A research of the effect of an underwater electric explosion on the selectivity of destruction of quartz raw materials

DOI:

https://doi.org/10.15587/1729-4061.2023.279009Keywords:

quartz ore, crushing, electric explosion, discharge channel, capacitor, stoichiometry, energy spectrumAbstract

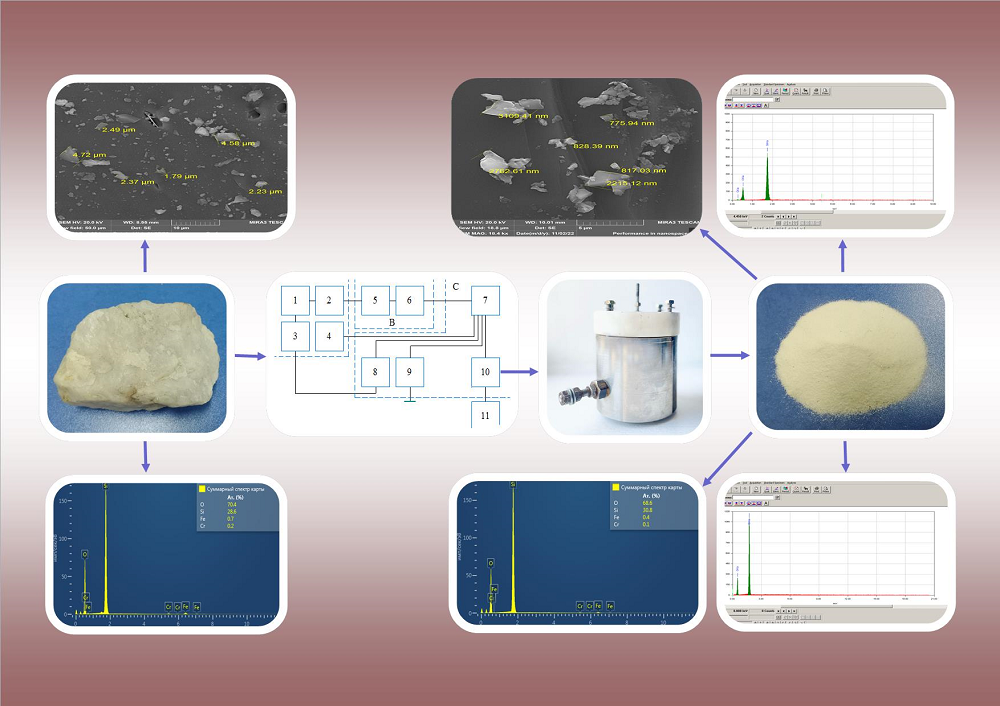

The work is devoted to the study of the effect of an electric explosion on the selectivity of the destruction of quartz raw materials. The object of the study is quartz ore of the Nadyrbay deposit of the Republic of Kazakhstan. An electrohydroimpulse plant for crushing and grinding quartz raw materials has been developed and assembled. Using the electrohydroimpulse method, the granulometric composition of quartz can be adjusted. This makes it possible to adjust the magnitude of the voltage in the discharge channel and time. In this technology, quartz ore processing was carried out with an increase in the discharge voltage of the storage from 14 kV to 25 kV, the length of the interelectrode distance from 8 to 12, the capacitance of the capacitor 0.5 µF, 0.75 µF and the processing time of 5 min. Using the electrohydroimpulse method, quartz ore particles with an initial fraction of 5 mm, 10 mm and 1 mm were crushed to 0.8. The results of the grinding of quartz raw materials with the influence of an underwater electric explosion in a liquid medium allowed us to determine the degree of grinding of the material.

The obtained results can be used in the course of studying the characteristics of crushing and grinding of ores. In the food industry, quartz sand within 0.25–0.5 millimeters can be used as a filler to create filters for water purification, as well as products from oil, industrial effluents, etc. Particles ranging in size from 0.5 to 1 millimeter can be used for rough processing of metal, stone and glass.

The structural and quantitative analysis of powdered quartzite samples was made using a scanning electron microscope and the stoichiometry of the elements was calculated

Supporting Agency

- This research is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant AP14870607).

References

- Yutkin, L. A. (1986). Elektpogidpavlicheckiy effekt i ego ppimenenie v ppomyshlennocti. Leningrad: Mashinoctpoenie, 253.

- Martynov, N. V., Dobromirov, V. N., Barsukov, V. O., Avramov, D. V. (2021). Electrohydraulic Technology for Breaking Solid Objects. Mining Industry Journal (Gornay Promishlennost), 2, 132–136. doi: https://doi.org/10.30686/1609-9192-2021-2-132-136

- Kulinich, V. V., Sagunov, V. G., Uzhkenov, B. S. et al. (2000). Mectopozhdeniya gopnopudnogo syr'ya Kazakhctana. Almaty, 372.

- Bur'yan, Yu. I. (2007). Kvartsevoe syr'e – vazhneyshiy vid mineral'nykh resursov dlya vysokotekhnologichnykh otrasley promyshlennosti. Razvedka i okhrana nedr, 10.

- Kuz'mina, N. I. (2007). Kriterii opredeleniya predelov obogatimosti razlichnykh prirodnykh tipov kvartsevogo syr'ya. Razvedka i okhrana nedr, 10.

- Gupta, V. K. (2023). Hold-up weight in continuous wet ball milling: Relationship with the size distribution of the particulate contents of the mill. Powder Technology, 415, 118137. doi: https://doi.org/10.1016/j.powtec.2022.118137

- Yang, J., Zhu, P., Li, H., Li, Z., Huo, X., Ma, S. (2022). Research on the Relationship between Multi-Component Complex Ore and Its Component Minerals’ Grinding Characteristics under Abrasion Force. Minerals, 13 (1), 6. doi: https://doi.org/10.3390/min13010006

- Gao, P., Qin, Y., Zhang, H., Chen, H. (2022). Strengthening the magnetic separation characteristic of magnetite quartzite via high-voltage pulse discharge. Canadian Metallurgical Quarterly, 62 (1), 85–98. doi: https://doi.org/10.1080/00084433.2022.2071090

- Gao, P., Yuan, S., Han, Y., Li, Y., Chen, H. (2017). Experimental Study on the Effect of Pretreatment with High-Voltage Electrical Pulses on Mineral Liberation and Separation of Magnetite Ore. Minerals, 7 (9), 153. doi: https://doi.org/10.3390/min7090153

- Chanturiya, V. A., Bunin, I. Zh. (2022). Advances in Pulsed Power Mineral Processing Technologies. Minerals, 12 (9), 1177. doi: https://doi.org/10.3390/min12091177

- Rostovtsev, V. I., Bryazgin, A. A., Korobeinikov, M. V. (2020). Improvement of milling selectivity and utilization completeness through radiation modification of mineral properties. Journal of Mining Science, 56 (6), 1000–1009. doi: https://doi.org/10.1134/s1062739120060125

- Nesterova, T. N., Vostrikov, S. V. (2014). Stekhiometriya, material'nye i energeticheskie raschety v khimii i khimicheskoy tekhnologii. Samara: SamGTU, 403.

- Kurytnik, I. P., Rakishevich, B., Nussupbekov, B. R., Khassenov, A. K., Karabekova, D. Z., Tanasheva, N. K. (2020). About an electric pulse method of grinding gold ore. Przegląd Elektrotechniczny, 1 (10), 150–152. doi: https://doi.org/10.15199/48.2020.10.27

- Bulkairova, G. A., Stoev, M., Khassenov, A. K., Karabekova, D. Zh., Nurgaliyeva, Zh. G., Kipshakov, M. S. (2019). Effects of electrohydroimpulse discharges on the crushing of the natural mineral quartz. Eurasian Physical Technical Journal, 16 (2), 89–93. doi: https://doi.org/10.31489/2019no2/89-93

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Gulden Bulkairova, Bekbolat Nussupbekov, Madina Bolatbekova, Ayanbergen Khassenov, Ulan Nussupbekov, Dana Karabekova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.