Analysis of technological possibilities of N‒O‒C‒H system arc plasma in surface engineering processes

DOI:

https://doi.org/10.15587/1729-4061.2023.277756Keywords:

plasma-forming substance, plasma of the N‒O‒C‒H system, reducing components of plasma, oxidative-reducing potentialAbstract

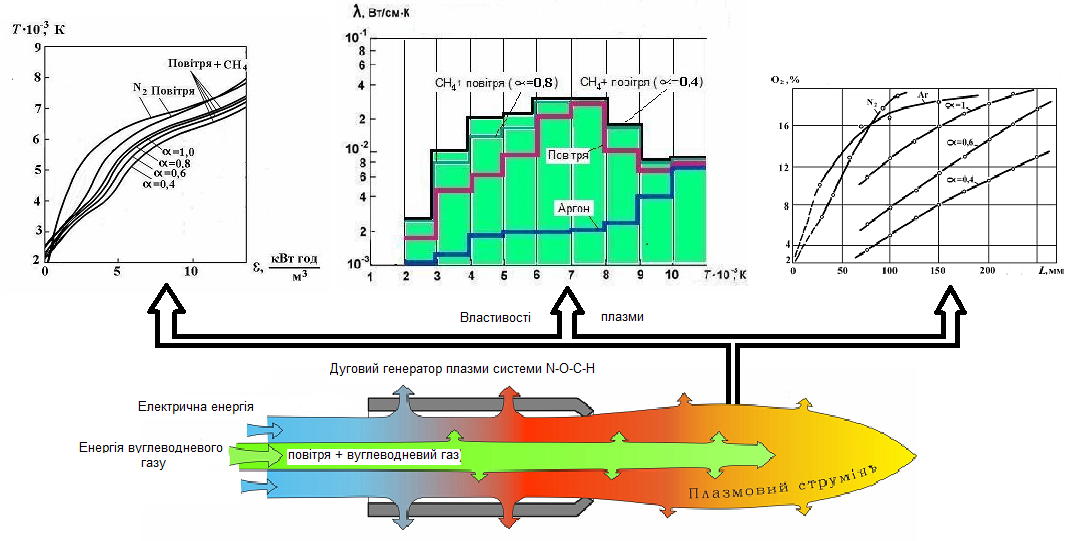

The object of this study was the substances that could be used to generate arc plasma. Conventional and promising plasma media were analyzed in order to identify the most universal one in terms of a set of properties for efficient energy transfer of material. It is shown that the mean-enthalpy media have a harmonious ratio of temperature and enthalpy and could provide a change in the energy state of the processed material with maximum efficiency. It is established that the most universal set of properties is demonstrated by the medium enthalpy plasma of the N‒O‒C‒H system. The use of mixtures of air with hydrocarbons for its generation makes it possible to reach the average mass temperature of (5...7)·103 K and change the oxidative-reducing potential of the plasma medium over a wide range. Given this, heat treatment is possible with maximum preservation of the original composition of the material. Experimental studies of plasma flows of the N‒O‒C‒H system confirmed the presence of reducing components capable of binding oxygen to air that is sucked into the jet. On rich mixtures, the oxygen content in the jet at a distance of 100 mm does not exceed 5 %.

The positive effect of combined energy input into plasma-forming substance on the process of generation and formation of plasma jet has been proven. The use of energy of different physical nature makes it possible to maintain the local energy parameters of the plasma flow during material processing. This is due to the release of additional heat as a result of the interaction of plasma and plasma components with ambient air. The use of plasma of the N‒O‒C‒H system in surface engineering technologies could expand the range of processed materials and reduce the operating costs of the process

References

- External atmospheric plasma. Available at: https://www.oerlikon.com/metco/en/products-services/thermal-spray-equipment/thermal-spray-components/spray-guns/plasma/?tab=external_atmospheric_plasma

- Samal, S., Blanco, I. (2022). An Overview of Thermal Plasma Arc Systems for Treatment of Various Wastes in Recovery of Metals. Materials, 15 (2), 683. doi: https://doi.org/10.3390/ma15020683

- Babu, A., Dzhurinskiy, D., Dautov, S., Shornikov, P. (2023). Structure and electrochemical behavior of atmospheric plasma sprayed Cr3C2-NiCr cermet composite coatings. International Journal of Refractory Metals and Hard Materials, 111, 106105. doi: https://doi.org/10.1016/j.ijrmhm.2023.106105

- Atmospheric Plasma Spray Solutions. Available at: https://smsbbtim.com/wp-content/uploads/2016/08/Plasma_Solutions_EN5.pdf

- Plasma. Equipment Solutions. Available at: https://www.praxairsurfacetechnologies.com/-/media/corporate/praxairsurface/us/documents/brochures/plasma-brochure.pdf?la=en

- Lynam, A., Rincon Romero, A., Xu, F., Bai, M., Hussain, T. (2022). Atmospheric Plasma Spraying of Environmental Barrier Coatings – A Parametric Study. Thermal Spray 2022: Proceedings from the International Thermal Spray Conference. doi: https://doi.org/10.31399/asm.cp.itsc2022p0001

- Borysov, Yu. S., Borysova, A. L., Vigilyanska, N. V., Gryshchenko, O. P., Kolomytsev, M. V. (2020). Coatings based on Fe–Al intermetallics produced by the methods of plasma and supersonic plasma gas-air spraying. The Paton Welding Journal, 2020 (7), 29–37. doi: https://doi.org/10.37434/tpwj2020.07.04

- Korzhyk, V. M., Khaskin, V. Yu., Yuhui, Y., Demianov, O. I., Strogonov, D. V., Shcheretskyi, V. O. (2022). Influence of accompanying compressing air flow on the coating structure and properties in plasma-arc spraying by consumable current-conducting wire. The Paton Welding Journal, 2022 (2), 3–10. doi: https://doi.org/10.37434/tpwj2022.02.01

- Pashchenko, V. M. (2018). Duhovi heneratory v tekhnolohiyakh inzheneriyi poverkhni. Kharkiv: Machulin, 288.

- Khasuy, A. (1975). Tekhnika napyleniya. Moscow: Mashinostroenie, 288.

- Bondarenko, B. I. (1980). Vosstanovlenie okislov metallov v slozhnykh gazovykh sistemakh. Kyiv: Naukova dumka, 385.

- Pashchenko, V. (2017). Research into the energy conversion processes in hybrid plasma devices for applying the coatings. Eastern-European Journal of Enterprise Technologies, 2 (5 (86)), 44–51. doi: https://doi.org/10.15587/1729-4061.2017.95578

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Valeriy Pashchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.