Determination of the ballistic performance ramie-fiber-reinforced epoxy composite-sic ceramic in multilayered armor system

DOI:

https://doi.org/10.15587/1729-4061.2023.277914Keywords:

ballistic performance study, multilayered armor system, SiC, ramie, back face signatureAbstract

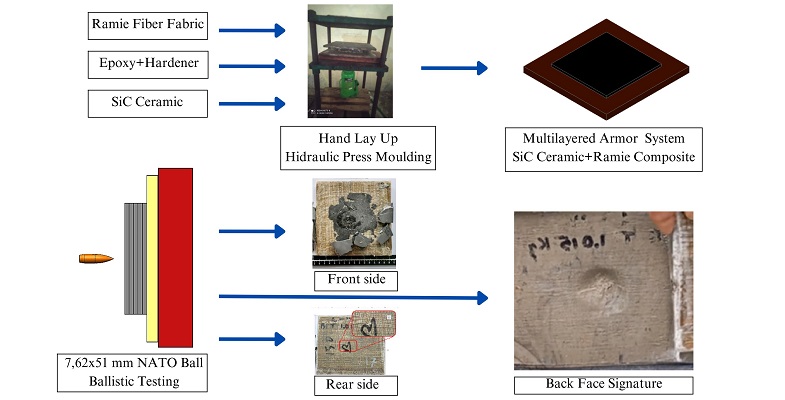

Multilayered Armor System (MAS) is being extensively studied around the world for its ability to retain ceramic fragmentation after a collision occurs. MAS consist of a ceramic layer placed at the front and supported by a composite layer of ramie-fiber-reinforced epoxy resin. Present study utilizes natural fibers of 50 % ramie fibers with epoxy resin as the matrix and Silicon Carbide (SiC) ceramic as the front panel. The ballistic testing in this study used 7.62×51 mm NATO Ball projectile with a firing distance of 15 m from the bullet panel. The velocity of projectile was detected using LIGHT SCREEN B471 type. The aim of the study is to conclude the optimal thickness of ramie fiber-epoxy and SiC ceramics MAS structure based on experiments which can withstand 7.62 NATO ball bullet penetration. To achieve this aim, the following objectives are accomplished: study the effect of SiC ceramic addition to ramie composite on BFS and study the effect of SiC ceramic addition to ramie composite on failure mode. Results show that the addition of the number of layers of SiC increases resistance of ballistic MAS marked by a decrease in the value of BFS clay. The 5SiC+10R is the optimal thickness in resisting the penetration of 7.62×51 mm bullets with 12 mm BFS clay. Failure phenomena found in this study were projectile fragments, matrix cracks, radial cracks, impact points, and ceramic fragments. Matrix crack formation appears on 5SiC+10R with mini deformation in rear side. Phenomenon of ceramic fragmentation in the shot causes the MAS structure to be damaged, so that the ramie fiber composite layer will face the bullet directly if it is subjected to a second shot. Ultra High Hardness Armor (UHHA) as first layer on the MAS structure is an attractive option for further research.

Supporting Agency

- The authors fully acknowledged Universitas Diponegoro for the approved fund which makes this research can be done effectively.

References

- Chabera, P., Boczkowska, A., Morka, A., Kędzierski, P., Niezgoda, T., Oziębło, A., Witek, A. (2015). Comparison of numerical and experimental study of armour system based on alumina and silicon carbide ceramics. Bulletin of the Polish Academy of Sciences Technical Sciences, 63 (2), 363–367. doi: https://doi.org/10.1515/bpasts-2015-0040

- Crouch, I. G. (2019). Body armour – New materials, new systems. Defence Technology, 15 (3), 241–253. doi: https://doi.org/10.1016/j.dt.2019.02.002

- Medvedovski, E. (2010). Ballistic performance of armour ceramics: Influence of design and structure. Part 1. Ceramics International, 36 (7), 2103–2115. doi: https://doi.org/10.1016/j.ceramint.2010.05.021

- Louro, L. H. L., Meyers, M. A. (1989). Effect of stress state and microstructural parameters on impact damage of alumina-based ceramics. Journal of Materials Science, 24 (7), 2516–2532. doi: https://doi.org/10.1007/bf01174523

- Odesanya, K. O., Ahmad, R., Jawaid, M., Bingol, S., Adebayo, G. O., Wong, Y. H. (2021). Natural Fibre-Reinforced Composite for Ballistic Applications: A Review. Journal of Polymers and the Environment, 29 (12), 3795–3812. doi: https://doi.org/10.1007/s10924-021-02169-4

- Monteiro, S. N., Milanezi, T. L., Louro, L. H. L., Lima, É. P., Braga, F. O., Gomes, A. V., Drelich, J. W. (2016). Novel ballistic ramie fabric composite competing with Kevlar™ fabric in multilayered armor. Materials & Design, 96, 263–269. doi: https://doi.org/10.1016/j.matdes.2016.02.024

- Nurhadiyanto, D., Mujiyono, Mukhammad, A. F. H., Setyoko, M. B., bin Yahya, M. Y., Riyadi, T. W. B. (2021). Drop test resistance on ramie fiber bulletproof panels based on harvest time and fiber treatment of ramie. Composites: Mechanics, Computations, Applications: An International Journal, 12 (1), 1–16. doi: https://doi.org/10.1615/compmechcomputapplintj.2020035788

- Marsyahyo, E., Jamasri, Heru Santoso Budi Rochardjo, Soekrisno (2009). Preliminary Investigation on Bulletproof Panels Made from Ramie Fiber Reinforced Composites for NIJ Level II, IIA, and IV. Journal of Industrial Textiles, 39 (1), 13–26. doi: https://doi.org/10.1177/1528083708098913

- Mukhammad, A. F. H., Murni, Mujiyono, Nurhadiyanto, D., Hassan, S. A., Riyadi, T. W. B. (2020). Preliminary study of fragment simulating projectile on epoxy-ramie composite. Journal of Physics: Conference Series, 1446 (1), 012001. doi: https://doi.org/10.1088/1742-6596/1446/1/012001

- Neves Monteiro, S., Salgado de Assis, F., Ferreira, C., Tonini Simonassi, N., Pondé Weber, R., Souza Oliveira, M. et al. (2018). Fique Fabric: A Promising Reinforcement for Polymer Composites. Polymers, 10 (3), 246. doi: https://doi.org/10.3390/polym10030246

- Assis, F. S. de, Pereira, A. C., Filho, F. da C. G., Lima, É. P., Monteiro, S. N., Weber, R. P. (2018). Performance of jute non-woven mat reinforced polyester matrix composite in multilayered armor. Journal of Materials Research and Technology, 7 (4), 535–540. doi: https://doi.org/10.1016/j.jmrt.2018.05.026

- Braga, F. de O., Bolzan, L. T., Luz, F. S. da, Lopes, P. H. L. M., Lima Jr., É. P., Monteiro, S. N. (2017). High energy ballistic and fracture comparison between multilayered armor systems using non-woven curaua fabric composites and aramid laminates. Journal of Materials Research and Technology, 6 (4), 417–422. doi: https://doi.org/10.1016/j.jmrt.2017.08.001

- Nascimento, L. F. C., Louro, L. H. L., Monteiro, S. N., Lima, É. P., da Luz, F. S. (2017). Mallow Fiber-Reinforced Epoxy Composites in Multilayered Armor for Personal Ballistic Protection. JOM, 69 (10), 2052–2056. doi: https://doi.org/10.1007/s11837-017-2495-3

- Neves Monteiro, S., de Oliveira Braga, F., Pereira Lima, E., Henrique Leme Louro, L., Wieslaw Drelich, J. (2016). Promising curaua fiber-reinforced polyester composite for high-impact ballistic multilayered armor. Polymer Engineering & Science, 57 (9), 947–954. doi: https://doi.org/10.1002/pen.24471

- Hu, D., Zhang, Y., Shen, Z., Cai, Q. (2017). Investigation on the ballistic behavior of mosaic SiC/UHMWPE composite armor systems. Ceramics International, 43 (13), 10368–10376. doi: https://doi.org/10.1016/j.ceramint.2017.05.071

- Product categories: SiC ceramics. Sancera. Available at: https://www.china-sancera.com/?products_9/

- Flores-Johnson, E. A., Saleh, M., Edwards, L. (2011). Ballistic performance of multi-layered metallic plates impacted by a 7.62-mm APM2 projectile. International Journal of Impact Engineering, 38 (12), 1022–1032. doi: https://doi.org/10.1016/j.ijimpeng.2011.08.005

- Kumar, S., Malek, A., Babu, R., Mathur, S. (2021). Ballistic Efficiency of Multilayered Armor System Reinforced with Jute-Kevlar Epoxy Composite against High-Energy Steel Core Projectile. Journal of Materials Engineering and Performance, 30 (11), 8447–8464. doi: https://doi.org/10.1007/s11665-021-06057-9

- Gupta, J. K. (2018). Salient features of Indian Standard on Bullet resistant jackets (IS 17051:2018). Available at: https://ficci.in/events/24084/ISP/BRJ.pdf

- Mukasey, M. B., Sedgwick, J. L., Hagy, D. W. (2008). Ballistic Resistance of Body Armor. NIJ Standard-0101.06. Available at: https://www.ojp.gov/pdffiles1/nij/223054.pdf

- Monteiro, S. N., Lima, É. P., Louro, L. H. L., da Silva, L. C., Drelich, J. W. (2014). Unlocking Function of Aramid Fibers in Multilayered Ballistic Armor. Metallurgical and Materials Transactions A, 46 (1), 37–40. doi: https://doi.org/10.1007/s11661-014-2678-2

- Luz, F. S. da, Lima Junior, E. P., Louro, L. H. L., Monteiro, S. N. (2015). Ballistic Test of Multilayered Armor with Intermediate Epoxy Composite Reinforced with Jute Fabric. Materials Research, 18, 170–177. doi: https://doi.org/10.1590/1516-1439.358914

- Mujiyono, M., Nurhadiyanto, D., Mukhammad, A. F. H., Riyadi, T. W. B., Wahyudi, K., Kholis, N. et al. (2023). Damage formations of ramie fiber composites multilayer armour system under high-velocity impacts. Eastern-European Journal of Enterprise Technologies, 1 (12 (121)), 16–25. doi: https://doi.org/10.15587/1729-4061.2023.273788

- Bekci, M. L., Canpolat, B. H., Usta, E., Güler, M. S., Cora, Ö. N. (2021). Ballistic performances of Ramor 500 and Ramor 550 armor steels at mono and bilayered plate configurations. Engineering Science and Technology, an International Journal, 24 (4), 990–995. doi: https://doi.org/10.1016/j.jestch.2021.01.001

- Nascimento, L. F. C., Louro, L. H. L., Monteiro, S. N., Gomes, A. V., Marçal, R. L. S. B., Lima Júnior, É. P., Margem, J. I. (2017). Ballistic Performance of Mallow and Jute Natural Fabrics Reinforced Epoxy Composites in Multilayered Armor. Materials Research, 20, 399–403. doi: https://doi.org/10.1590/1980-5373-mr-2016-0927

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Alaya Fadllu Hadi Mukhammad, Rusnaldy, Rifky Ismail, Tri Widodo Besar Riyadi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.