Identifying of the mechanism formation of a natural nanocomposite in polymer composite materials

DOI:

https://doi.org/10.15587/1729-4061.2023.277587Keywords:

cluster model, natural nanocomposite, interfacial region, inter-component adhesion, loosely packed matrix, nanoclustersAbstract

The object of the study is the sealing elements of the packer.

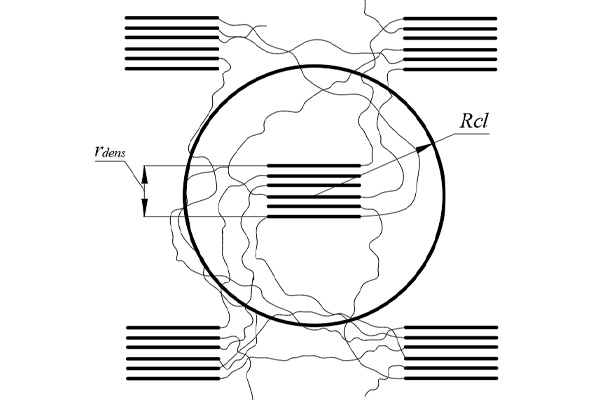

The fundamental principle of the cluster model is the assumption that the sum of the relative volume fractions of two structural elements of a natural nanocomposite (loosely packed matrix and nanoclusters) is equal to one – This approach is incorrect because it is violated when the nanoclusters are immersed in a loosely packed matrix. In this regard, a new relationship is proposed that relates the relative volume fractions of the loosely packed matrix and the part of nanoclusters immersed in it – Calculation formulas are obtained for the relative fractions of the loosely packed matrix and the interphase region.

The paper shows that such an assumption is unfounded due to the indispensable immersion of clusters in a loosely packed matrix, and in this regard, a new relationship is proposed linking the relative volume fractions of the loosely packed matrix and the part of nanoclusters immersed in it.

For a composite with a matrix, a mixture of synthetic butadiene nitrile and hydrogenated butadiene nitrile rubber and the addition of a copper nanoparticle, it is shown that in a natural nanocomposite, which is the polymer under study in an amorphous state, the time dependences of the relative volume fractions of the regions of inter-component adhesion and the loosely packed matrix coincide quite well with each other.

The application of the above relationship between the volume fractions of a loosely packed matrix and nanoclusters allows to reformulate the known equations of parallel and sequential micromechanical models, as well as the Kerner equation for a more complex micromechanical model used to describe the effect of strengthening the elastic modulus of nanocomposites

References

- Kopeikin, I. S. (2022). Development of a packer with an activation tool for the liner extension hanger in the interval of a horizontal open well. IOP Conference Series: Earth and Environmental Science, 981 (3), 032071. doi: https://doi.org/10.1088/1755-1315/981/3/032071

- Verisokin, A. E., Vasil’yev, V. A., Gun’kina, T. A. (2019). Packer design research used in hydraulic fracturing. IOP Conference Series: Earth and Environmental Science, 378 (1), 012106. doi: https://doi.org/10.1088/1755-1315/378/1/012106

- Suleymanova, A., Guseynova, V., Abasova, S. (2022). The choice of material for the manufacture of sealing elements of the packer. ETM - Equipment, Technologies, Materials, 09 (01), 43–47. doi: https://doi.org/10.36962/etm0901202243

- Dyshin, O. A., Habibov, I. A., Rustamova, K. B. (2018). Formation of the properties of the structure of disperse-filled polymer composites. PNRPU Mechanics Bulletin, 2, 24–31. doi: https://doi.org/10.15593/perm.mech/2018.2.03

- Dyshin, O. A., Habibov, I. A., Shamilov, V. M., Rustamova, K. B. (2019). The structure of interfacial regions in polymer nanocomposites. PNRPU Mechanics Bulletin, 3, 140–148. doi: https://doi.org/10.15593/perm.mech/2019.3.14

- Mammadova, M. (2022). Investigation of fluid dynamics in microfracture channels. Eastern-European Journal of Enterprise Technologies, 4 (7 (118)), 42–50. doi: https://doi.org/10.15587/1729-4061.2022.263480

- Babaev, S. G., Gabibov, I. A., Melikov, R. Kh. (2015). Osnovy teorii nadezhnosti neftepromyslovogo oborudovaniya. Baku, 400.

- Dolgikh, L. N. (2007). Kreplenie, ispytanie i osvoenie neftyanykh i gazovykh skvazhin. Perm', 189.

- Morozov, A. D., Popkov, D. O., Duplyakov, V. M., Mutalova, R. F., Osiptsov, A. A., Vainshtein, A. L. et al. (2020). Data-driven model for hydraulic fracturing design optimization: focus on building digital database and production forecast. Journal of Petroleum Science and Engineering, 194, 107504. doi: https://doi.org/10.1016/j.petrol.2020.107504

- Apasov, T. K., Apasov, G. T., Sarancha, A. V. (2015). Restoring the productivity of the wells after drilling and hydraulic fracturing by vibrowave method. Modern problems of science and education, 2 (2).

- Verisokin, A. E., Grab, A. N., Grab, D. N., Serikov, D. Yu. (2017). Faktory, vliyayuschie na rabotosposobnost' pakerov pri gidrorazryve plasta. Sfera Neft' i gaz, 4 (60), 26–30.

- Lan, W.-J., Wang, H.-X., Zhang, X., Chen, S.-S. (2019). Sealing properties and structure optimization of packer rubber under high pressure and high temperature. Petroleum Science, 16 (3), 632–644. doi: https://doi.org/10.1007/s12182-018-0296-0

- Hu, G., Zhang, P., Wang, G., Zhang, M., Li, M. (2017). The influence of rubber material on sealing performance of packing element in compression packer. Journal of Natural Gas Science and Engineering, 38, 120–138. doi: https://doi.org/10.1016/j.jngse.2016.12.027

- Mashkov, Yu. K., Kropotin, O. V., Shil'ko, S. V., Egorova, V. A., Chemisenko, O. V. (2016). Mekhanicheskie svoystva ptfe-nanokompozitov dlya uplotnitel'nykh elementov dinamicheskikh germetiziruyuschikh ustroystv transportnykh sistem. Dinamika sistem, mekhanizmov i mashin, 3 (1), 260–263.

- South, J. T. (2001). Mechanical properties and durability of natural rubber compounds and composites. Blacksburg, 190. Available at: https://vtechworks.lib.vt.edu/bitstream/handle/10919/26306/1JTS_ETD.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Oleg Dyshyn, Ibrahim Habibov, Arzu Suleymanova, Sevinc Abasova, Rauf Malikov, Tamila Khankishiyeva

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.