Determining the patterns of extinguishing polar flammable liquids with a film-forming foaming agent

DOI:

https://doi.org/10.15587/1729-4061.2023.278910Keywords:

foaming agent for extinguishing fires, foam inflow, foam resistance, isolating of flammable liquidAbstract

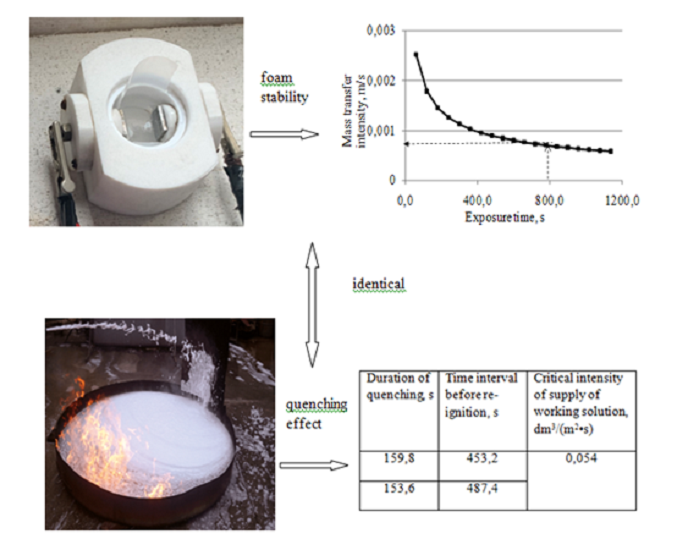

An issue related to the use of foaming agents to extinguish fires involving flammable liquids is to ensure the efficiency of vapor insulation of flammable liquid and the foam stability during operation. Therefore, the object of research was a change in the insulating properties of the foaming agent film when interacting with a polar combustible substance. It has been proven that the presence of foaming agent on a flammable liquid leads to the formation of an insulating film on the surface resistant to the combustion temperature of the liquid, due to which re-ignition shifts towards longer time. A film of foaming agent was formed on the surface of the flammable liquid by leaking from the screen, which led to the insulation of the surface. The measured contact area of the foaming film with the electrode was more than 6.2·10-3 m2, which indicates the formation of a barrier for temperature, which collapses over time. According to experimental data on changes in electrical resistance, the critical contact area of the foaming film with the electrode was calculated, at which the film is destroyed. Based on the derived dependences, the change in the process of mass transfer of the foaming film to a flammable liquid was calculated, equal to about 800 s. The maximum possible mass transfer of the foaming agent into the flammable liquid and the reduction of insulation capacity were evaluated. The peculiarities of foam supply to the surface of alcohol through the screen are that the quenching time was about 156 s while the critical intensity of the supply of the working solution of the foaming agent was 0.054 dm3/(m2·s). And the time interval before re-ignition was about 470 s, which is enough to cool the fire site. Thus, there is reason to assert the possibility of targeted control over the processes of extinguishing polar flammable liquids with a foaming agent

References

- Degaev, E. (2018). New classification of foaming agents for fire extinguishing. MATEC Web of Conferences, 193, 02032. doi: https://doi.org/10.1051/matecconf/201819302032

- Tian, C., Zhao, J., Yang, J., Zhang, J., Yang, R. (2023). Preparation and characterization of fire-extinguishing efficiency of novel gel-protein foam for liquid pool fires. Energy, 263, 125949. doi: https://doi.org/10.1016/j.energy.2022.125949

- Kang, W., Yan, L., Ding, F., Guo, X., Xu, Z. (2019). Experimental study on fire-extinguishing efficiency of protein foam in diesel pool fire. Case Studies in Thermal Engineering, 16, 100557. doi: https://doi.org/10.1016/j.csite.2019.100557

- Zhou, J., Ranjith, P. G., Wanniarachchi, W. A. M. (2020). Different strategies of foam stabilization in the use of foam as a fracturing fluid. Advances in Colloid and Interface Science, 276, 102104. doi: https://doi.org/10.1016/j.cis.2020.102104

- Oguike, R. (2013). Study of fire fighting foam agent from palm oil for extinguishing of petrol fires. Science Postprint, 1 (1). doi: https://doi.org/10.14340/spp.2013.12a0002

- Zhang, J., Shang, F., Zhou, W., Xiao, F., Cheng, D. (2022). Fire-extinguishing performance and gas-phase pollution characteristics of different foam agents in extinguishing transformer oil pool fire. Journal of Fire Sciences, 40 (6), 463–478. doi: https://doi.org/10.1177/07349041221142509

- Rabajczyk, A., Zielecka, M., Gniazdowska, J. (2022). Application of Nanotechnology in Extinguishing Agents. Materials, 15 (24), 8876. doi: https://doi.org/10.3390/ma15248876

- Li, Z., Zhu, H., Zhao, J., Zhang, Y., Hu, L. (2022). Experimental Research on the Effectiveness of Different Types of Foam of Extinguishing Methanol / Diesel Pool Fires. Combustion Science and Technology, 1–19. doi: https://doi.org/10.1080/00102202.2022.2125306

- Jia, X., Luo, Y., Huang, R., Bo, H., Liu, Q., Zhu, X. (2020). Spreading kinetics of fluorocarbon surfactants on several liquid fuels surfaces. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 589, 124441. doi: https://doi.org/10.1016/j.colsurfa.2020.124441

- Sheng, Y., Lu, S., Xu, M., Wu, X., Li, C. (2015). Effect of Xanthan Gum on the Performance of Aqueous Film-Forming Foam. Journal of Dispersion Science and Technology, 37 (11), 1664–1670. doi: https://doi.org/10.1080/01932691.2015.1124341

- He, Y.-H., Sun, Q., Xing, H., Wu, Y., Xiao, J.-X. (2018). Cationic–anionic fluorinated surfactant mixtures based on short fluorocarbon chains as potential aqueous film-forming foam. Journal of Dispersion Science and Technology, 40 (3), 319–331. doi: https://doi.org/10.1080/01932691.2018.1468262

- Hinnant, K. M., Conroy, M. W., Ananth, R. (2017). Influence of fuel on foam degradation for fluorinated and fluorine-free foams. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 522, 1–17. doi: https://doi.org/10.1016/j.colsurfa.2017.02.082

- Tsapko, Y., Rogovskii, I., Titova, L., Bilko, T., Tsapko, А., Bondarenko, O., Mazurchuk, S. (2020). Establishing regularities in the insulating capacity of a foaming agent for localizing flammable liquids. Eastern-European Journal of Enterprise Technologies, 5 (10 (107)), 51–57. doi: https://doi.org/10.15587/1729-4061.2020.215130

- ISO 7203-1:2019. Fire extinguishing media – Foam concentrates – Part 1: Specification for low-expansion foam concentrates for top application to water-immiscible liquids. Available at: https://www.iso.org/standard/70452.html

- EN 1568-1:2008. Fire extinguishing media - Foam concentrates - Part 1: Specification for medium expansion foam concentrates for surface application to water-immiscible liquids. Available at: https://standards.iteh.ai/catalog/standards/cen/5221b2b6-d69c-435e-b202-9d93a024992a/en-1568-1-2008

- Potter, M. C. (2019). Engineering analysis. Springer, 434. doi: https://doi.org/10.1007/978-3-319-91683-5

- Tsapko, Y., Sirko, Z., Vasylyshyn, R., Melnyk, O., Tsapko, А., Bondarenko, O., Karpuk, A. (2021). Establishing patterns of mass transfer under the action of water on the hydrophobic coating of the fire-retardant element of a tent. Eastern-European Journal of Enterprise Technologies, 4 (10 (112)), 45–51. doi: https://doi.org/10.15587/1729-4061.2021.237884

- Tsapko, Y., Horbachova, O., Mazurchuk, S., Tsapko, А., Sokolenko, K., Matviichuk, A. (2022). Establishing regularities of wood protection against water absorption using a polymer shell. Eastern-European Journal of Enterprise Technologies, 1 (10 (115)), 48–54. doi: https://doi.org/10.15587/1729-4061.2022.252176

- Hamer, W. J., DeWane, H. J. (1970). Electrolytic conductance and the conductances of the halogen acids in water. NSRDS. doi: https://doi.org/10.6028/nbs.nsrds.33

- Movchan, T. G., Rusanov, A. I., Soboleva, I. V., Khlebunova, N. R., Plotnikova, E. V., Shchekin, A. K. (2015). Diffusion coefficients of ionic surfactants with different molecular structures in aqueous solutions. Colloid Journal, 77 (4), 492–499. doi: https://doi.org/10.1134/s1061933x15040146

- Tsapko, Y., Tsapko, А. (2017). Influence of dry mixtures in a coating on the effectiveness of wood protection from the action of a magnesium flame. Eastern-European Journal of Enterprise Technologies, 5 (10 (89)), 55–60. doi: https://doi.org/10.15587/1729-4061.2017.111106

- Tsapko, Y., Sokolenko, K., Vasylyshyn, R., Melnyk, O., Tsapko, А., Bondarenko, O., Karpuk, A. (2022). Establishing patterns of nitrogen application for fire safety of sunflower grain storage facilities. Eastern-European Journal of Enterprise Technologies, 5 (10 (119)), 57–65. doi: https://doi.org/10.15587/1729-4061.2022.266014

- Tsapko, Y., Rogovskii, I., Titova, L., Shatrov, R., Tsapko, А., Bondarenko, O., Mazurchuk, S. (2020). Establishing patterns of heat transfer to timber through a protective structure. Eastern-European Journal of Enterprise Technologies, 6 (10 (108)), 65–71. doi: https://doi.org/10.15587/1729-4061.2020.217970

- Tsapko, Y., Guzii, S., Remenets, M., Kravchenko, A., Tsapko, O. (2016). Evaluation of effectiveness of wood fire protection upon exposure to flame of magnesium. Eastern-European Journal of Enterprise Technologies, 4 (10 (82)), 31–36. doi: https://doi.org/10.15587/1729-4061.2016.73543

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yuriy Tsapko, Ruslan Likhnyovskyi, Аleksii Tsapko, Vitalii Kovalenko, Oksana Slutska, Pavlo Illiuchenko, Kostiantyn Sokolenko, Yuri Gulyk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.