Revealing the influence of structural and operational parameters of a hydrostatic bearing in a gear-type fuel pump on its main characteristics

DOI:

https://doi.org/10.15587/1729-4061.2023.277755Keywords:

hydrostatic bearing, gear pump, carrying capacity, Reynolds equation, flow rate balanceAbstract

The object of this study is hydrostatic processes in the sliding supports of gear-type fuel pumps.

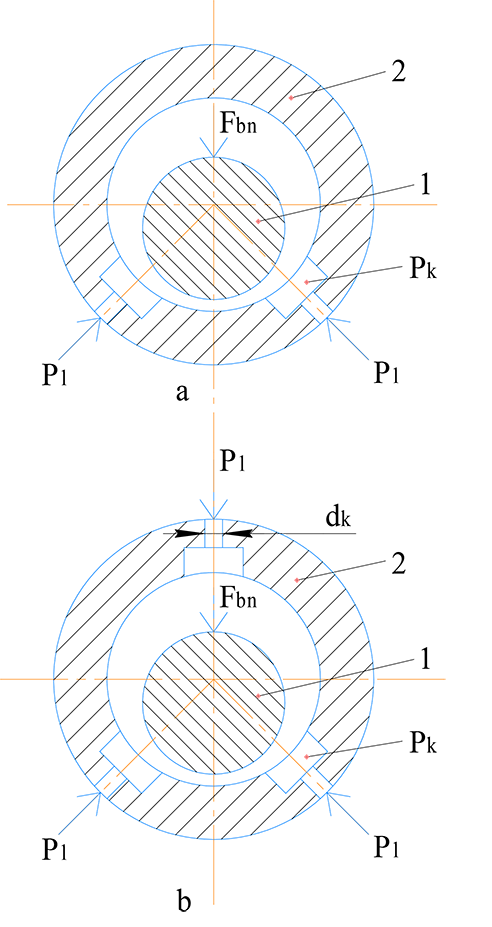

The problem solved was the influence of the structural and operational parameters of hydrostatic bearings of the fuel pump on their static characteristics. The carrying capacity and consumption of the lubricant were considered as static characteristics. The characterization was based on the function of distributing the pressure in the lubricant layer. It was determined from the joint solution of the Reynolds equations and the balance of costs. The carrying capacity of the bearing was determined by the numerical integration of the pressure distribution function in the lubricant layer. The lubricant consumption was determined by the calculated pressures in the chambers. Variants of the working surface of the bearing with two and three carrying chambers were considered. Due to the fact that the load in the pump acts in one direction during operation, the scheme of the working surface of the bearing with two carrying chambers was adopted. The fluid consumption of such a bearing was less compared to a bearing with three carrying chambers. One of the parameters that significantly affect the carrying capacity of the bearing is the diameter of the nozzle installed at the inlet to the chambers.

It has been established that the dependence of the carrying capacity of a hydrostatic bearing on the diameter of the nozzle is nonlinear. With an increase in the diameter of the nozzle from 1 mm to 2.3 mm, the carrying capacity of the bearing increased by about 2.83 times. The extraction of fuel for the operation of the hydrostatic bearing was 1 % of the fuel pumped by the pump.

The results make it possible to recommend hydrostatic bearings as shaft supports for gear-type fuel pumps and can be used for practical calculations

References

- Tacconi, J., Shahpar, S., King, A., Olufeagba, J. P., Khan, R., Sant, I., Yates, M. (2022). Elasto-Hydrodynamic Model of Hybrid Journal Bearings for Aero-Engine Gear Fuel Pump Applications. Journal of Tribology, 144 (3). doi: https://doi.org/10.1115/1.4052479

- Torrent, M., Gamez-Montero, P. J., Codina, E. (2021). Model of the Floating Bearing Bushing Movement in an External Gear Pump and the Relation to Its Parameterization. Energies, 14 (24), 8553. doi: https://doi.org/10.3390/en14248553

- Guerra, D., Polastri, M., Battarra, M., Suman, A., Mucchi, E., Pinelli, M. (2021). Design Multistage External Gear Pumps for Dry Sump Systems: Methodology and Application. Mathematical Problems in Engineering, 2021, 1–11. doi: https://doi.org/10.1155/2021/8888128

- Yang, H. (2020). Gear Pump Bearings-Reverse Design of Journal Fluid Lubrication. 2020 5th International Conference on Electromechanical Control Technology and Transportation (ICECTT). doi: https://doi.org/10.1109/icectt50890.2020.00013

- Zhu, J., Li, H., Wei, S., Fu, J., Xu, X. (2021). An approach of simulating journal bearings-gear pump system including components’ cavitation. Simulation Modelling Practice and Theory, 108, 102236. doi: https://doi.org/10.1016/j.simpat.2020.102236

- Pham, T. H. (2019). Hybrid method to analysis the dynamic behavior of the ring gear for the internal gear motors and pumps. Journal of Mechanical Science and Technology, 33 (2), 603–612. doi: https://doi.org/10.1007/s12206-019-0114-7

- Wei, S., Wang, J., Cui, J., Song, S., Li, H., Fu, J. (2022). Online monitoring of oil film thickness of journal bearing in aviation fuel gear pump. Measurement, 204, 112050. doi: https://doi.org/10.1016/j.measurement.2022.112050

- Pham, T. H., Nguyen, D. T., Weber, J. (2020). Theoretical, simulation and experimental investigation of 1D hybrid pressure distribution for internal gear motors and pumps. Journal of Mechanical Science and Technology, 34 (1), 97–108. doi: https://doi.org/10.1007/s12206-019-1209-x

- Fu, J., Jiang, Y., Li, H., Zhu, J. (2021). Optimization Design of Sliding Bearing of Fuel Pump Based on CFD Method. 2021 12th International Conference on Mechanical and Aerospace Engineering (ICMAE). doi: https://doi.org/10.1109/icmae52228.2021.9522403

- Li, D., He, Z., Sun, S., Xing, Z. (2022). Dynamic characteristics modelling and analysis for dry screw vacuum pumps. Vacuum, 198, 110868. doi: https://doi.org/10.1016/j.vacuum.2022.110868

- Saha, S., Nabi, M. (2019). Model Order Reduction of Axial Active Magnetic Bearing. 2019 9th International Conference on Cloud Computing, Data Science & Engineering (Confluence). doi: https://doi.org/10.1109/confluence.2019.8776931

- Zhuk, Y. (2019). Nanostructured CVD W/WC Coating Prevents Galling and Adhesive Wear of Mechanisms under Dry Sliding Conditions. Journal Metallurgia Italiana, 10, 45–53.

- Nazin, V. I. (2012). Research of capacity of hydrostatical bearing of hob type. Aviatsionno-kosmicheskaya tekhnika i tekhnologiya, 9, 99–104. Available at: http://nbuv.gov.ua/UJRN/aktit_2012_9_20

- Emtsev, B. T. (1978). Tekhnicheskaya gidromekhanika. Moscow: Mashinostroenие, 463.

- Uginchus, A. A., Chugaeva, E. A. (1971). Gidravlika. Leningrad: Stroyizdat, 350.

- Bogdanov, O. N., D'yachenko, S. K. (1966). Raschet opor skol'zheniya. Kyiv: Tekhnika, 242.

- Tipey, N., Konstantinesku, V. N., Nika, A., Bitse, O. (1964). Podshipniki skol'zheniya (raschet, proektirovanie, smazka). Bukharest: Izdatel'stvo Akad. Rum. Nar. Resp., 457.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Vladimir Nazin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.