. M. (2021). Pipe stress simulation and failure analysis of carbon steel flange spool in CO2 gas flow condition. AIP Conference Proceedings. doi: https://doi.org/10.1063/5.0070886

- Asfar, Mhd. I. Y., Soedarsono, J. W., Wijaya, A., Aditiyawarman, T., Soelistiyono, D., Ramadhan, R. (2021). Quantitative Risk-Based Inspection on Gas Riser Pipelines at Offshore Facilities. Teknomekanik, 4 (2), 78–84. doi: https://doi.org/10.24036/teknomekanik.v4i2.11172

- Yusniati, M. (2005). Analisis Spasial Suhu Permukaan Laut di Perairan Laut Jawa Pada Musim Timur dengan Menggunakan Data Digital Satelit Noaa 16-Avhrr. Bogor Institute of Technology.

- Hart, E. (2016). Corrosion inhibitors: Principles, mechanisms and applications. Nova Science Publishers, Inc., 173.

- Lelo, N. A., Stephan Heyns, P., Wannenburg, J. (2022). Development of an approach to incorporate proportional hazard modelling into a risk-based inspection methodology. Journal of Quality in Maintenance Engineering, 29 (1), 265–285. doi: https://doi.org/10.1108/jqme-04-2021-0030

- Márquez-Domínguez, S., Sørensen, J. D. (2012). Fatigue Reliability and Calibration of Fatigue Design Factors for Offshore Wind Turbines. Energies, 5 (6), 1816–1834. doi: https://doi.org/10.3390/en5061816

- El-Abbasy, M. (2013). Predicting offshore oil and gas pipelines condition. Qatar Foundation Annual Research Forum, 2013 (1). doi: https://doi.org/10.5339/qfarf.2013.eep-05

- Bhandari, J., Abbassi, R., Garaniya, V., Khan, F. (2015). Risk analysis of deepwater drilling operations using Bayesian network. Journal of Loss Prevention in the Process Industries, 38, 11–23. doi: https://doi.org/10.1016/j.jlp.2015.08.004

- Vasseghi, A., Haghshenas, E., Soroushian, A., Rakhshandeh, M. (2021). Failure analysis of a natural gas pipeline subjected to landslide. Engineering Failure Analysis, 119, 105009. doi: https://doi.org/10.1016/j.engfailanal.2020.105009

- Rachman, A., Zhang, T., Ratnayake, R. M. C. (2021). Applications of machine learning in pipeline integrity management: A state-of-the-art review. International Journal of Pressure Vessels and Piping, 193, 104471. doi: https://doi.org/10.1016/j.ijpvp.2021.104471

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Johny Soedarsono, Arie Wijaya, Taufik Aditiyawarman, Agus Kaban, Rini Riastuti, Rizal Tresna Ramdhani, Ayende

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.